Method for preparing Gamma-Fe2O3 magnetic material by using abandoned toner cartridge

A magnetic material, -fe2o3 technology, applied in the direction of inorganic material magnetism, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of long production cycle, reduced production cost, high cost, low preparation cost and short production cycle , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A. Put the waste toner cartridge in the waste toner cartridge crushing magnetic separation device, and collect the black waste toner after crushing, magnetic separation, wind separation and other procedures;

[0020] B. Put the waste toner in a sieve, and sieve off the remaining inclusions to obtain a single organic toner;

[0021] C. Fully mix the organic toner and the organic solvent acetone at a mass ratio of 1:2, vibrate and centrifuge to obtain a black precipitate, and dry the precipitate at 60°C;

[0022] D. Subsequently, the dried precipitate is placed in a muffle furnace, calcined at 300°C for 4 hours, and cooled to room temperature to obtain γ-Fe 2 o 3 magnetic material;

[0023] E. At 55~60°C, the supernatant after centrifugation is distilled to recover acetone.

Embodiment 2

[0025] A. Put the waste toner cartridge in the waste toner cartridge crushing magnetic separation device, and collect the black waste toner after crushing, magnetic separation, wind separation and other procedures;

[0026] B. Put the waste toner in a sieve, and sieve off the remaining inclusions to obtain a single organic toner;

[0027] C. Fully mix the organic toner and the organic solvent ethyl acetate according to the mass ratio of 1:3, shake and centrifuge to obtain a black precipitate, and dry the precipitate at 70°C;

[0028] D. Subsequently, the dried precipitate is placed in a muffle furnace, calcined at a temperature of 400°C for 2 hours, and cooled to room temperature to obtain γ-Fe 2 o 3 magnetic material.

[0029] E. At 75~80°C, the supernatant after centrifugation is distilled to recover ethyl acetate.

Embodiment 3

[0031] A. Put the waste toner cartridge in the waste toner cartridge crushing magnetic separation device, and collect the black waste toner after crushing, magnetic separation, wind separation and other procedures;

[0032] B. Put the waste toner in a sieve, and sieve off the remaining inclusions to obtain a single organic toner;

[0033] C. Fully mix the organic toner and the organic solvent benzene according to the mass ratio of 1:5, shake and centrifuge to obtain a black precipitate, and dry the precipitate at 80°C;

[0034] D. Subsequently, the dried precipitate is placed in a muffle furnace, calcined at a temperature of 600°C for 1 hour, and cooled to room temperature to obtain γ-Fe 2 o 3 magnetic material.

[0035] E. At 78~82°C, the supernatant after centrifugation is distilled to recover benzene.

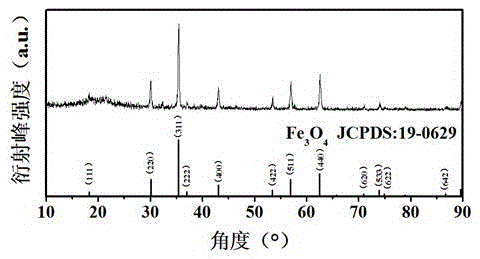

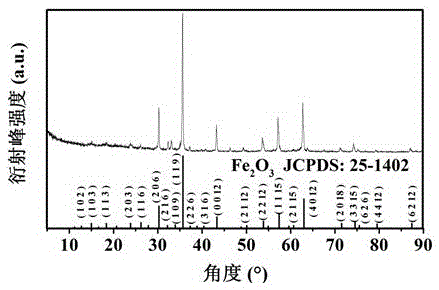

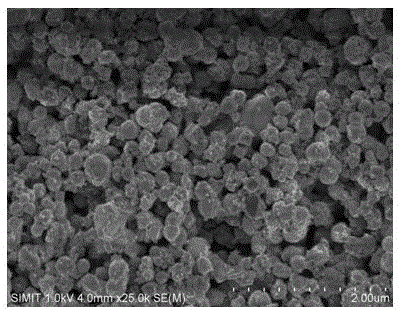

[0036] Using X-ray powder diffraction (XRD), scanning electron microscopy (SEM), vibrating sample magnetometer (VSM) and other characterization means to analyze the organ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Magnetic saturation | aaaaa | aaaaa |

| Magnetic saturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com