Method and device for treating oilfield wastewater

A technology for oil extraction sewage and treatment equipment, which is applied in mining wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of large dosage of chemicals and insignificant reduction in COD, and achieves good results and increased Decontamination effect, effect of increasing water supply pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

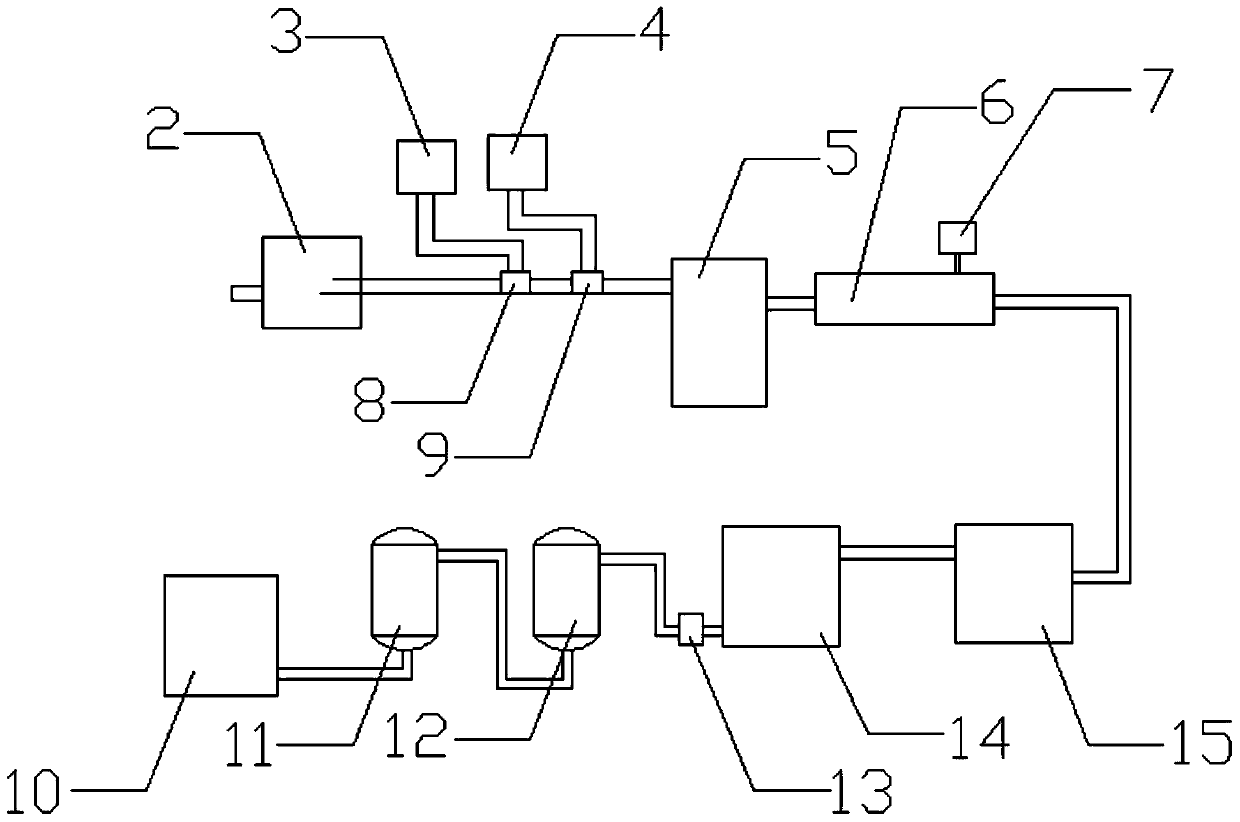

[0033] A sewage treatment device for oilfield extraction, such as figure 1 As shown, it includes a dealkalizing device 2, an electrochemical treatment device 5, an air flotation machine 6, a dissolved air pump 7, an inclined tube sedimentation tank 15, a first water tank 14, a pressure pump 13, a dual filter material filter 12, and dynamic membrane filtration Device 11 and the second pool 10, the dealkalizing device 2, the electrochemical treatment device 5, the air flotation machine 6, the inclined tube sedimentation tank 15, the first pool 14, the double filter material filter 12, the dynamic membrane filter 11 and The second pool 10 is provided with a feed port and a feed port. The feed port of the dealkalizing device 2 is in communication with the feed port of the electrochemical treatment device 5, and the discharge port of the electrochemical treatment device 5 is connected to the gas The feed port of the floater 6 is in communication, the discharge port of the air floate...

Embodiment 2

[0036] A method for processing oilfield wastewater from oil production is carried out by using the device provided in Example 1. Specific steps are as follows:

[0037] (1) Dealkalizing treatment: input poly-oily wastewater and ternary oily wastewater into the dealkalizing device, and use a DC power supply to establish a DC electric field in the ternary oily wastewater. Metal sodium ions move in the electric field along the current direction and set in the DC electric field. Cationic membrane, the left side of the cation membrane is sewage, and the right side is tap water. Insert a conductive electrode in the sewage on the left to connect to the negative electrode of the power supply, and insert a conductive electrode into the negative electrode of the power supply in the tap water on the right. Enriched. The ionization reaction of the two-sided electrode on the water can transfer more than 90% of the caustic soda in the sewage to the tap water, so that the concentration in the ...

Embodiment 3

[0044] A method for processing oilfield wastewater from oil production is carried out by using the device provided in Example 1. Specific steps are as follows:

[0045] (1) Dealkalizing treatment: input poly-oily wastewater and ternary oily wastewater into the dealkalizing device, and use a DC power supply to establish a DC electric field in the ternary oily wastewater. Metal sodium ions move in the electric field along the current direction and set in the DC electric field. Cationic membrane, the left side of the cation membrane is sewage, and the right side is tap water. Insert a conductive electrode in the sewage on the left to connect to the negative electrode of the power supply, and insert a conductive electrode into the negative electrode of the power supply in the tap water on the right. Metal sodium ions penetrate the ion membrane into the tap water in the direction of the electric field. Enriched. The ionization reaction of the two-sided electrode on the water can tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com