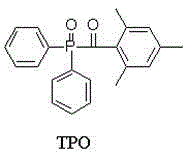

Preparation method of 2,4,6-trimethylbenzoyldiphenyl phosphine oxide

A technology of trimethylbenzoyldiphenyl and triphenylphosphine, which is applied in the field of preparation of 2,4,6-trimethylbenzoyldiphenylphosphine oxide, can solve the problem of large-scale production difficulty, High equipment requirements, difficult recycling and other issues, to achieve the effect of easy industrialization, simple operation and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 12

[0032] Example 12 Preparation method of 4,6-trimethylbenzoyl diphenyl phosphine oxide

[0033] 1) Under the protection of nitrogen, suspend the metallic sodium block (6.9g, 0.3mol) in 80ml of toluene, heat until refluxing, stir vigorously to form a powdered sodium suspension, add triphenylphosphine dropwise under vigorous stirring (26.2g, 0.1mol), after dripping, heat and reflux to react. When the triphenylphosphine reaction is complete, cool to room temperature, add phosphorus trichloride (6.9g, 0.05mol) dropwise, stir vigorously during the dripping process. , After dripping, heat to 100℃ to keep the reaction, TLC monitors the reaction;

[0034] 2) Cool the mixture obtained in step 1) to 80°C, add 2,4,6-trimethylbenzoyl chloride (27.4g, 0.15mol) dropwise at this temperature, drop the reaction, keep the reaction warm, and after the reaction is complete , Add water to the reaction system, stir and react for 0.5h;

[0035] 3) Add 30% hydrogen peroxide (51.0g, 0.45mol) to the reaction...

Embodiment 22

[0036] Example 22 Preparation method of 4,6-trimethylbenzoyl diphenyl phosphine oxide

[0037] 1) Under the protection of nitrogen, suspend the metal sodium block (6.9g, 0.3mol) in 80ml ethylbenzene, heat it until reflux, and stir vigorously to form a powdered sodium suspension, then add triphenylbenzene dropwise under vigorous stirring Phosphine (26.2g, 0.1mol), after dripping, heat to reflux for reaction, when the triphenylphosphine reaction is complete, cool to room temperature, add phosphorus trichloride (6.9g, 0.05mol) dropwise, stir vigorously during the dropping After the reaction, heat the reaction to 100°C after dropping, and monitor the reaction by TLC;

[0038] 2) Cool the mixture obtained in step 1) to 80°C, add 2,4,6-trimethylbenzoyl chloride (27.4g, 0.15mol) dropwise at this temperature, drop the reaction, keep the reaction warm, and after the reaction is complete , Add water to the reaction system, stir and react for 0.5h;

Embodiment 32

[0040] Example 32 Preparation method of 4,6-trimethylbenzoyl diphenyl phosphine oxide

[0041] 1) Under the protection of nitrogen, suspend the metallic sodium block (6.9g, 0.3mol) in 80ml of toluene, heat until refluxing, stir vigorously to form a powdered sodium suspension, add triphenylphosphine dropwise under vigorous stirring (26.2g, 0.1mol), after dripping, heat and reflux to react. When the triphenylphosphine reaction is complete, cool to room temperature, add phosphorus trichloride (6.9g, 0.05mol) dropwise, stir vigorously during the dripping process. , After dripping, heat to 100℃ to keep the reaction, TLC monitors the reaction;

[0042] 2) Cool the mixture obtained in step 1) to 80°C, add dropwise 2,4,6-trimethylbenzoyl chloride (31.1g, 0.17mol) at this temperature, drop the reaction, keep the reaction warm, and after the reaction is complete , Add water to the reaction system, stir and react for 0.5h;

[0043] 3) Add 30% hydrogen peroxide (51.0g, 0.45mol) to the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com