Production method of novel organic rectorite for oil-based drilling fluid

A technology of oil-based drilling fluid and production method, applied in the direction of chemical instruments and methods, drilling composition, etc., can solve the problems of increased drill pipe torque, affecting product performance, and increased fluid loss, etc., reaching a strong market Competitiveness, low material cost, high competitiveness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

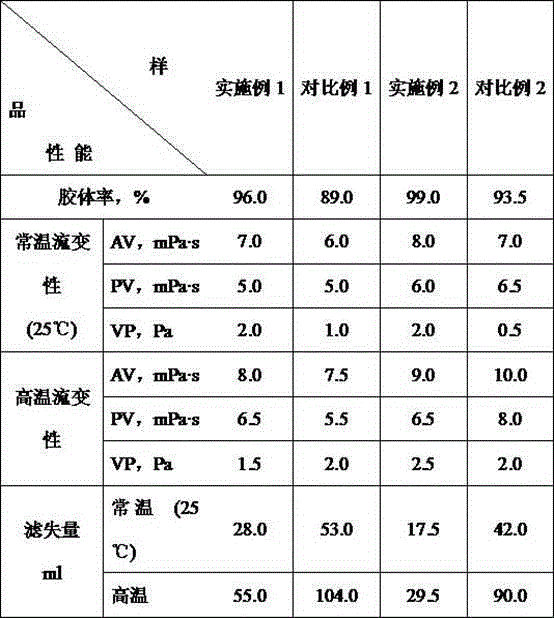

Examples

Embodiment 1

[0026]In the reaction vessel, add 100 parts of calcium-based rectorite powder (100 mesh) with a purity of 66% and a water content of 6%, add a mixed solution of 2 parts of sodium carbonate, 1.5 parts of lithium carbonate, and 200 parts of water, and then add 200 parts of Industrial water, heated and stirred at a speed of 120rpm, the temperature was raised to 90°C. Keep stirring for 45 minutes, take 20 parts of cetyltrimethylammonium chloride with a net content of 75% (the rest is mainly water), add it to the container, keep the temperature of the container at 90°C, continue to stir at a speed of 120rpm, and organically React for 90 minutes. Add 200 parts of industrial water at room temperature and stir for 2 minutes to adjust the dilution ratio of the slurry. Subsequently, the slurry is introduced into a vacuum filter for suction filtration, the filter cake is taken out, placed in a cool place for 24 hours, and dried to a water content of 3%. Pulverized to 200 mesh (0.074mm)...

Embodiment 2

[0030] In a sealable reaction vessel, add 100 parts of calcium-based rectorite powder with a purity of 73% and a water content of 6.5%, a mixed solution of 3 parts of sodium carbonate, 2 parts of lithium oxalate, and 200 parts of water, and then add 300 parts of industrial With water, heat and stir at 120 rpm, raise the temperature to 80°C. Keep stirring for 45 minutes, take 28.5 parts of octadecyldimethylbenzyl ammonium chloride with a net content of 75% (the rest is mainly water), add it to the container, keep the temperature of the container at 115 °C and build up the pressure in the closed container, Continue to stir at a speed of 120rpm and keep warm for 60 minutes. Subsequently, the slurry is introduced into a vacuum filter for suction filtration. When about 80% of the filtrate is discharged and the concentration of the remaining slurry in the suction filter funnel increases significantly, add 400 parts of industrial water, and then filter again to dry the water. Take o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com