Stannous sulfide and magnesium-doped zinc oxide thin film solar cell and preparation method thereof

A zinc oxide thin film and solar cell technology, which is applied in the manufacture of circuits, electrical components, and final products, and can solve problems such as unstable performance, restricted development, and decreased fill factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

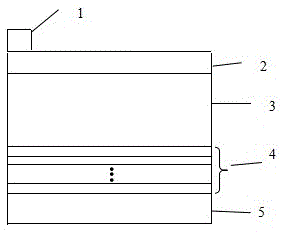

[0017] Embodiment 1: A kind of preparation method of stannous sulfide and magnesium-doped zinc oxide thin-film solar cell, operates according to the following steps:

[0018] Take a clean FTO transparent conductive glass substrate, and use the magnetron sputtering method to sequentially deposit four layers of n-type magnesium-doped zinc oxide (Zn 1-x Mg x O) film; then use plasma-enhanced chemical vapor deposition (PECVD) on the n-type Mg-doped zinc oxide (Zn 1-x Mg x O) Deposit a p-type tin sulfide (SnS) film on the film stack; then evaporate a layer of aluminum film on the p-type tin sulfide (SnS) film, and use the electrochemical anodic oxidation method to oxidize the aluminum film to make it porous aluminum oxide film (PAA); finally, the metal silver electrodes are respectively drawn from the p-type tin sulfide film and the FTO transparent conductive glass substrate by screen printing method, that is, the thin film solar cell of the present invention is obtained.

Embodiment 2

[0020] This embodiment makes a kind of tin sulfide and magnesium-doped zinc oxide thin-film solar cell, similar to embodiment 1, the difference is that ITO conductive glass is used as the substrate, and magnetron sputtering is used on the ITO transparent conductive glass substrate successively. Deposit three layers of n-type magnesium-doped zinc oxide (Zn 1-x Mg x O) Thin film lamination.

Embodiment 3

[0022] This embodiment makes a kind of tin sulfide and magnesium-doped zinc oxide thin-film solar cell, similar to embodiment 1, the difference is that AZO conductive glass is used as the substrate, and magnetron sputtering is used on the AZO transparent conductive glass substrate sequentially. Deposit two layers of n-type magnesium-doped zinc oxide (Zn 1-x Mg x O) Thin film lamination.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com