Preparation method of nitrogen-doped fluorescent carbon dots

A technology of fluorescent carbon dots and nitrogen doping, applied in the field of preparation of nitrogen doped fluorescent carbon dots, can solve the problems of low product yield, uncontrollable size, and poor crystallinity of carbon dots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

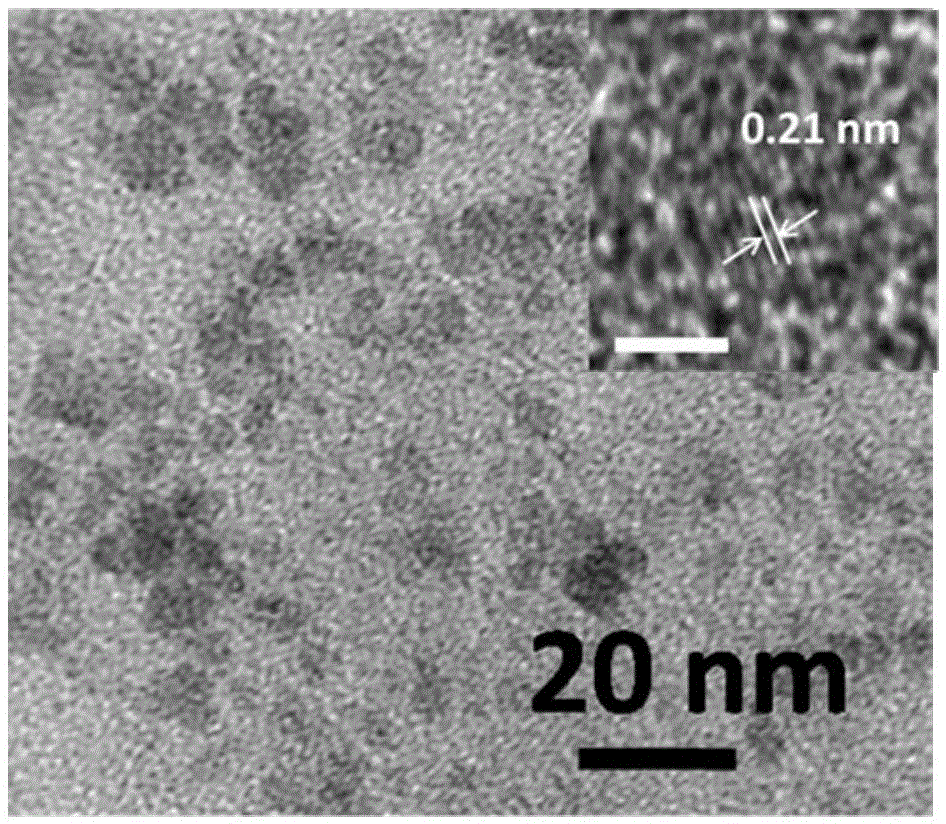

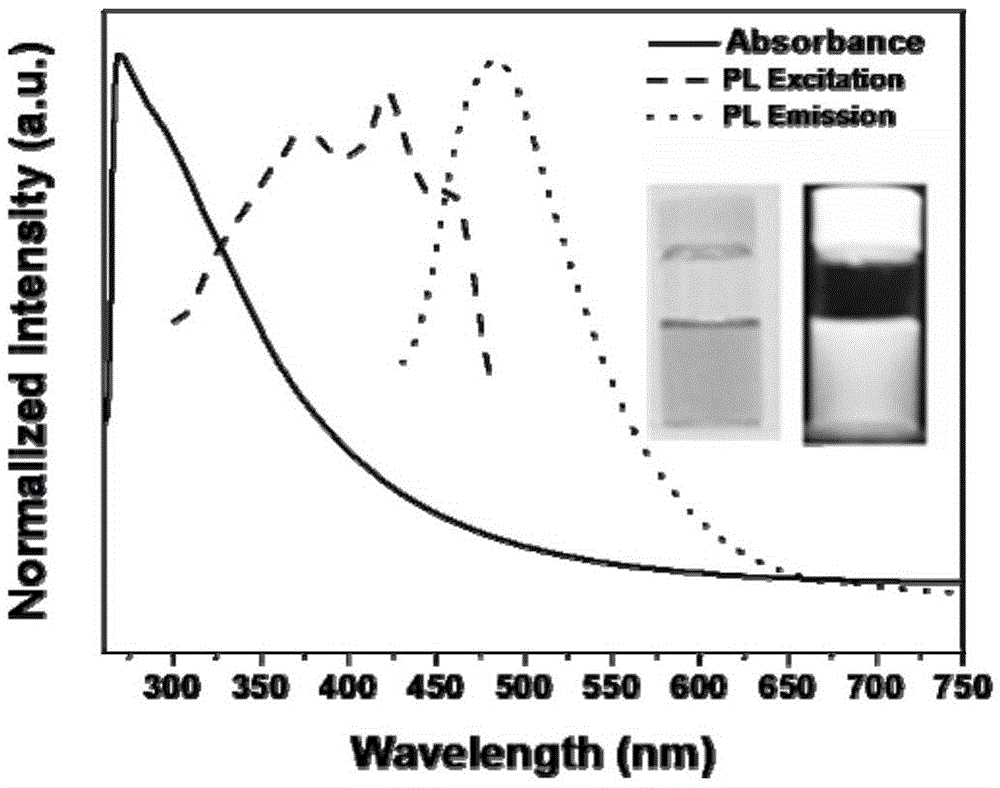

[0019] Crush and grind the anthracite, sieve it with a 200-mesh screen, dry it in an oven at 100°C for 5 hours, cool to room temperature, weigh 504 mg of anthracite dried in the oven and place it in a 50 ml beaker, then add 20 ml of dimethylformamide , stir well, disperse the carbon source evenly and ultrasonically for 1.2h, then put the mixture in a 50ml hydrothermal kettle, and conduct a hydrothermal reaction at 180°C for 12h; After centrifuging at a speed of 9000rpm in a high-speed desktop centrifuge for 20 minutes, take the supernatant to obtain the hydrosol of fluorescent carbon dots; then place the hydrosol of fluorescent carbon dots in a rotary evaporation device, and after removing the organic solvent, the powdery Fluorescent carbon dots. Taking the fluorescent dye quinine sulfate as a reference, the quantum yield of the prepared fluorescent carbon dots reaches 12.5%, and taking anthracite as a reference, the product yield is 11.1wt.%. The morphology of the obtained t...

Embodiment 2

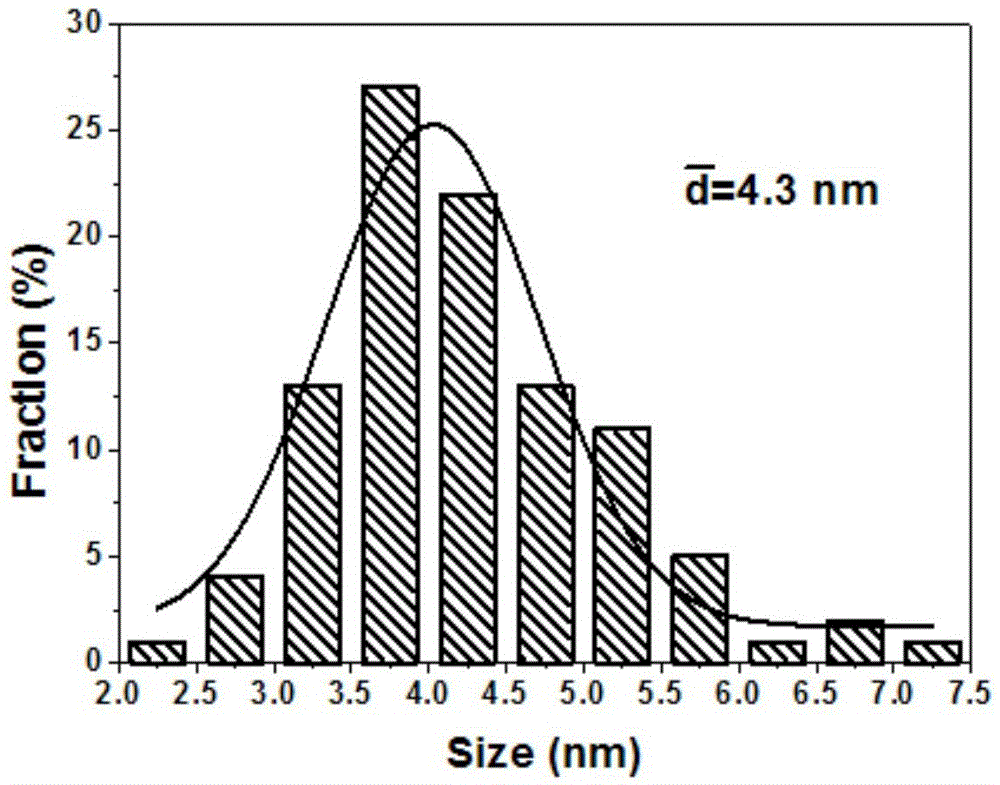

[0021] Grind the graphite powder, sieve it with a 200-mesh sieve, dry it in an oven at 110°C for 5 hours, cool to room temperature, weigh 504mg of the oven-dried graphite powder and place it in a 50ml beaker, then add 20ml of dimethyl formaldehyde Amide, stir well, disperse the carbon source evenly and sonicate for 1.2h, then put the mixture in a 50ml hydrothermal kettle, and conduct a hydrothermal reaction at 180°C for 12h; after the above reaction is completed, wait for the hydrothermal kettle to cool to room temperature, and take out the suspension After centrifuging at a speed of 9000rpm in a high-speed desktop centrifuge for 18 minutes, take the supernatant to obtain the hydrosol of fluorescent carbon dots; then place the hydrosol of fluorescent carbon dots in a rotary evaporation device to obtain powdered Fluorescent carbon dots. The resulting particle size distribution is figure 2 shown.

Embodiment 3

[0023] Crush and grind the bituminous coal, sieve it with a 200-mesh screen, dry it in an oven at 105°C for 6 hours, cool to room temperature, weigh 200 mg of bituminous coal dried in the oven and place it in a 50 ml beaker, then add 10 ml dimethylformamide , stir well, disperse the carbon source evenly and ultrasonically for 0.8h, then put the mixture in a 50ml hydrothermal kettle, and conduct a hydrothermal reaction at 80°C for 10h; After centrifuging at 8500rpm in a high-speed desktop centrifuge for 10 minutes, take the supernatant to obtain the hydrosol of fluorescent carbon dots; then place the hydrosol of fluorescent carbon dots in a rotary steamer, remove the organic solvent, and obtain powdered fluorescent carbon dots. Carbon dots.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com