Nano cellulose whisker grafted water-diluted photocuring PUV (polyurethane acrylate) resin, and preparation and application thereof

A nanocellulose, water dilution technology, applied in the field of coatings, can solve problems such as poor mechanical properties, and achieve the effects of good mechanical properties, good adhesion, good storage stability and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In this embodiment, the molar ratio of hydroxypropyl acrylate to pentaerythritol triacrylate is 2:3, and the mass of nanocellulose whiskers accounts for 0.5% of the total mass of the final obtained PUA resin solids.

[0048] (1) Synthesis of polyurethane prepolymer I: Add 28.7g of toluene-2,4-diisocyanate (TDI-80) and 27.5g of polyoxypropylene glycol (Mw =1000), drop 0.056g catalyst dibutyltin dilaurate, react in a constant temperature water bath, heat up to 85°C, keep this temperature for about 1.5h, and the NCO value of di-n-butylamine titration reaches or is slightly lower than the theoretical When the value is , the semi-blocked polyurethane prepolymer I is obtained;

[0049] (2) Synthesis of polyurethane prepolymer II: cool down to 65°C, weigh 9.3g of dimethylolpropionic acid (DMPA), dissolve it with 27.9g of acetone, place it in a dropping funnel, and drop it into a four-necked flask. The dropping rate is 3 s / drop, keep this temperature for 3 hours, add a proper ...

Embodiment 2

[0055] In this embodiment, the molar ratio of hydroxypropyl acrylate to pentaerythritol triacrylate is 2:3, and the mass of nanocellulose whiskers accounts for 2.5% of the total mass of the final obtained PUA resin solids.

[0056] (1) Synthesis of polyurethane prepolymer I: add 30.1g of toluene-2,4-diisocyanate (TDI-80) and 28.8g of polyoxypropylene glycol (Mw =1000), add dropwise 0.059g catalyst dibutyltin dilaurate, react in a constant temperature water bath, heat up to 85°C, keep this temperature for about 1.5h, and the NCO value of di-n-butylamine titration reaches or is slightly lower than the theoretical When the value is , the semi-blocked polyurethane prepolymer I is obtained;

[0057] (2) Synthesis of polyurethane prepolymer II: cool down to 65°C, weigh 9.8g of dimethylolpropionic acid (DMPA), dissolve it with 29.4g of acetone, place it in a dropping funnel, drop it into a four-necked flask, The dropping rate is 3 s / drop, keep this temperature for 3 hours, add a pro...

Embodiment 3

[0063] In this embodiment, first add nanocellulose whiskers to react with polyurethane prepolymer I, and then react with dimethylol propionic acid, wherein the molar ratio of hydroxypropyl acrylate to pentaerythritol triacrylate is 2:3, and nanocellulose The mass of whiskers accounts for 2.5% of the total mass of the final obtained PUA resin solids.

[0064] Preparation:

[0065](1) Synthesis of polyurethane prepolymer I: add 30.1g of toluene-2,4-diisocyanate (TDI-80) and 28.8g of polyoxypropylene glycol (Mw =1000), add dropwise 0.059g catalyst dibutyltin dilaurate, react in a constant temperature water bath, heat up to 85°C, keep this temperature for about 1.5h, and the NCO value of di-n-butylamine titration reaches or is slightly lower than the theoretical When the value is , the semi-blocked polyurethane prepolymer I is obtained;

[0066] (2) Graft polymerization of nanocellulose whiskers: cool down to 60°C, disperse 0.688g of self-made nanocellulose whiskers in 6.9g of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

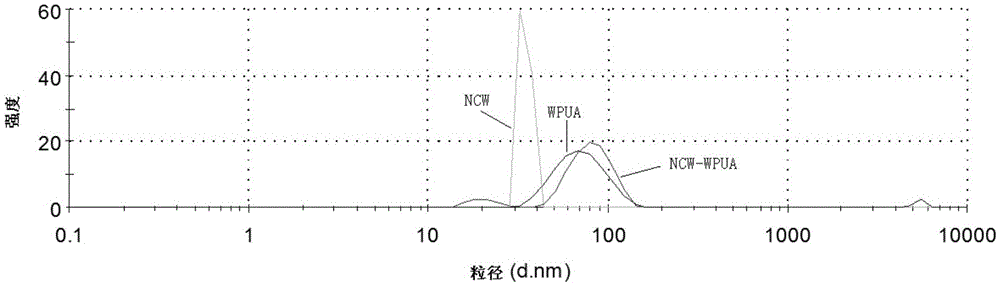

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com