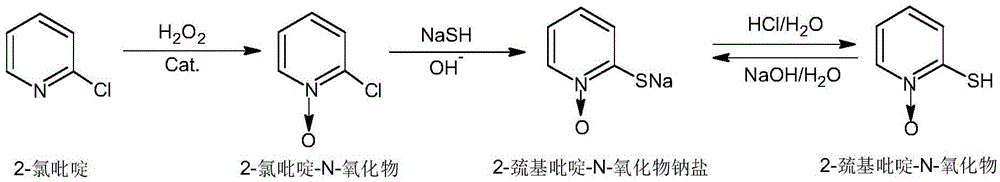

Method for removing 2-mercaptopyridine-N-oxide in wastewater and recycling of 2-mercaptopyridine-N-oxide

A technology of pyrithione and oxide, which is applied to a method of removing 2-pyridine-N-oxide in wastewater and its recycling field, which can solve problems such as pollution and low content of pyrithione zinc, and achieve green process Environmental protection, chromaticity and suspended solids reduction, content reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In a 5L glass reaction bottle, add 0.5 kg of toluene, add 4.5 kg of waste water containing 2-mercaptopyridine-N-oxide whose pH value was adjusted to 3-4 in advance, stir at room temperature for 1 hour, and sample the waste water for analysis. The waste water contains 0.042% of 2-mercaptopyridine-N-oxide, which is allowed to stand still for 0.5 hour, separated into layers, and the waste water layer is separated.

[0023] After the stratification is completed, add 0.01kg of deionized water, add 0.015kg of 30% sodium hydroxide solution dropwise, until the pH value is 9, stir for 0.5 hours, let stand for 0.5 hours, separate layers, separate the water layer 0.039kg, and its 2-mercapto The content of pyridine-N-oxide sodium salt was 40.3%.

Embodiment 2

[0025] In a 5L glass reaction bottle, add 0.6kg of dichloromethane, add 4.5kg of wastewater containing 2-mercaptopyridine-N-oxide with a pH value of 2-3, stir at room temperature for 1 hour, and sample and analyze the wastewater. Contain 0.033% of 2-mercaptopyridine-N-oxide, let stand for 0.5 hour, separate layers, and separate the waste water layer.

[0026] After the stratification is completed, add 0.015kg of deionized water, dropwise add 0.016kg of 30% sodium hydroxide solution, until the pH value is 9, stir for 0.5 hours, let stand for 0.5 hours, separate layers, separate the water layer 0.046kg, its 2-mercapto Pyridine-N-oxide sodium salt content was 35.5%.

Embodiment 3

[0028] In a 5L glass reaction bottle, add 0.5kg of methyl tert-butyl ether, add 4.5kg of waste water containing 2-mercaptopyridine-N-oxide whose pH value was adjusted to 4-5 in advance, stir at room temperature for 1 hour, and the waste water Sampling and analysis showed that the 2-mercaptopyridine-N-oxide contained in the waste water was 0.038%. After standing for 0.5 hour, the waste water layer was separated into layers.

[0029] After the stratification is completed, add 0.01kg of deionized water, dropwise add 0.015kg of 30% sodium hydroxide solution, until the pH value is 9, stir for 0.5 hours, let stand for 0.5 hours, separate layers, separate the water layer 0.04kg, its 2-mercapto The content of pyridine-N-oxide sodium salt was 40.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com