Firecracker-shaped titanium dioxide/polyimide nano hybrid fiber preparation method

A polyimide and nanofiber technology, applied in the field of fibers, can solve problems such as unfavorable promotion and complexity, and achieve the effects of wide range of use, high photocatalysis and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

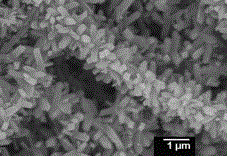

Embodiment 1

[0023] Using pyromellitic anhydride / 4,4'-diaminodiphenylmethane polyamic acid with a solid content of 15%, the polyamic acid was obtained by high-voltage electrospinning, and the polyimide nanometer was prepared by the thermal imide process. fiber.

[0024] Put the polyimide nanofibers prepared above into an autoclave containing 0.001 g / mL titanium foil and 0.05 mol / L hydrochloric acid. The firecracker-like titanium dioxide / polyimide nano-hybrid fibers were prepared by reacting at 170°C for 12 hours.

Embodiment 2

[0026] Using 3,3',4,4'-biphenyltetracarboxylic dianhydride / 4,4'-diaminodiphenyl ether polyamic acid with a solid content of 20%, the polyamic acid was obtained by high-voltage electrospinning, and the polyamic acid was obtained by thermal acyl The polyimide nanofibers were prepared by the imide process.

[0027] Put the polyimide nanofibers prepared above into an autoclave containing 0.002 g / mL titanium powder and 0.1 mol / L hydrochloric acid. Firecracker-like titanium dioxide / polyimide nano-hybrid fibers were prepared by reacting at 150°C for 8 hours.

Embodiment 3

[0029] Using 3,3',4,4'diphenyl ether tetracarboxylic dianhydride / 4,4'-diaminodiphenyl ether polyamic acid with a solid content of 17%, the polyamic acid was obtained by high-voltage electrospinning, and the polyamic acid was obtained by thermal acyl The polyimide nanofibers were prepared by the imide process.

[0030] Put the polyimide nanofibers prepared above into an autoclave containing 0.004 g / mL titanium powder and 0.05 mol / L hydrochloric acid. The firecracker-like titanium dioxide / polyimide nano-hybrid fibers were prepared by reacting at 160°C for 10 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com