Boron carbide/silicon carbide ceramic entire board and preparation method and application thereof

A silicon carbide ceramic and boron carbide technology, which is applied to the whole boron carbide/silicon carbide ceramic plate and its preparation field, can solve the problems of poor comfort of the bulletproof plate, affecting the ballistic resistance of the bulletproof plate, etc., so as to achieve improved ballistic resistance and good comfort. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

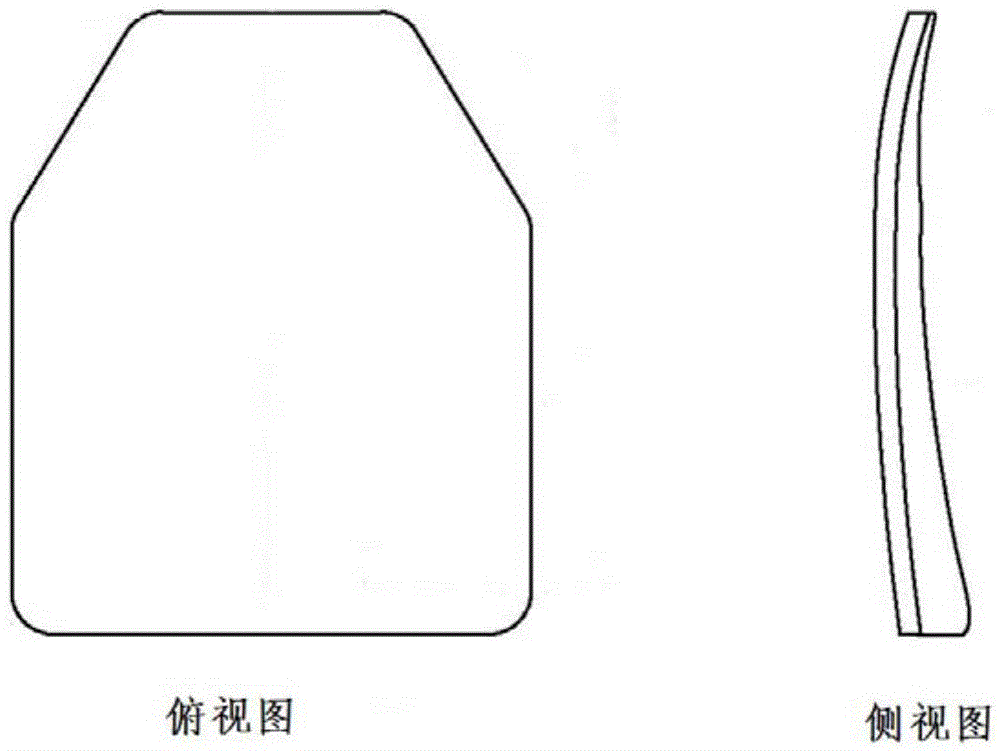

[0052] Example 1. Preparation of multi-curved boron carbide / silicon carbide ceramic whole board

[0053] Prepare a multi-curved boron carbide / silicon carbide ceramic whole plate as follows:

[0054] (1) Boron carbide powder 90g (D 50 : 0.7μm), silicon carbide powder 1500g (D 50 : 0.5 μm), coke 20g (particle size is 5 μm), deionized water 1500g are added in the ball mill, add 10g dispersant (tetramethylammonium hydroxide) and 8g binding agent (dextrin) and carry out ball mill pulping, get slurry Material (solid content is 48%); Ball milling condition is as follows: adopt boron carbide ceramic ball as the medium ball during ball milling, and ball diameter is 10mm, and the ratio of ball material ratio namely the weight of medium ball and powder material total weight is 1.5:1, The mixing time of the ball mill was 40 hours, the pH value of the slurry was 10.1, and the rotational speed of the ball mill was 150 rpm.

[0055] (2) The slurry obtained in step (1) is subjected to spra...

Embodiment 2

[0059] Example 2, preparation of multi-curved boron carbide / silicon carbide ceramic whole board

[0060] Prepare a multi-curved boron carbide / silicon carbide ceramic whole plate as follows:

[0061] (1) Boron carbide powder 80g (D 50 : 0.5μm), silicon carbide powder 1300g (D50: 0.4μm), graphite powder 80g (particle size 5μm), deionized water 1300g into the ball mill, add 8g dispersant (PVB) and 6g binder (PVA) Ball milling (the conditions and process of ball milling pulping are as in Example 1) to obtain slurry (solid content is 47%, pH value is 10.3).

[0062] (2) The slurry obtained in step (1) is subjected to spray granulation to obtain granulated material, specifically: after the slurry is passed through a 300-mesh sieve, the slurry is sent to the centrifugal turntable of the centrifugal drying granulator with a constant flow pump , the rotational speed of the centrifugal turntable is 5000 revolutions per minute to form tiny mist droplets, the inlet temperature of the dr...

Embodiment 3

[0066] Example 3, preparation of multi-curved boron carbide / silicon carbide ceramic whole board

[0067] Prepare a multi-curved boron carbide / silicon carbide ceramic whole plate as follows:

[0068] (1) Boron carbide powder 40g (D 50 : 0.5μm), silicon carbide powder 1350g (D50: 0.5μm), carbon black 50g (particle size 2μm), deionized water 1500g into the ball mill, add 10g dispersant (tetramethylammonium hydroxide) and 8g adhesive agent (dextrin) for ball milling (ball milling conditions and process are as in Example 1) to obtain slurry (solid content is 50%, pH value is 10.0).

[0069] (2) the slurry obtained in step (1) is passed through the granulated powder of spray granulation, specifically: after the slurry is passed through a 300-mesh sieve, the slurry is sent to the nozzle of the spray drying granulator with a constant flow pump, The pressure is 0.3 MPa to form tiny mist droplets, the inlet temperature of the dryer is 230° C., and the outlet temperature is 120° C. to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com