UV waterless offset print light disk black printing ink and preparation method thereof

A waterless offset printing and optical disc technology, applied in inks, household appliances, applications, etc., can solve the problems of poor smudge resistance, poor rheological properties and ink transfer properties, and achieve excellent rheological properties and ink transfer properties. The effect of good dirt pick-up and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

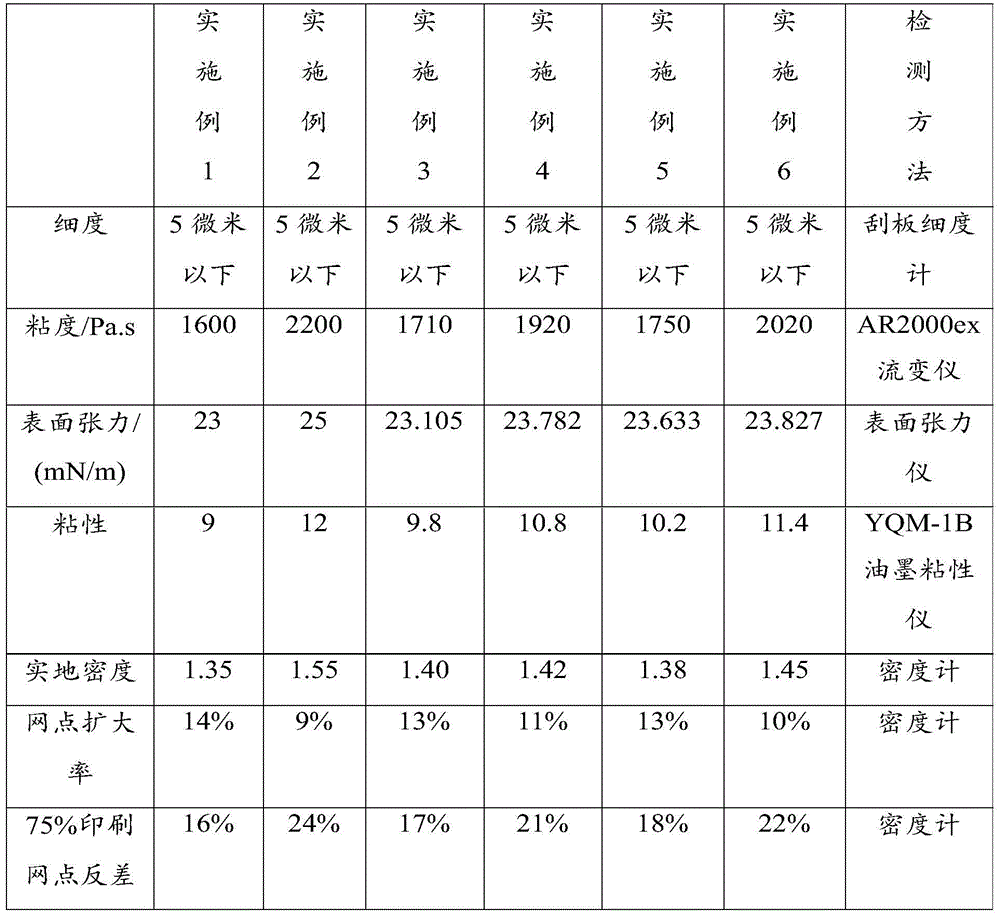

Examples

Embodiment 1

[0041] In parts by weight, take by weighing 12 parts of black pigment, 1 part of phthalocyanine blue pigment, 35 parts of polyester acrylate, 8 parts of ethoxy ethoxy ethyl acrylate (EOEOEA), 6 parts Parts of 2,4-diethylthioxanthone, 5 parts of fumed silica, 1.5 parts of silicone acrylate, 1 part of polyoxyethylene alkylphenol ether, 0.01 part of glycerol monostearate ester, 1 part of phosphate methacrylate monomer, and then mix the above-mentioned raw material components, and pre-disperse them on a glass plate, and then grind them with a three-roll mill until the pigments are evenly dispersed. During the grinding process, adjust the three The gap between the rollers of the roller grinder, and the fineness of the ink is tracked and tested until the fineness of the ink reaches about 5 microns, and the grinding is stopped to obtain the finished product.

Embodiment 2

[0043] In parts by weight, use a balance to weigh 18 parts of black pigment, 2 parts of phthalocyanine blue pigment, 55 parts of epoxy acrylate and polyether acrylate (the ratio of parts by weight of the two is 1:1) to form Prepolymer, 18 parts of tripropylene glycol dipropylene ester (TPGDA) and dipropylene glycol diacrylate (DPGDA) (the weight ratio of the two is 1:1) monomers, 10 parts of 2 -Hydroxy-2-methyl-1-phenyl-1-propanone, 16 parts of kaolin, 2.5 parts of silicone acrylate, 2 parts of polyoxyethylene fatty alcohol ether, 0.1 part of sucrose ester, 3 parts of Silane coupling agent, then mix the above-mentioned raw material components, and pre-disperse on the glass plate, and then grind with a three-roll mill until the pigment is evenly dispersed. And the fineness of the ink is tracked and tested until the fineness of the ink reaches about 5 microns, and the grinding is stopped to obtain the finished product.

Embodiment 3

[0045] In parts by weight, take 14 parts of black pigment with a balance, 1.5 parts of phthalocyanine blue pigment, 50 parts of polyester acrylate, polyurethane acrylate (the ratio of the two parts by weight is 1:1) A prepolymer consisting of 12 parts of ethoxylated trimethylolpropane triacrylate (EO3-TMPTA) and propoxylated trimethylolpropane triacrylate (PO3-TMPTA) (both by weight The ratio of parts is 1:1) composed of monomers, 8 parts of 2-ethylhexyl acrylate, 8 parts of talc, 2 parts of silicone acrylate, 1 part of polyoxyethylene-polyoxypropylene Block copolymer, 0.05 parts of sorbitan fatty acid, 1.5 parts of phosphorus methacrylate monomer, then the above-mentioned raw material components are mixed, and pre-dispersed on a glass plate, and then ground with a three-roll mill until The pigment is dispersed evenly. During the grinding process, adjust the nip gap of the three-roll mill in good time, and track and test the fineness of the ink until the fineness of the ink re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| tackiness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com