Saline-alkali soil conditioner as well as preparation and application thereof

A saline-alkali soil and improver technology, applied in the fields of application, soil conditioning materials, organic fertilizers, etc., can solve the problems of lack and inability to meet the needs of sludge treatment, etc., to promote crop growth, long-term improvement of saline-alkali land, and increase soil fertility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1, the preparation of saline-alkali soil conditioner of the present invention

[0057] Material preparation:

[0058] Ratio of main ingredients: 100g of main ingredients include 60.0-80.0g of sludge with a water content of 60.0-90.0%, 10.0-20.0g of humus, peat or farm manure (naturally decomposed livestock manure) and 10.0-30.0g of water, In addition, add 0.1-0.5g of deodorizing and sterilizing agent composed of trichloroisocyanuric acid to deodorize and sterilize the main ingredients;

[0059] Ingredients ratio: 100.0g acrylic resin modified casein or polyacrylamide and its derivatives or lignosulfonate or cellulose derivatives;

[0060] The auxiliary material is 100.0g of compound microbial bacterial agent: the weight components of various bacterial strains are as follows: 10.0-15.0 parts of anaerobic lactic acid bacteria group, 10.0-15.0 parts of aerobic yeast group, and 10.0-15.0 parts of aerobic Gram-positive actinomycete group 10.0-15.0 parts, anaerob...

Embodiment 2

[0066] Take 6000.0g of sludge with a water content of 60.0%, 1000.0g of farm manure (naturally decomposed livestock and poultry manure) and 1000.0g of water, and add 10.0g of trichloroisocyanuric acid to deodorize the main ingredients. Made into main ingredients after sterilization;

[0067] Get 400.0g acrylic resin modified casein as auxiliary material;

[0068] Lactic acid bacteria (aerobic), yeast flora (aerobic), Gram-positive actinomycetes (aerobic), filamentous bacteria of fermentation systems (aerobic), Bacillus, nitrogen-fixing bacteria, 10.0 g each of the phosphate solubilizing bacteria and the potassium solubilizing bacteria are mixed and used as ingredients.

[0069] Prepare the main ingredients, spare auxiliary ingredients and ingredients that have been made respectively.

[0070] The main ingredient is diluted with 1-2 times the weight of water for later use; the auxiliary material is diluted with 1-2 times the weight of water for later use, and the diluted auxi...

Embodiment 3

[0071] Embodiment 3, the application of saline-alkali land improvement agent of the present invention

[0072] On the land to be treated, use a sprayer to spray the filtrate obtained in Example 1 and / or Example 2 to form a mulch film. The orifice diameter on the nozzle of the sprayer is 1.0 to 1.5mm. It is necessary to maintain a certain pressure and prevent clogged.

[0073] Stepping and shoveling should be avoided within 90 days of spraying.

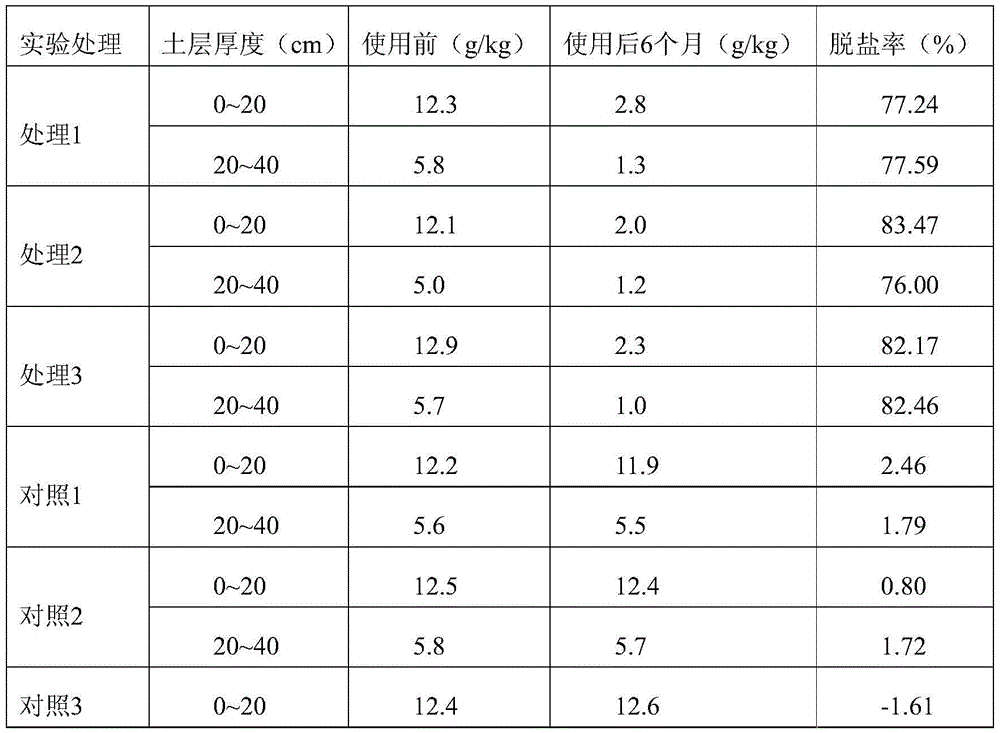

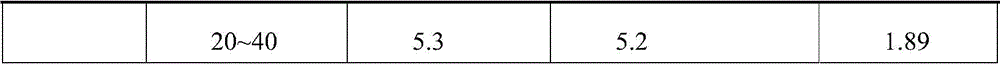

[0074] Generally, it is recommended to spray saline-alkali soil improver (the weight of the filtrate after the main material, auxiliary material and ingredients are mixed with water) per mu of saline-alkali land, 10.0kg ~ 30kg. After the field pilot test, the results are shown in the table below.

[0075]

[0076]

[0077] By using the saline-alkali soil improver of the invention, the total salt content of the soil is reduced by more than 80% compared with the soil without using the saline-alkali soil improver, and the soil fert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com