Negative electrode for non-aqueous electrolyte secondary battery, material for non-aqueous electrolyte secondary battery, method of preparing material, and lithium-ion secondary battery

A non-aqueous electrolyte and secondary battery technology, applied in secondary batteries, battery electrodes, batteries, etc., can solve the problems of inability to form a uniform carbon film, decrease in cycle performance, and large irreversible capacity, and achieve excellent cycle stability. Effects of small variation in efficiency and good cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0113] As the production method of the negative electrode (molded body), for example, the following methods can be cited. In the negative electrode material for the above-mentioned non-aqueous electrolyte secondary battery, other additives such as conductive agents and binders added as required, solvents such as N-methylpyrrolidone or water are added, mixed into a gel-like mixture, and the The mixture is coated on the current collector sheet. At this time, as the current collector, if it is a material generally used as a negative electrode current collector, such as copper foil and nickel foil, it can be used without limitation in particular thickness and surface treatment. Furthermore, the molding method for molding the mixture into a sheet shape is not particularly limited, and known methods can be used.

[0114]

[0115] The lithium ion secondary battery of the present invention includes the negative electrode of the present invention described above. Known materials su...

Embodiment 1 to Embodiment 4

[0145] (Example 1 to Example 4, Comparative Example 1, Comparative Example 2)

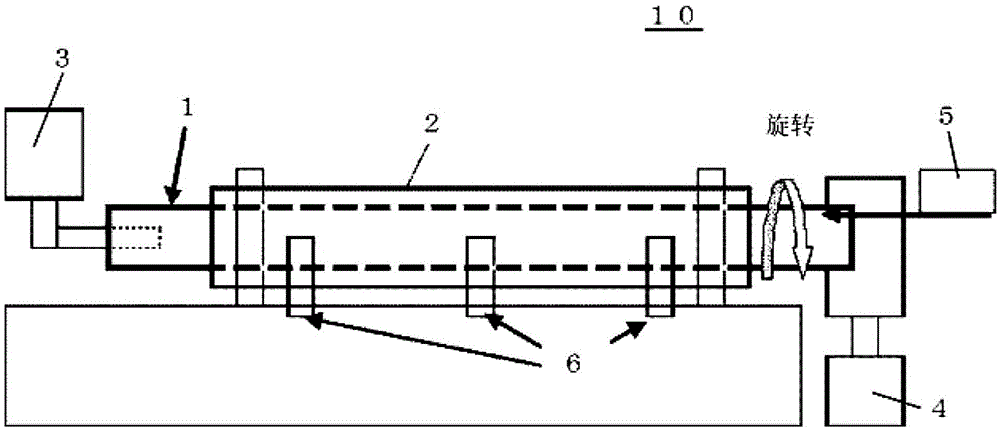

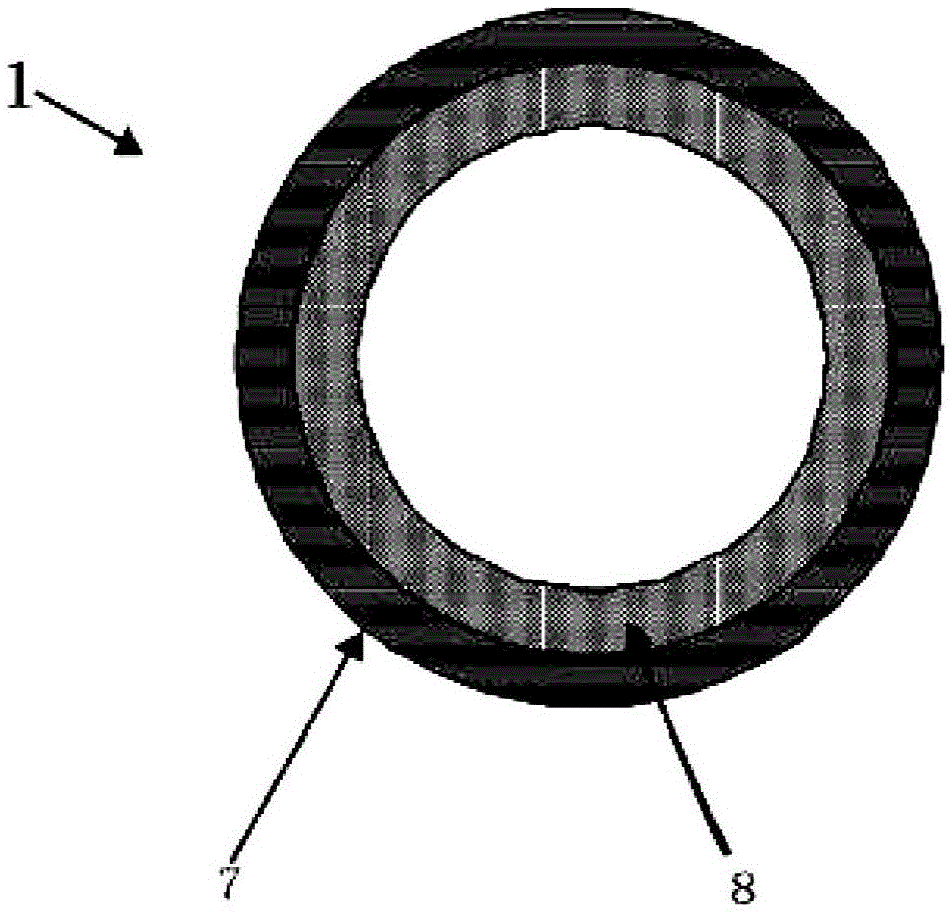

[0146] use as figure 1 Shown rotary kiln, the mass W ( kg / h), the inner diameter T (m) of the furnace core tube is controlled, and a carbon film is formed on the particle surface of the silicon-based negative electrode active material. At this time, the disproportionation of the particles of the silicon-based active material also proceeds simultaneously. At this time, the furnace length L of the furnace tube was set at 8.5 m, and the temperature inside the furnace tube was set at 950°C. In addition, the furnace core tube was inclined by 1 degree relative to the horizontal plane, methane gas was used as the hydrocarbon gas, and argon was used as the inert gas. The introduction amount of these gases is properly adjusted, so that the amount of the carbon film formed on the surface of the particles of the silicon-based negative electrode active material of the non-aqueous electrolyte secondary batte...

Embodiment 5 to Embodiment 8、 comparative example 3

[0167] (Example 5 to Example 8, Comparative Example 3, Comparative Example 4)

[0168] Basically, the carbon film is formed on the particle surface of the silicon-based negative electrode active material in the same manner as in the above-mentioned embodiment 1, but as shown in the following table 2, the number of revolutions R (rpm) of the furnace core tube is changed, and the furnace core is dropped into The mass W (kg / h) per unit time of the particles of the silicon-based negative electrode active material in the tube, and the inner diameter T (m) of the furnace core tube. In addition, the furnace length L of the furnace tube at this time was 3 m, and the temperature inside the furnace tube was 1040°C.

[0169] Further, the particles of the silicon-based negative electrode active material use SiO x (x=1.01) and average particle size (D 50 ) is silicon oxide of 4 μm. In addition, the average particle diameter mentioned here is the volume average particle diameter in the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com