A kind of preparation method of 4,4-dichlorodiphenyl sulfone

A technology of dichlorodiphenyl sulfone and chlorobenzene, which is applied in the field of chemical material preparation, can solve the problems of complicated reaction steps, poor product quality stability, three wastes of easily corroded equipment, etc., and achieves low comprehensive cost, short reaction period, three wastes and the like. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Add 30Kg of dimethyl sulfoxide as a catalyst in a clean enamel kettle, add 598Kg of liquid sulfur trioxide and 470Kg of dimethyl sulfate, and esterify at 20°C for 2.5h to obtain 1098Kg of esterification material;

[0048] (2) Take a clean enamel kettle, add 837Kg of chlorobenzene, and add the esterified material obtained in step (1) to the chlorobenzene at 2800mL / min while maintaining the temperature at 25℃, and keep the temperature for 3h to obtain the condensation material ;

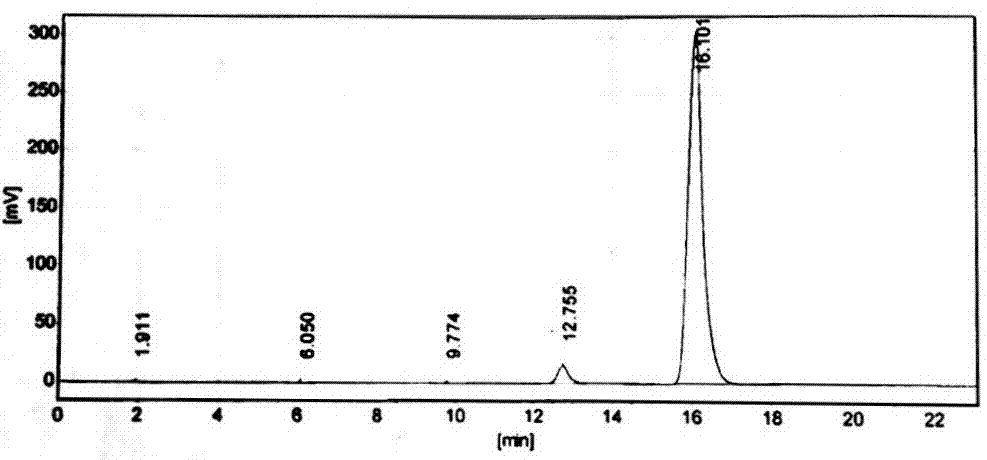

[0049] (3) Take another clean enamel kettle and add 534Kg of sodium hydroxide and 2432Kg of water. After fully dissolving, heat the condensate obtained in step (2) to 60°C, and slowly add dropwise to the sodium hydroxide at 7400mL / min Hydrolyzed in aqueous solution (mass percentage concentration of 18%), heated to 80°C, stirred, refluxed for 1h, cooled to 60°C, centrifuged at 3500r / min for 60min, took the filter cake and washed it with 60°C hot water to neutral (pH value 7.0), 998.7Kg of 4,4-di...

Embodiment 2

[0051] (1) Add 30.5Kg of dimethyl sulfoxide as a catalyst in a clean enamel kettle, add 611Kg of liquid sulfur trioxide and 480Kg of dimethyl sulfate, and esterify at 16℃ for 3h to obtain 1121.5Kg of Esterified material

[0052] (2) Take a clean enamel kettle, add 855Kg of chlorobenzene, and add the esterified material obtained in step (1) to the chlorobenzene at 2800mL / min while keeping the temperature at 30℃, and keep the temperature for 1h to obtain the condensation material ,

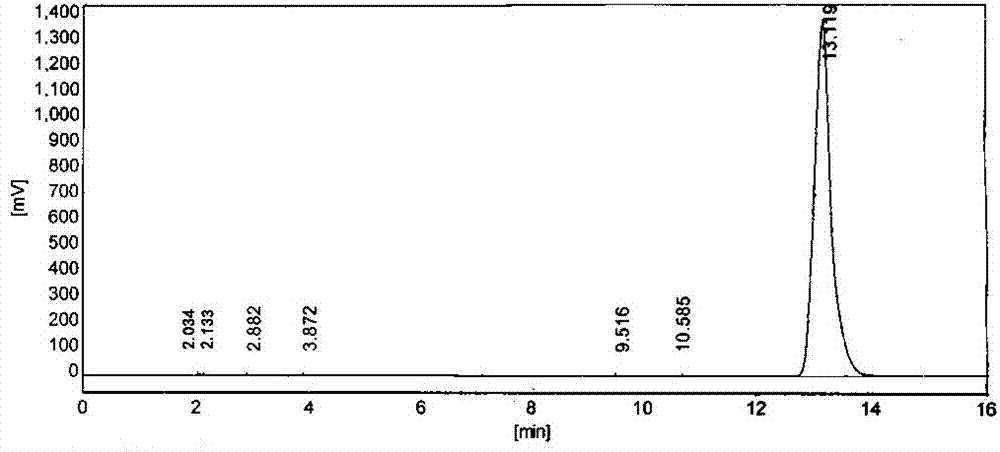

[0053] (3) Take another clean enamel kettle, add 545Kg of sodium hydroxide, add 2483Kg of water, and after fully dissolving, heat the condensate obtained in step (2) to 55℃, and slowly add dropwise to the sodium hydroxide at 7400mL / min Hydrolyzed in an aqueous solution (18% by mass), heated to 70°C, stirred, refluxed for 1h, cooled to 60°C, 3500r / min), centrifuged for 65min, and washed the filter cake with hot water at 75°C to neutral (pH value 7.0) to obtain 998.5Kg of 4,4-dichlorodiphenylsulfone.

Embodiment 3

[0055] (1) Add 30.3Kg of dimethyl sulfoxide as a catalyst in a clean enamel kettle, add 606Kg of liquid sulfur trioxide and 476Kg of dimethyl sulfate, and esterify at 10℃ for 3h to obtain 1112.3Kg of Esterified material

[0056] (2) Take a clean enamel kettle, add 848Kg of chlorobenzene, and add the esterified material obtained in step (1) to the chlorobenzene at 2800mL / min while keeping the temperature at 30℃, and keep the temperature for 1 hour to obtain the condensation material ,

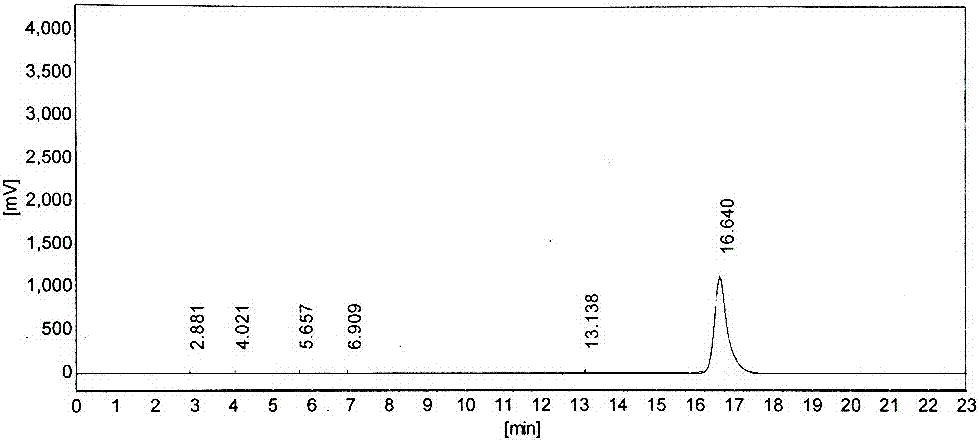

[0057] (3) Take another clean enamel kettle and add 541Kg of sodium hydroxide and 2465Kg of water. After fully dissolving, heat the condensate obtained in step (2) to 50°C, and slowly add dropwise to the sodium hydroxide at 7400mL / min Hydrolyzed in an aqueous solution (18% by mass), heated to 70°C, stirred, refluxed for 1.5h, cooled to 60°C, centrifuged at 3500r / min for 60min, and the filter cake was washed with 70°C hot water to neutral (pH value 7.0), 998.8Kg of 4,4-dichlorodiphenylsulfone was ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com