Device and method for jointly preparing bio-oil and multihole biochar through fuse salt by spraying biomass for pyrolysis

A combined preparation and biomass technology, applied in biofuel, petroleum industry, direct heating and dry distillation, etc., can solve the problems of low biomass density, difficult to fully contact, difficult to control molten salt pyrolysis process, etc., to achieve simple separation and structure Simple and compact, the effect of improving mass transfer and heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

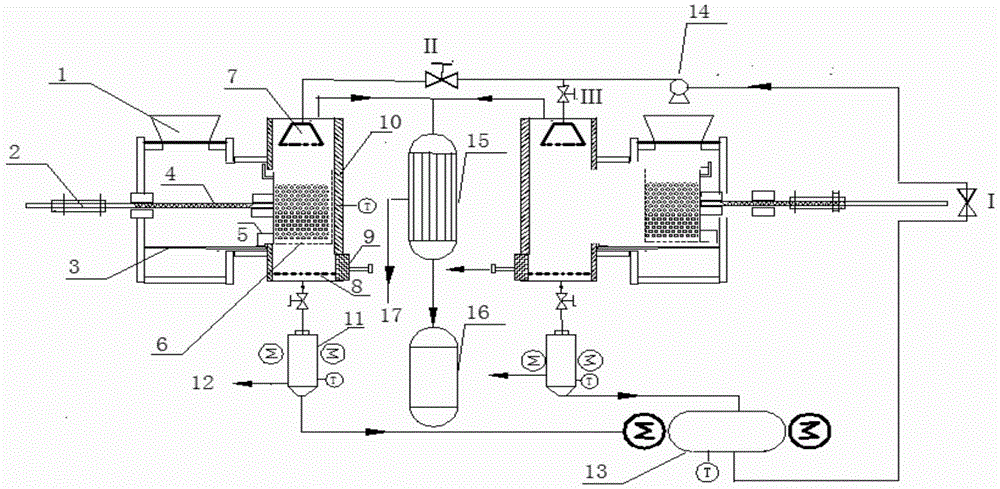

[0024] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0025] ZnCl 2 Preparation of bio-oil and porous biochar by pyrolyzing corn cob particles with KCl mixed molten salt

[0026] Zinc chloride with catalytic and activating effects and low-temperature molten salt composed of potassium chloride (molar ratio 7 / 6) are selected. The molten salt has a low melting point and maintains good stability at 200-500°C to meet the rapid pyrolysis of biomass temperature. The temperature of the molten salt pool is controlled at 500°C, and the temperature of the pipeline is controlled at 450°C. Weigh 10g of corn cob particles with a particle size of 1-3mm and transport them to the No. 1 spray pyrolysis device through the material basket by a linear thread stepping method, and use high-purity N2 (99.99%) with a flow rate of 100ml / min to purge and pyrolyze After 10 minutes in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com