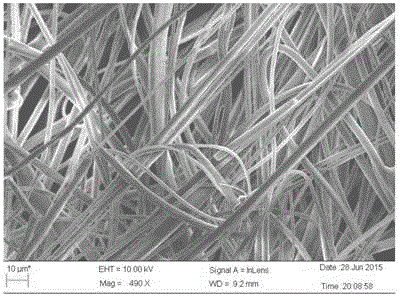

Thermocured electrospun egg-white protein micro-nanofiber membrane and preparation method therefor

A technology of micro-nano fiber and egg white protein, which is applied in the field of heat-cured electrospun egg white protein micro-nano fiber membrane and its preparation, can solve the problems of stimulating skin allergic reaction, corrosive and irritating, harmful to human body and environment, and achieves Good biocompatibility and degradability, simple preparation method, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

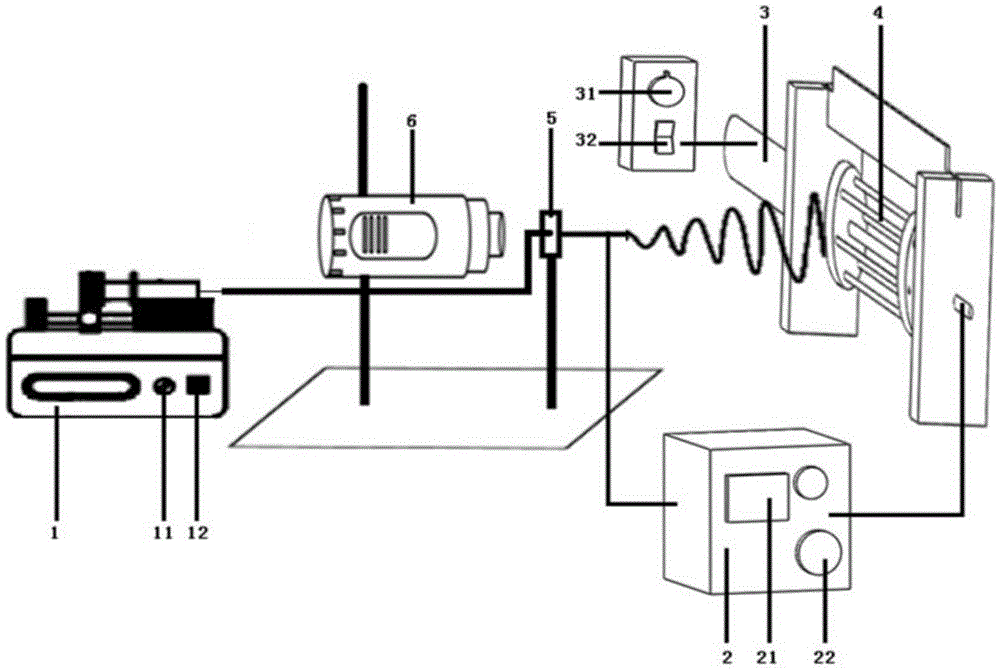

[0030] A method for preparing a heat-cured electrospun egg white protein micro-nano fiber membrane, comprising the following steps:

[0031] (1) Configure the spinning precursor solution: add 0.15 grams of polyethylene oxide (PEO, AldrichChemistry) in the Erlenmeyer flask, then add 5 grams of deionized water, stir with a magnetic stirrer, and stir for 1 hour at room temperature to make Polyethylene oxide is fully dissolved and prepared as solution A. Add 5 grams of fresh egg white into the conical flask containing the prepared solution A, stir with a magnetic stirrer to fully dissolve solution A and egg white, and prepare the spinning precursor liquid;

[0032] (2) Electrospun fiber: Inhale the prepared precursor solution into a 5 ml syringe and fix it on the propulsion pump 1. The flow of the spinning precursor solution is controlled by the propulsion pump 1, and the propulsion pump is turned on. The propulsion rate of the propulsion pump is 0.7 milliliters / hour; Link to eac...

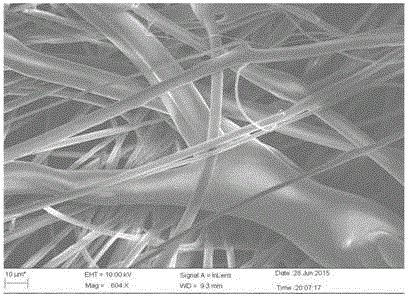

Embodiment 2

[0034] A method for preparing a heat-cured electrospun egg white protein micro-nano fiber membrane, comprising the following steps:

[0035] (1) Add 0.075 grams of polyethylene oxide (PEO, AldrichChemistry) to the Erlenmeyer flask, then add 5 grams of fresh egg white, and stir with a magnetic stirrer to fully dissolve the PEO in the egg white, and prepare it as a spinning precursor liquid;

[0036] (2) Inhale the prepared precursor solution into a 5 ml syringe and fix it on the propulsion pump 1. The flow of the spinning precursor solution is controlled by the propulsion pump 1, and the propulsion pump is turned on. The propulsion rate of the propulsion pump is 0.7 ml / hour Link to each other with spinning nozzle 5 by conduit, spinning nozzle 5 internal diameters are 0.34 millimeters, open high-voltage power supply 2 and heat blower 6 and carry out electrospinning, spinning nozzle 5 is 20 centimetres to the distance of collection cylinder 4, spinning voltage 16 thousand volts,...

Embodiment 3

[0038] A method for preparing a heat-cured electrospun egg white protein micro-nano fiber membrane, comprising the following steps:

[0039] (1) Configure the spinning precursor solution: add 1.3 grams of polyvinylpyrrolidone (PVP, BODI) in the Erlenmeyer flask, then add 5 grams of deionized water, stir with a magnetic stirrer, and stir for 2 hours at room temperature to make PVP is fully dissolved and prepared into solution A. Add 5 grams of fresh egg white to the conical flask equipped with prepared solution A, and stir with a magnetic stirrer to fully mix solution A and egg white to prepare a spinning precursor;

[0040] (2) Electrospun fiber: Inhale the prepared precursor solution into a 5 ml syringe and fix it on the propulsion pump 1. The flow of the spinning precursor solution is controlled by the propulsion pump 1, and the propulsion pump is turned on. The propulsion rate of the propulsion pump is 0.8 milliliters / hour; Link to each other with spinning nozzle 5 by condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com