Allyl isothiocyanate double-layer micro-capsule sustained release agent taking chitosan as carrier, and preparation method thereof

A technology of horseradish and sustained-release agent, which is applied in the field of horseradish double-layer microcapsule sustained-release agent and its preparation, can solve the problems of reducing drug burst release and short sustained-release effect, so as to improve the safety of use and extend the Long-lasting effect and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

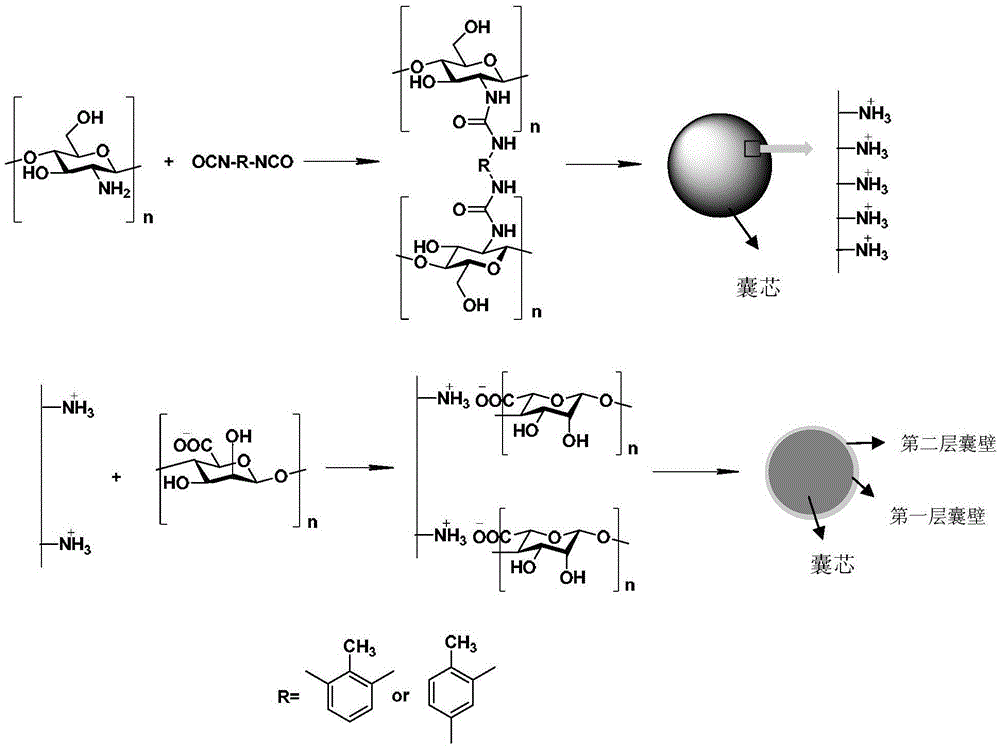

Method used

Image

Examples

Embodiment 1

[0037] 1. Preparation method

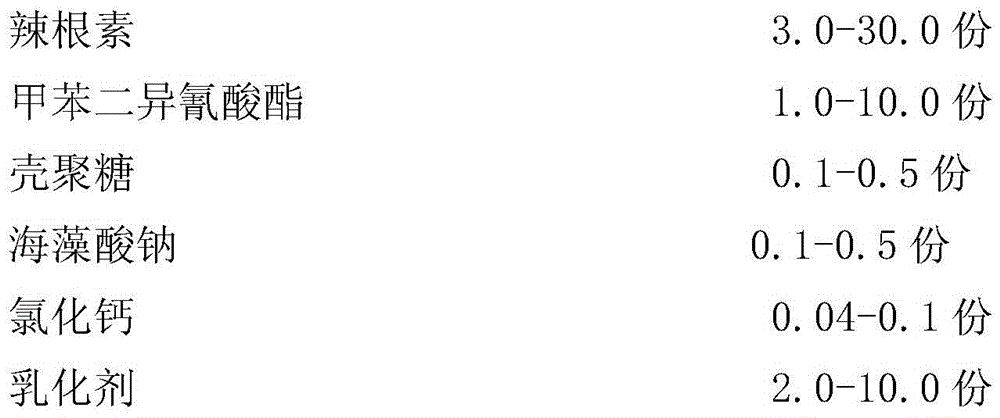

[0038] 1) Preparation of horseradish single-layer microcapsule sustained-release agent: 10.0g horseradish, 1.5g toluene-2,4-diisocyanate, 6.0g emulsifier (phenylethylphenol polyoxyethylene polyoxypropylene ether 4.0 g, calcium dodecylbenzenesulfonate 2.0g) fully mix and stir, then add 20.0g aqueous acetic acid containing 2% chitosan, adopt 6000 rpm high-speed shear emulsifier to shear and stir emulsification for 4min, drop Add two drops of polydimethylsiloxane for defoaming, change the speed to 600 rpm and continue stirring for 1 hour to obtain chitosan monolayer microcapsules of horseradish;

[0039] 2) Preparation of horseradish double-layer microcapsules: Slowly add 20 g of an aqueous solution with a content of 2% sodium alginate to the horseradish single-layer microcapsule slow-release agent prepared above, continue stirring for 40 minutes, and then slowly drop 4g of 2% calcium chloride aqueous solution, fully stirred evenly, added 38.5g of ...

Embodiment 2

[0045] 1. Preparation method

[0046] 1) Preparation of horseradish single-layer microcapsule sustained release agent: 20.0g horseradish, 5.0g toluene-2,6-diisocyanate, 10.0g emulsifier (castor oil polyoxyethylene ether) were fully mixed and stirred evenly, Then add 25.0 g of sulfuric acid aqueous solution containing 2% chitosan, use 8000 rpm high-speed shear emulsifier to shear and stir emulsification for 3 minutes, add two drops of polypropylene glycol, and change it to 400 rpm and stir for 1 hour to obtain Chitosan monolayer microcapsules of horseradish.

[0047] 2) Preparation of horseradish double-layer microcapsules: Slowly add 10 g of an aqueous solution of 2% sodium alginate to the single-layer microcapsules prepared above, continue stirring for 40 minutes, and slowly add 2 g of 2% calcium chloride aqueous solution dropwise , fully stir evenly, add 28g content and be 1% gum arabic aqueous solution and stir evenly, adjust the pH value to 6.8 with a few drops of 10% sod...

Embodiment 3

[0053] 1. Preparation method

[0054] 1) Preparation of horseradish single-layer microcapsule sustained-release agent: 30.0g horseradish, 8.0g toluene-2,4-diisocyanate, 2.0g toluene-2,6-diisocyanate, 10.0g emulsifier (ricin Sesame oil polyoxyethylene ether 8.0g, sodium dodecylbenzene sulfonate 2.0g) fully mix and stir, then add 15.0g phosphoric acid aqueous solution containing 2% chitosan, adopt 10000 rev / min high-speed shear emulsifying machine to shear Cut, stir and emulsify for 5 minutes, add two drops of polypropylene glycol dropwise, change the speed to 400 rpm and stir for 1 hour to obtain chitosan monolayer microcapsules of horseradish.

[0055] 2) Preparation of horseradish double-layer microcapsules: Slowly add 10 g of an aqueous solution of 2% sodium alginate to the above-prepared horseradish single-layer microcapsules, continue stirring for 40 minutes, and then slowly add 3 g of 2% chlorine Calcium chloride aqueous solution, fully stirred evenly, added 22 g of 0.5%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com