Crucible made from green oil coke and water-soluble adhesive and manufacturing method of crucible

A technology of water-soluble binder and petroleum coke, which is applied in the field of crucible manufacturing, can solve the problems of only effective utilization rate, high production cost, and energy consumption, and achieve the effects of saving land use area, labor cost, and capital

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

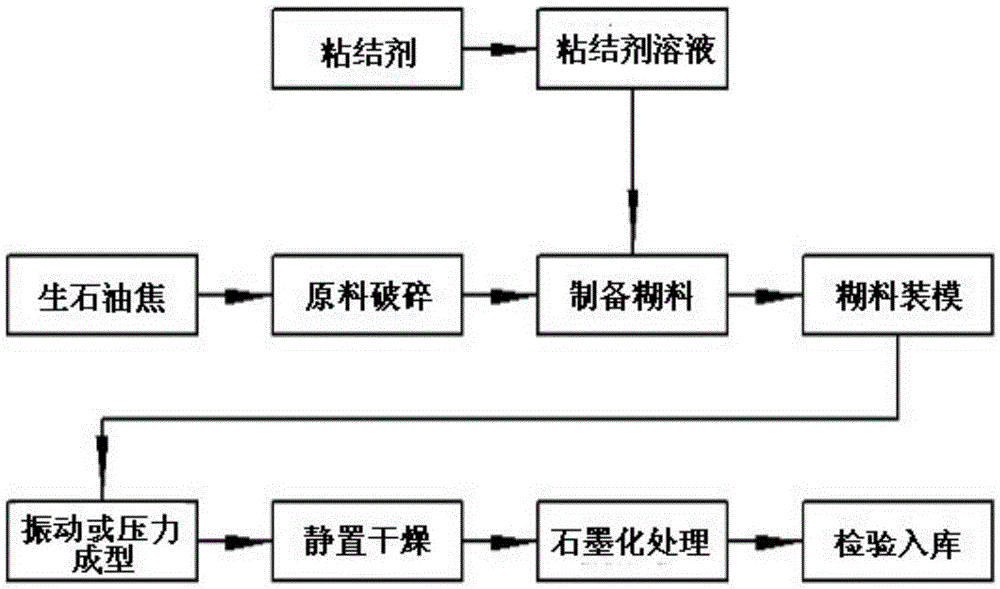

[0035] Process for making crucibles from raw petroleum coke and water-soluble binders, such as figure 1 shown, including the following steps:

[0036] Step 1, crushing raw petroleum coke until 100% passes through a 2mm sieve;

[0037] Step 2, mixing α-starch and purified water according to the mass ratio of 3:10 to make a binder solution;

[0038] Step 3. Mix the binder solution with the crushed raw petroleum coke in a certain proportion, and stir for 75 minutes to obtain a paste. The mass ratio of α-starch, purified water and raw petroleum coke in the paste is 3:10: 95;

[0039] Step 4. Quantitatively put the above-mentioned paste into the crucible mold, put the crucible mold with the paste into the vibration molding machine, vibrate for 18 minutes at a vibration frequency of 2950 times / min, and the amplitude is 1.2mm. After mechanical vibration molding, the crucible The density of the wet embryo is 1.5g / cm3;

[0040] Step 5. Take out the formed wet crucible embryo and le...

Embodiment 2

[0044] Process for making crucibles from raw petroleum coke and water-soluble binders, such as figure 1 shown, including the following steps:

[0045]Step 1, crushing the raw petroleum coke until 100% is less than 3mm;

[0046] Step 2, soluble chitosan and deionized water are mixed according to the mass ratio of 6:18 to make binder solution, and above-mentioned soluble chitosan is the water-soluble chitosan that chitosan is made through carboxylation modification;

[0047] Step 3, mixing the binder solution with the crushed raw petroleum coke in a certain proportion, stirring for 125 minutes to obtain a paste, the mass ratio of soluble chitosan, deionized water and raw petroleum coke in the paste is 6: 18:100;

[0048] Step 4, quantitatively put the above-mentioned paste into the crucible mold, put the crucible mold with the paste into the pressure forming machine, press for 18 minutes under the pressure of 4KPa to obtain the wet crucible embryo;

[0049] Step 5. Take out t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com