Solar energy and geothermal energy assisted CO2 Rankine cycle assisted decarbonization and denitrification system for coal-fired unit

A technology of coal-fired unit and Rankine cycle, which is applied in the direction of gas treatment, dispersed particle separation, membrane technology, etc., can solve the problems of large heat consumption, unfavorable economic and safe operation of the unit, and achieve the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

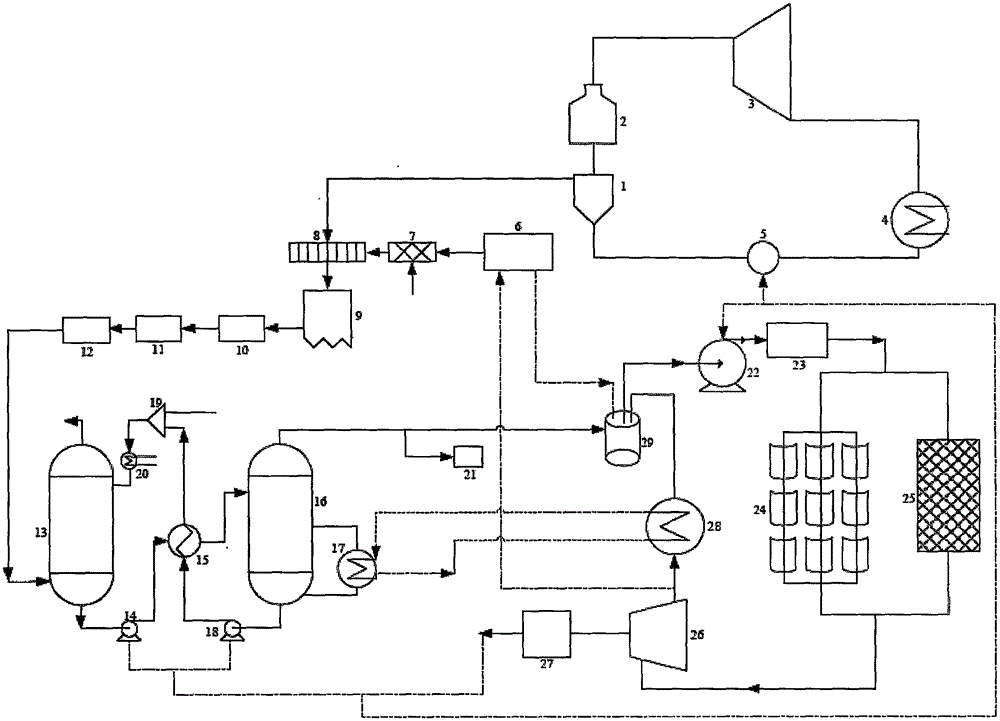

[0016] Such as figure 1 Shown, the solar geothermal energy CO of the present invention 2 Rankine cycle auxiliary decarbonization and denitrification system for coal-fired units, including coal-fired power generation system, denitrification and desulfurization system, monoethanolamine CO 2 Absorption systems, solar and geothermal assisted supercritical CO 2 Rankine cycle system;

[0017] The coal-fired power generation system includes an economizer 1, a boiler 2, a steam turbine 3, a condenser 4 and a condensate pump 5 connected in sequence, and the condensate pump 5 is connected to the economizer 1;

[0018] The denitration and desulfurization system includes a liquid ammonia evaporator 6, an ammonia gas / air mixer 7, an ammonia injection grid equipment 8, a denitration reactor 9, an air preheater 10, an electrostatic precipitator 11 and a desulfurization system 12 connected in sequence, The ammonia injection grid equipment 8 is connected to the economizer 1;

[0019] The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com