Alkyl pyridinium quaternary ammonium salt corrosion inhibitor used for inhibiting carbon dioxide corrosion and preparation method thereof

An alkylpyridine and carbon dioxide technology, applied in the field of metal corrosion and protection, can solve the problems of poor temperature resistance, general effect, high cost and the like, and achieve the effects of low cost, no three waste pollution, and simple route.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

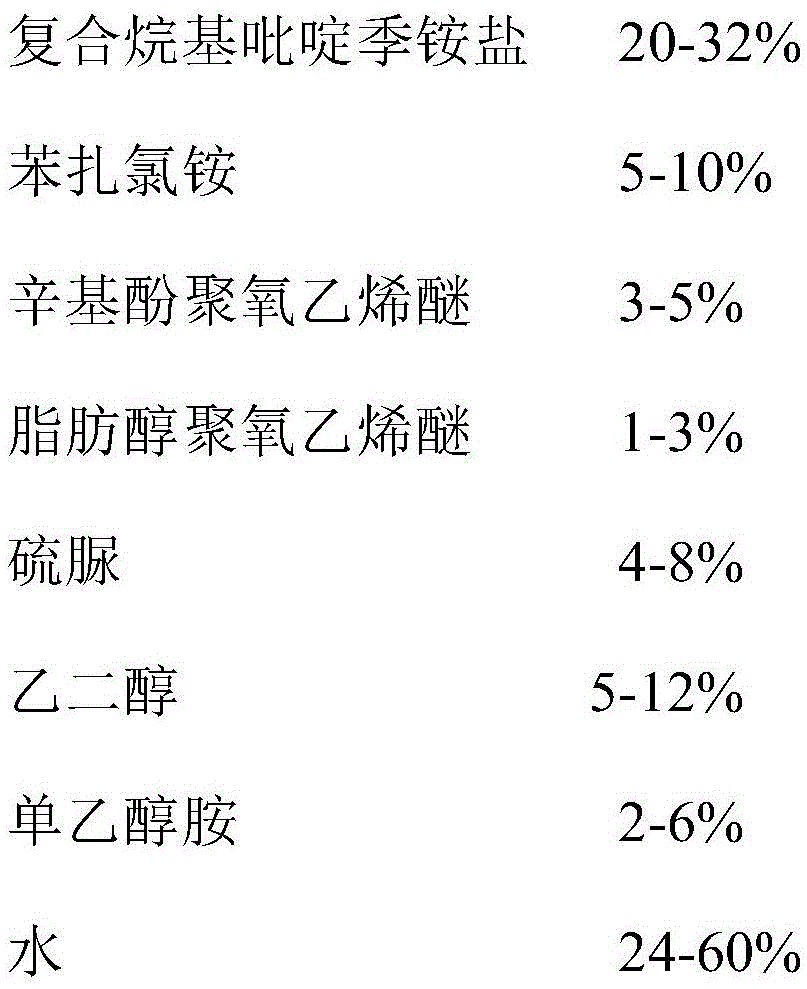

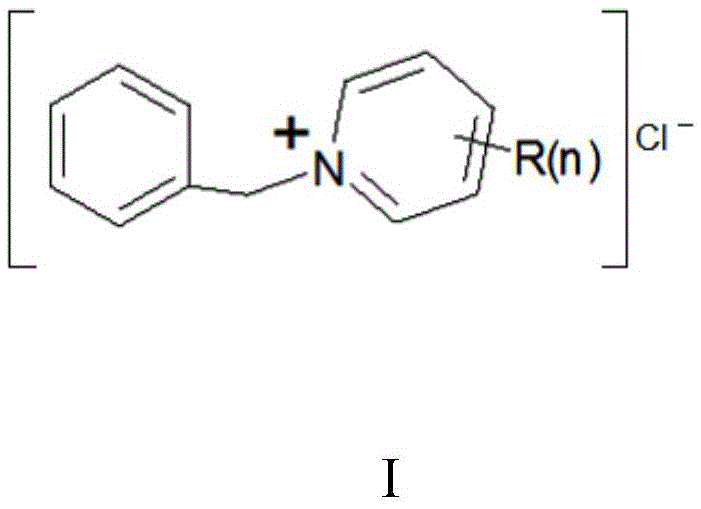

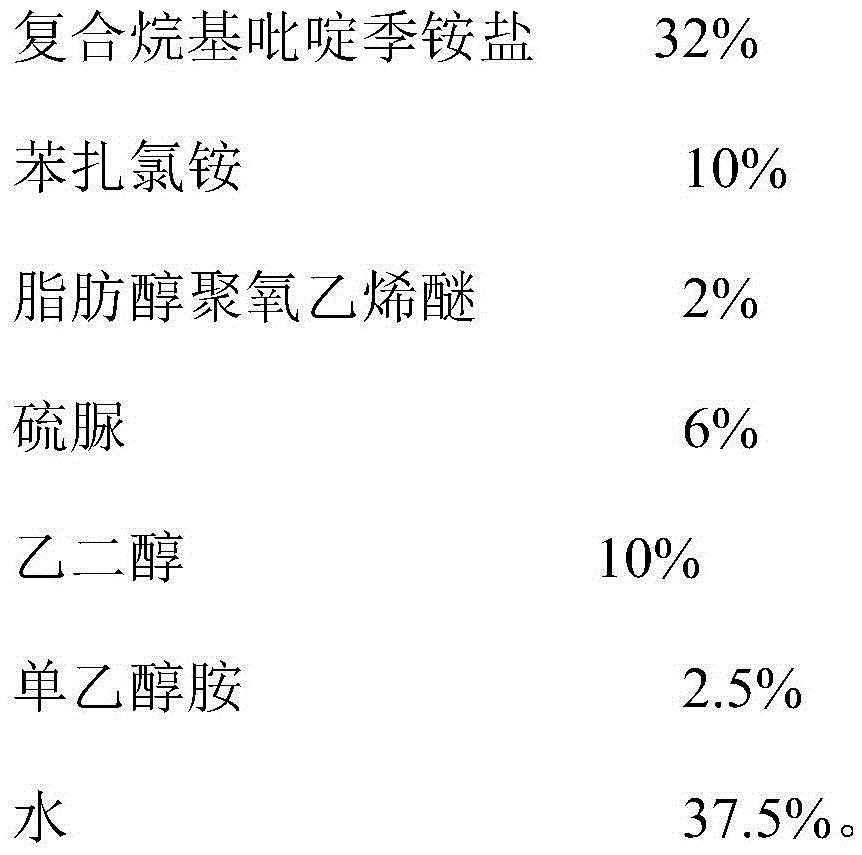

[0029] This embodiment is used to prepare alkylpyridinium quaternary ammonium salt

[0030]

[0031] Wherein, R is H or methyl, and n is 1, 2 or 3.

[0032] The above structural formula is an alkylpyridine, and the composite alkylpyridine used in this embodiment is a combination of all the alkylpyridines listed in the above structural formula.

[0033] Put 180g of compound alkylpyridine and 22g of DMF into the reactor, heat up to 80°C under reflux condensation, start to add 120g of benzyl chloride dropwise, and control the temperature. hour, the temperature was lowered to 100° C., and 78 g of methanol was added dropwise to obtain 400 g of brown complex alkylpyridinium quaternary ammonium salts.

Embodiment 2

[0035] This embodiment is used to prepare benzalkonium chloride

[0036] 220g of dodecylamine was put into the reactor, and the temperature was raised to 70°C. Under the condition of reflux condensation, 120g of benzyl chloride was added dropwise to control the temperature. After the dropwise addition, the temperature was raised to 88° C., the reaction was carried out for 5 hours, the temperature was lowered, and 95 g of a mixed solution of methanol and water (mass ratio 1:1) was added.

Embodiment 3

[0038] This implementation case is used to prepare corrosive medium

[0039] 50gNaCL, 2gMgCL.6H 2 O, 6gNa 2 SO 4 , 4gCaCL 2 , 0.4gNaHCO 3 Add it into 1000g of water, stir to dissolve it completely, and obtain a 5.8% saline solution as a corrosion medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com