A monomer, a two-dimensional material and its preparation method and application

A two-dimensional material and monomer technology, applied in the preparation of carboxylate, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve problems such as lack of structural adjustability, and achieve low production cost, easy availability of raw materials, flexible internal effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

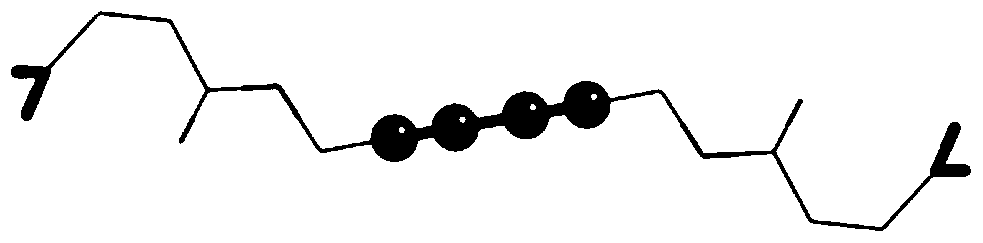

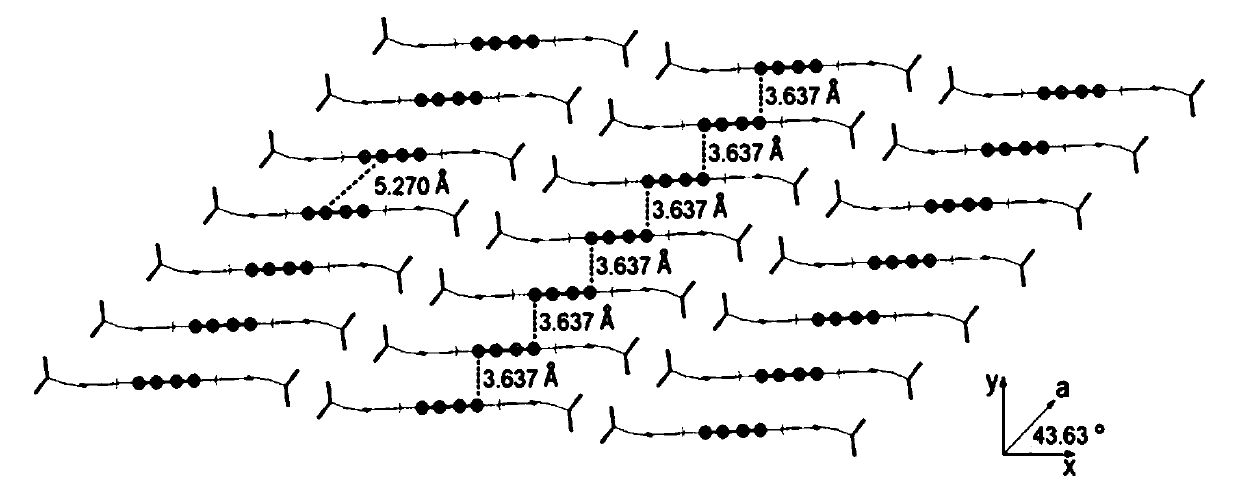

[0048] A kind of preparation method of monomer, its step is:

[0049] 1) Add 4.1g catalyst CuCl, 6.3mL tetramethylethylenediamine (TMEDA) and 50mL propynyl alcohol to the open reaction vessel A, heat the open reaction vessel A to 30°C (±10°C) while stirring the reaction The mixed system in the container, after the reaction is completed, add ether, and wash with saturated NH4Cl and NaCl solution to obtain a yellow organic solution, concentrate the organic solution to obtain a concentrated solution, then dissolve the concentrated solution in hot ethyl acetate, cool and crystallize , that is, 34.7 g of hexadiynediol was obtained, the yield was 73%, and the melting point was 112° C., which was consistent with the standard melting point. Bihexadiynediol is a known compound, and the synthetic steps are referenced in literature (W.R.Roush, M.L.Reilly, K.Koyama, B.B.Brown, J.Org.Chem. 1997, 62, 8708-8721).

[0050] 2) Weigh 2.25g of bihexadiynediol, add 2.25g of bihexadiynediol and 1...

Embodiment 2

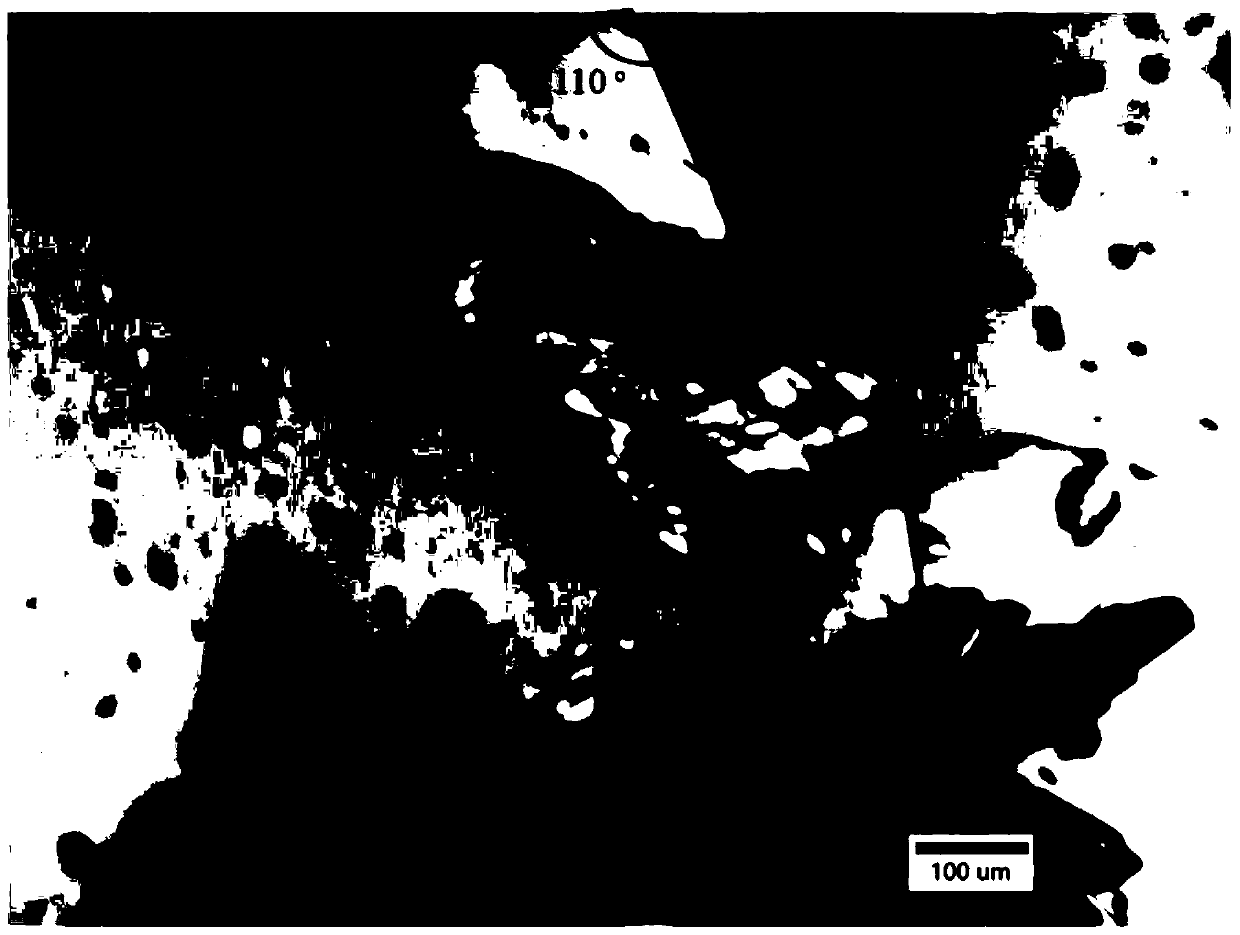

[0067] Taking the two-dimensional material (nanoscale thin film) prepared in Example 1 as an example to carry out the anti-electron beam bombardment test of the two-dimensional material, the use of the two-dimensional material is explained

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com