A kind of cold-sprayed aluminum-based corrosion-resistant coating and preparation method thereof

A cold spraying and coating technology, applied in the field of metal surface treatment, to achieve the effects of good wear resistance, low porosity and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

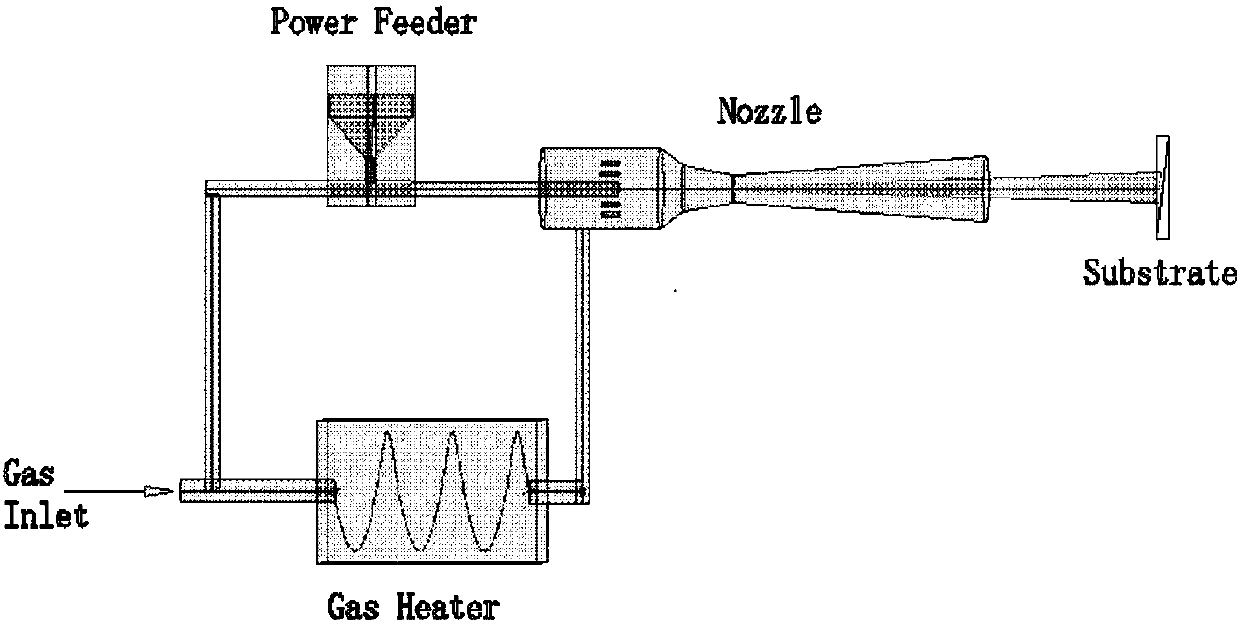

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of described cold-sprayed aluminum-based corrosion-resistant coating comprises the following steps:

[0034] (1) Choose Q235 carbon steel with a thickness of 3mm as the substrate, sandblast and degrease the surface, and then clean it with acetone and absolute ethanol ultrasonically. After cleaning and drying, seal it with a sample bag to avoid surface oxidation;

[0035] (2) Al (spherical particle size 10μm) and Al 2 o 3 The powder (with a particle size of 20 μm) was mixed mechanically, and the Al 2 o 3 The powder volume ratio is 30%; then add aluminum-magnesium alloy powder (particle size is 20 μm), mechanically mix evenly, the addition of aluminum-magnesium alloy powder accounts for 16.65% of the total mass, and the magnesium element accounts for 0.5% of the total mass, and the spray coating is obtained powder;

[0036] (3) Dry the spray powder obtained in step (2) in a vacuum oven at 90°C for 30 minutes;

[0037] (4) Turn on the cold spra...

Embodiment 2

[0040] The preparation method of described cold-sprayed aluminum-based corrosion-resistant coating comprises the following steps:

[0041] (1) Select A32 steel with a thickness of 4mm as the substrate, perform sandblasting and degreasing treatment on the surface, and then use acetone and absolute ethanol to clean it ultrasonically, and seal it with a sample bag after cleaning and drying to avoid surface oxidation ;

[0042] (2) Al (spherical particle size 20μm) and Al 2 o 3 The powder (particle size is 30 μm) is mechanically mixed, and the Al 2 o 3 The powder volume ratio is 30%; then add aluminum-magnesium alloy powder (particle size is 30 μm), mechanically mix evenly, the amount of aluminum-magnesium alloy powder added accounts for 6.5% of the total mass, and the magnesium element accounts for 0.2% of the total mass, and the spray coating is obtained powder;

[0043] (3) Dry the spray powder obtained in step (2) in a vacuum oven at 95°C for 28 minutes;

[0044] (4) Tur...

Embodiment 3

[0046] The preparation method of described cold-sprayed aluminum-based corrosion-resistant coating comprises the following steps:

[0047] (1) Choose Q235 carbon steel with a thickness of 3mm as the substrate, sandblast and degrease the surface, and then clean it with acetone and absolute ethanol ultrasonically. After cleaning and drying, seal it with a sample bag to avoid surface oxidation;

[0048] (2) Al (spherical particle size 30μm) and Al 2 o 3 The powder (with a particle size of 40 μm) was mixed mechanically, and the Al 2 o 3 The powder volume ratio is 30%; then add Al / RE powder (particle size is 10 μm), mechanically mix evenly, the addition of Al / RE powder accounts for 3.5% of the total mass, and the rare earth element accounts for 0.1% of the total mass, and the spray coating is obtained powder;

[0049] (3) Dry the spray powder obtained in step (2) for 35 minutes in a vacuum oven at 85°C;

[0050] (4) Turn on the cold spraying equipment, fix the substrate on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com