Enclosed petroleum coke dehydration degassing transportation system and method

A dehydration, degassing, closed technology, applied in the petroleum industry, cracking, non-catalytic thermal cracking, etc., can solve the problems of high labor costs, clogging of decoking equipment, and high equipment investment costs, achieve no harmful gas volatilization, and improve automation. level, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

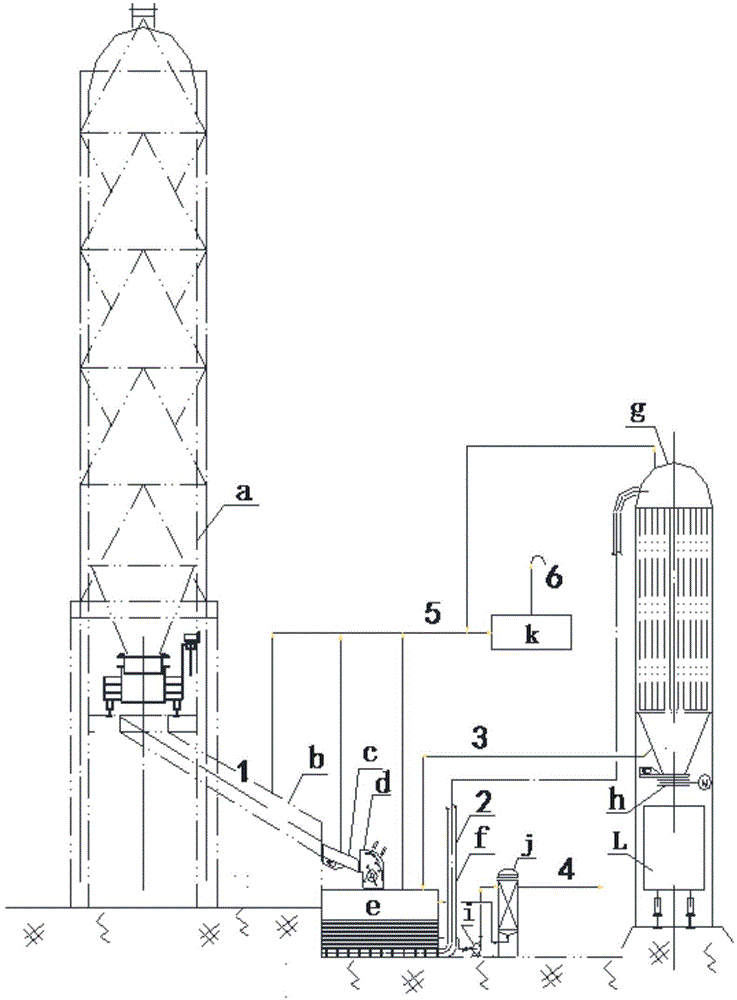

[0034] Such as figure 1 Shown, a closed petroleum coke dehydration and degassing transport system. Including: coke chute b, vibrating screen c, crusher d, filter tank e, tube conveyor f, water separation silo g, vibrating feeder h, coke cutting water lift pump i, coke cutting water filter j and tail gas treatment unit k;

[0035] The coke chute b is a tubular structure, one end is connected to the bottom outlet of the coke tower a, and one end is connected to the vibrating screen c and the crusher d in sequence; the filter pool e is located below the vibrating screen c and the crusher d, and the outlet of the crusher d is connected to the filter pool e At the top, a tube conveyor f is set at the bottom of the filter pool e, and the other end of the tube conveyor f is connected to the upper part of the water distribution silo g; the middle of the filter pool e is connected to the coke cut water lift pump i and the coke cut water filter j in sequence, and coke cut The bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com