Amidoximated polyacrylonitrile spinning solution and nanoscale ion exchange fiber prepared from solution

A technology of polyacrylonitrile spinning and ion exchange fiber, applied in cation exchange materials, ion exchange water/sewage treatment, rayon manufacturing, etc., can solve the problems of easy breakage, complicated process, difficult spinning, etc., and achieve excellent adsorption performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of amidoximated polyacrylonitrile solution: adding 2.9g hydroxylamine hydrochloride and 6.9g potassium carbonate to the DMF solution of 40g polyacrylonitrile (Jilin Petrochemical Company) with a mass percent concentration of 10.0%, heating and stirring at 80°C, After reacting for 3.5 hours, stop heating and cool to room temperature, and filter to obtain an amidoximated polyacrylonitrile solution.

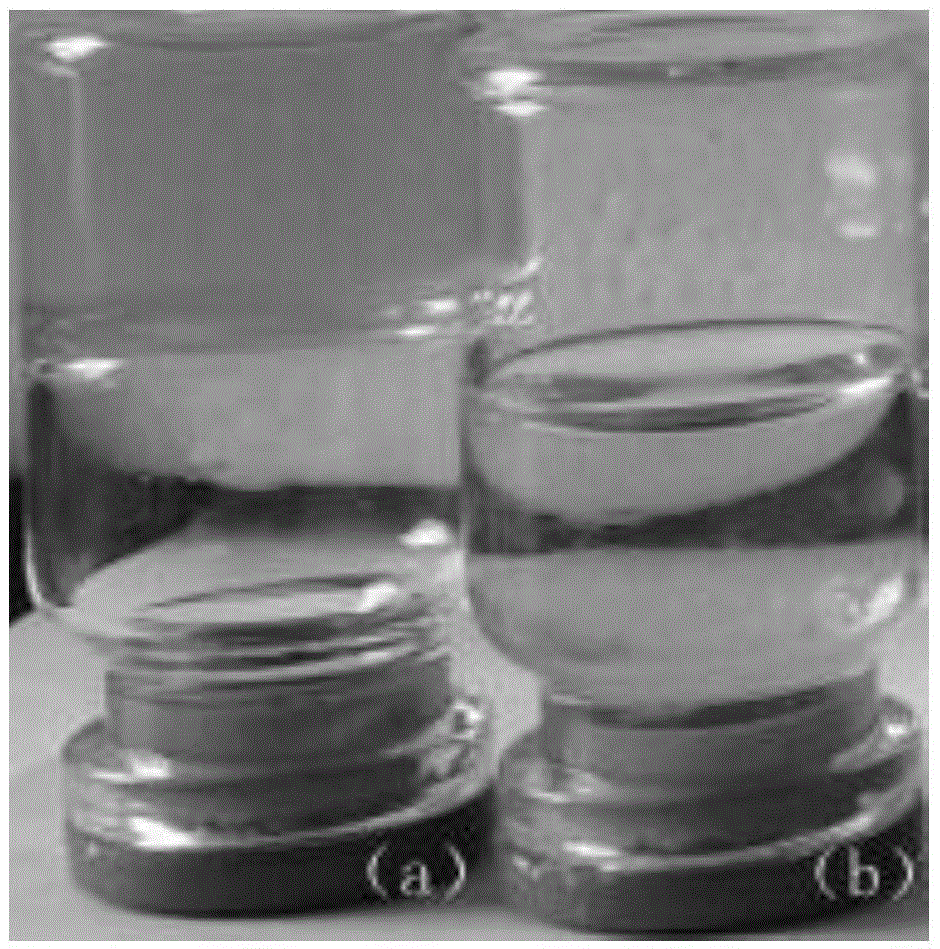

[0033](2) Viscosity change: Use a rotary viscometer to measure the viscosity of the amidoximated polyacrylonitrile solution obtained in step (1). During the measurement, it is found that with the rotation of the viscometer rotor, the pointer on the reading dial begins to shake significantly, and the viscosity increases in a short time. Movement in the general direction, beyond the range of the viscometer. After rotating for a few minutes, the amidoximated polyacrylonitrile solution has been cross-linked, and the formed cross-linked product adheres to the surfa...

Embodiment 2-4

[0036] Add 2.9g of hydroxylamine hydrochloride and 6.9g of potassium carbonate to a DMF solution of 40g of polyacrylonitrile with a concentration of 10.0% by mass, heat and stir at 80°C, react for 3.5h, stop heating and cool to room temperature, and filter to obtain amidoximated polypropylene Nitrile solution.

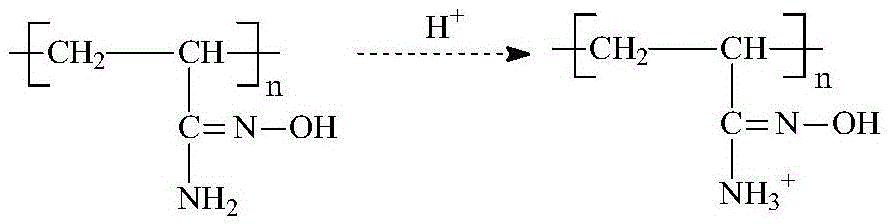

[0037] Add formic acid to the prepared amidoximated polyacrylonitrile solution as a cross-linking inhibitor, stir at room temperature for 3.5 hours to obtain amidoximated polyacrylonitrile spinning solution, measure the solution after standing at room temperature for 0h, 12h, 24h, 36h, and 72h viscosity.

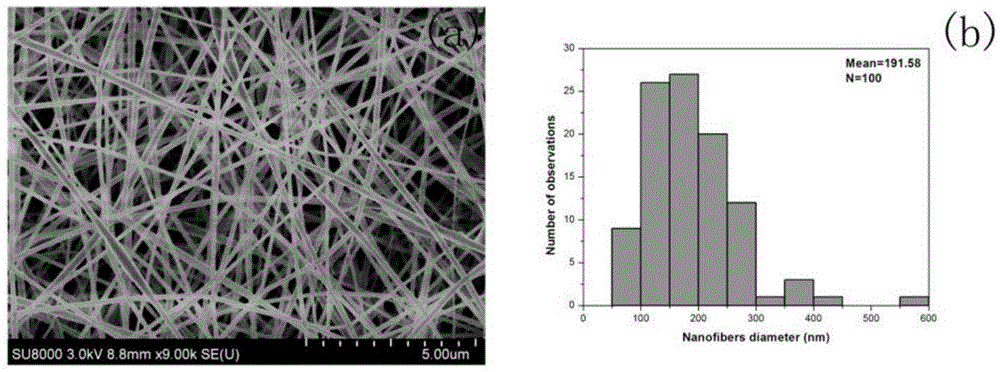

[0038] Using the above-mentioned amidoximated polyacrylonitrile spinning solution as raw material, using electrospinning technology (Zhao Yiyang, high-voltage electrospinning technology to construct one-dimensional micro-nano structure materials [Ph. Under the condition of 20%, the spinning voltage is adjusted to 18KV, the receiving distance is 15cm, the advancing s...

Embodiment 5-7

[0040] Add 2.9g of hydroxylamine hydrochloride and 6.9g of potassium carbonate to a DMF solution of 40g of polyacrylonitrile with a concentration of 10.0% by mass, heat and stir at 80°C, react for 3.5h, stop heating and cool to room temperature, and filter to obtain amidoximated polypropylene Nitrile solution.

[0041] Add quantitative acetic acid to the prepared amidoximated polyacrylonitrile solution as a cross-linking inhibitor, stir at room temperature for 3-4 hours to obtain amidoximated polyacrylonitrile spinning solution, and place them at room temperature for 0h, 12h, 24h, 36h, and 72h respectively Measure the solution viscosity.

[0042] According to the method in Example 2, amidoximated polyacrylonitrile nanofibers were prepared, and their adsorption capacity for copper ions and lead ions was determined.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com