Catalyst component used for ethylene homopolymerization or copolymerization reaction, and catalyst thereof

A technology of ethylene polymerization and catalyst, which is applied in the field of catalyst preparation, and can solve problems such as the inability to achieve precise control and the inability to prepare polyethylene powder particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

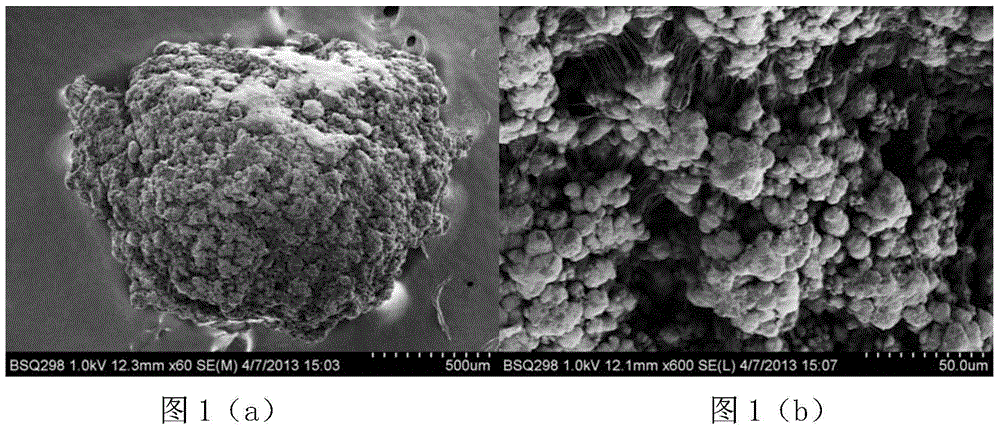

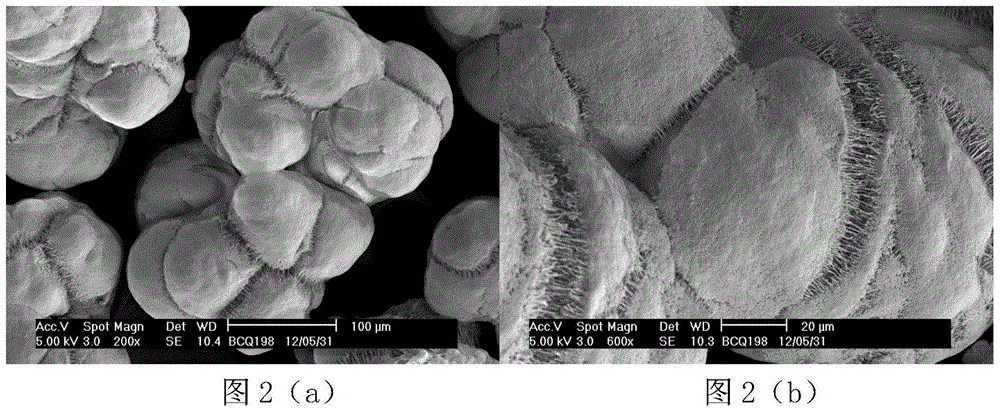

Image

Examples

Embodiment 1

[0058] (1) Preparation of catalyst components

[0059] Add 4.0 g of magnesium chloride, 100 ml of toluene, 8.0 ml of epichlorohydrin, and 15 ml of tri-n-butyl phosphate into the reaction kettle, and react for 2 hours at a stirring speed of 450 rpm and a temperature of 60°C, and add 2 g of phthalate Formic anhydride, 2ml butyl acetate and 100mg polyepichlorohydrin (Mn=16000), continue to keep the temperature constant for 1 hour, cool down to -40°C, add 70ml of titanium tetrachloride dropwise, gradually heat up to 95°C, hold the temperature for 1 hour, filter Remove the mother liquor, wash with inert diluent toluene and organic solvent hexane several times, and then dry to obtain a solid containing magnesium / titanium.

[0060] (2) Polymerization reaction:

[0061] A stainless steel reaction kettle with a capacity of 2L, after being fully replaced by high-purity nitrogen, was added with 1L of hexane and 1.0ml of a 1M triethylaluminum / hexane solution, and then added the solid cat...

Embodiment 2

[0064] (1) Preparation of catalyst components

[0065] Add 4.0 grams of magnesium chloride, 120 ml of toluene, 9.0 ml of epichlorohydrin, and 19 ml of tri-n-butyl phosphate into the reaction kettle, and react for 2 hours at a stirring speed of 450 rpm and a temperature of 60°C, and add 3 grams of phthalate Formic anhydride, 1ml butyl acetate and 150mg polymethyl methacrylate (Mn=20000), continue to keep the temperature constant for 1 hour, cool down to -40°C, add 30ml of titanium tetrachloride dropwise, gradually raise the temperature to 95°C, keep the temperature for 1 hour, The mother liquor was filtered off, washed several times with inert diluent toluene and organic solvent hexane, and then dried to obtain a solid containing magnesium / titanium.

[0066] (2) Polymerization reaction: with embodiment 1, polymerization result is shown in Table 1.

Embodiment 3

[0068] (1) Preparation of catalyst components

[0069] Add 4.0 grams of magnesium chloride, 160ml of toluene, 10ml of epichlorohydrin, and 18ml of triisobutyl phosphate into the reaction kettle, and react for 2 hours at a stirring speed of 350rpm and a temperature of 60°C, and add 3 grams of phthalo Acid anhydride, 1ml of n-octyl acetate and 210mg of polyethylene glycol (Mn=6000), continue to keep the temperature constant for 1 hour, cool down to -45°C, add 30ml of titanium tetrachloride dropwise, gradually raise the temperature to 95°C, hold the temperature for 1 hour, filter off The mother liquor is washed several times with the inert diluent toluene and the organic solvent hexane, and then dried to obtain a solid containing magnesium / titanium.

[0070] (2) Polymerization reaction: with embodiment 1, polymerization result is shown in Table 1.

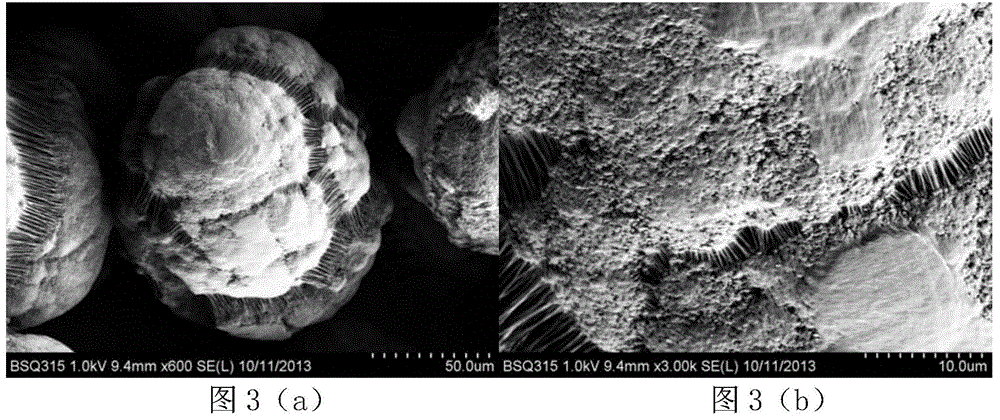

[0071] (3) Electron microscope photo: See Figure 3 for the electron microscope photo of the powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com