Advanced treatment device for nitrogen-containing heterocyclic ring compound chemical tail water and combination technology thereof

A nitrogen heterocyclic compound and combined process technology, which is applied in the directions of oxidized water/sewage treatment, electrochemical water/sewage treatment, water/sewage treatment, etc. Stable and efficient degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

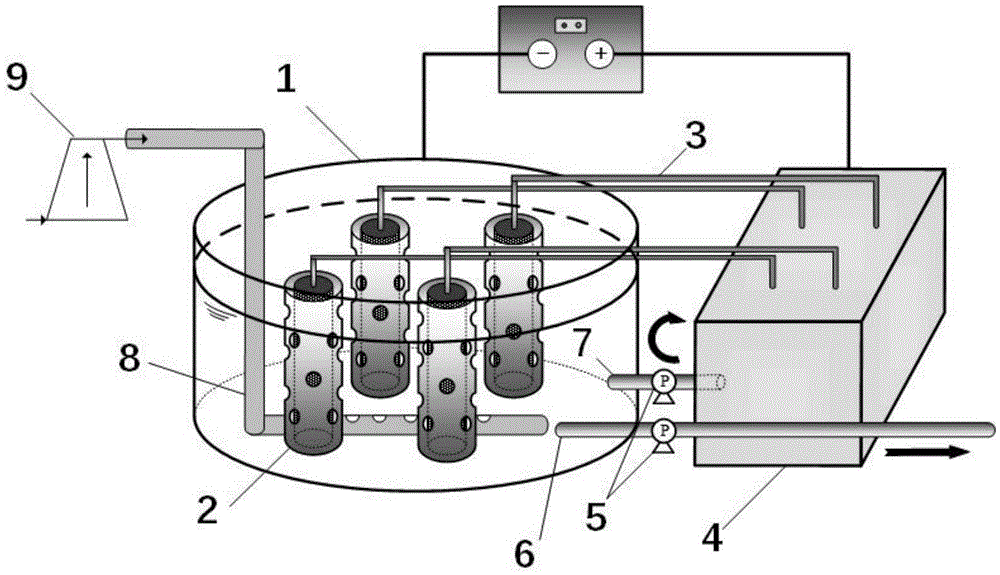

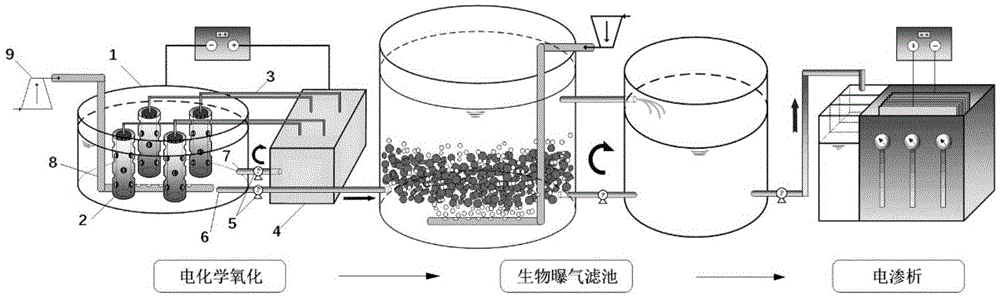

[0038] The combined process of electrochemical oxidation-biological aeration filter-electrodialysis was used to treat the tail water of pesticide production containing tricyclazole (TC).

[0039] Influent COD=234.80mg / L, tricyclazole concentration 178.47mg / L, pH=7.2, SS=850mg / L in tail water containing tricyclazole (TC) pesticide.

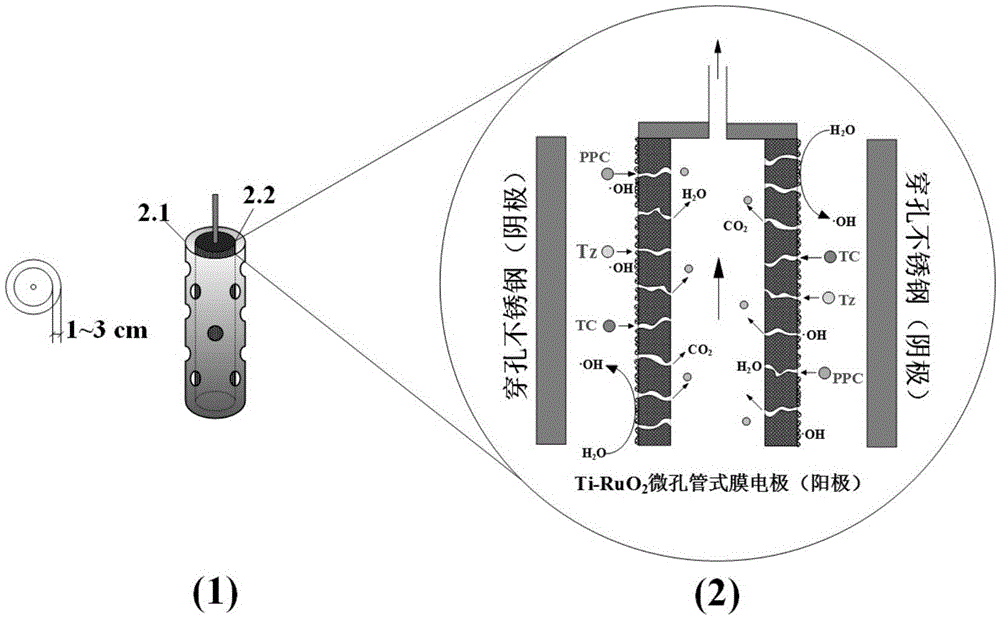

[0040] Step 1. The tail water is pretreated by an electrochemical oxidation method. About 8 cubic meters of tail water is injected into the reaction tank, the electrode reactor is submerged, the aeration pipeline switch is turned on for aeration, the DC power supply is turned on, the constant current is controlled at 260A, and the voltage is 3.4V. Then turn on the high-pressure water pump switch, set the high-pressure water pump to work once every 20 minutes, and work once every 5 minutes. The distance between the cathode and anode of the electrochemical oxidation reactor is 1 cm. The nitrogen-containing heterocyclic compound in the wastewater und...

Embodiment 2

[0048] The tail water containing propiconazole (PPC) pesticide was treated by electrochemical oxidation-biological aeration filter-electrodialysis.

[0049] Influent COD=258.70mg / L, propiconazole concentration 41.15mg / L, pH=7.3, SS=960mg / L in tail water containing propiconazole (PPC) pesticide production.

[0050] Step 1. The tail water is pretreated by an electrochemical oxidation method. About 9 cubic meters of tail water is injected into the reaction tank, the electrode reactor is submerged, the aeration pipeline switch is turned on for aeration, the DC power supply is turned on, and the constant current is controlled at 210A and the voltage is 3.0V. Then turn on the high-pressure water pump switch, set the high-pressure water pump to work once every 30 minutes, and work once every 10 minutes. The distance between the cathode and anode of the electrochemical oxidation reactor is 2 cm. The nitrogen-containing heterocyclic compound in the wastewater undergoes an instantaneou...

Embodiment 3

[0056] Electrochemical oxidation-biological aeration filter-electrodialysis was used to treat the tail water containing triazole (Tz) pesticides.

[0057] Influent COD=249.63mg / L, triazole concentration 72.10mg / L, pH=7.5, SS=950mg / L in tail water of pesticide production containing triazole (Tz).

[0058] Step 1. The tail water is pretreated by an electrochemical oxidation method. About 10 cubic meters of tail water is injected into the reaction tank, the electrode reactor is submerged, the aeration pipeline switch is turned on for aeration, the DC power supply is turned on, the constant current is controlled at 300A, and the voltage is 3.9V. Then turn on the high-pressure water pump switch, set the high-pressure water pump to work once every 10 minutes, and work once every 8 minutes. The distance between cathode and anode of the electrochemical oxidation reactor is 3 cm. The nitrogen-containing heterocyclic compound in the wastewater undergoes an instantaneous electrochemical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com