Watermelon anticracking agent and use thereof

An anti-cracking agent, watermelon technology, applied in the application, biocide, pest control and other directions, can solve the problems of unable to meet the normal production of watermelon, the effect is not obvious, the control effect is weak, etc., to increase the immune function of the plant and improve the drought resistance performance. , the effect of normal growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

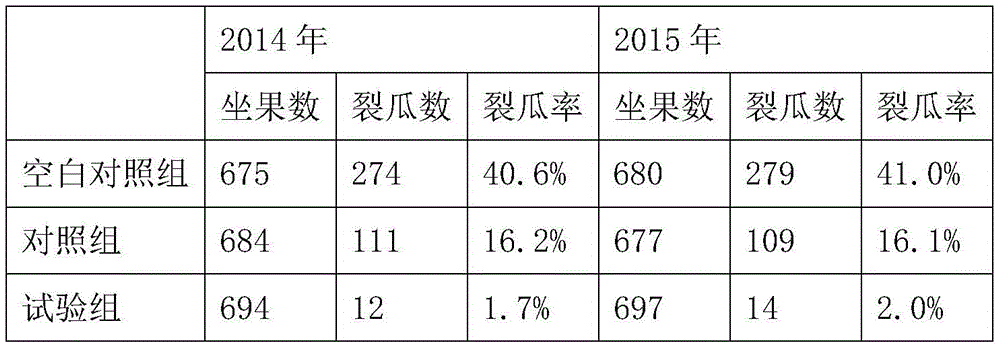

Image

Examples

Embodiment 1

[0024] Embodiment 1 prepares and applies watermelon anti-cracking agent

[0025] The composition of raw materials is: 10 grams of chitosan oligosaccharide, 10 grams of polyvinyl alcohol, 15 grams of methyl cellulose, 0.5 grams of brassinolide, 15 grams of dodecanoic acid, 20 grams of hexadecanoic acid, 10 grams of magnesium sulfate, 10 grams of calcium nitrate, 1.5 grams of borax, 5 grams of organic silicon, 2 grams of ammonium molybdate, and 1 gram of rare earth fertilizer.

[0026] The preparation method is:

[0027] (1) Dodecanoic acid and hexadecanoic acid are added in the water of 30 times of amount (weight multiple), add the sodium hydroxide (the molar sum of dodecanoic acid and hexadecanoic acid) of equimolar quantity, react 1 hour, to form a high lipid film, set aside;

[0028] (2) Add polyvinyl alcohol and methyl cellulose to 55 times the amount (weight multiple) of water, raise the temperature to 90°C, keep warm for 2 hours (so that the polyvinyl alcohol and methyl...

Embodiment 2

[0035] Embodiment 2 prepares watermelon anticracking agent

[0036] The composition of raw materials is: 5 grams of chitosan oligosaccharide, 10 grams of polyvinyl alcohol, 10 grams of methyl cellulose, 2 grams of brassinolide, 20 grams of dodecanoic acid, 15 grams of hexadecanoic acid, 5 grams of magnesium sulfate, 20 grams of calcium nitrate, 2 grams of borax, 3 grams of organic silicon, 1 gram of ammonium molybdate, and 2 grams of rare earth fertilizer.

[0037] Others are with embodiment 1.

Embodiment 3

[0038] Embodiment 3 prepares watermelon anticracking agent

[0039]The composition of raw materials is: 10 grams of chitosan oligosaccharide, 15 grams of polyvinyl alcohol, 20 grams of methyl cellulose, 1 gram of brassinolide, 40 grams of hexadecanoic acid, 5 grams of magnesium sulfate, 20 grams of calcium nitrate, 3 grams of borax gram, organic silicon 2 grams, ammonium molybdate 1 gram, rare earth fertilizer 1 gram.

[0040] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com