A fabrication method of nitrogen-doped graphene supercapacitor based on redox active electrolyte

A nitrogen-doped graphene and supercapacitor technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve the problem of increasing the degree of pseudocapacitive active electrolyte without providing the specific capacitance data of the electrode itself , to achieve the effects of good surface hydrophilicity, improved electrode capacitance, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

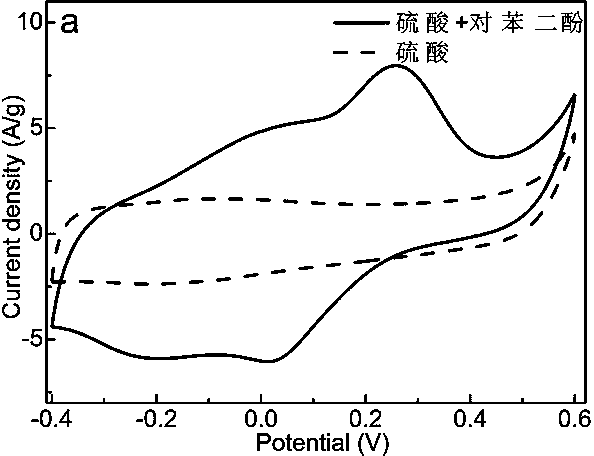

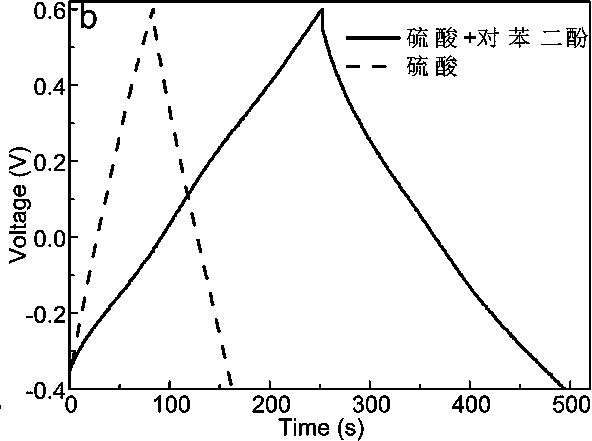

[0016] Dissolve 2.4g of the surfactant cetyltrimethylammonium bromide in an aqueous solution (40mL) containing 0.04g of graphene oxide, place the solution in an ice-water bath at 0°C, and add 2g of Ammonium persulfate and 2g of pyrrole monomer were stirred and reacted for 24h; the resulting black precipitate was washed and dried with deionized water, mixed with sodium hydroxide in a mass ratio of 1:2, placed in a nickel crucible under nitrogen gas Calcined at 600°C for 2h under the condition. After cooling, wash with dilute hydrochloric acid and deionized water to remove sodium hydroxide to obtain a nitrogen-doped porous graphene electrode material with a specific surface area of 1207m 2 / g. The obtained nitrogen-doped porous graphene electrode material, the acetylene black conductive agent and the nitrogen-methylpyrrolidone dispersion of polyvinylidene fluoride were mixed in a mass ratio of 85:10:5 and ground to form a homogeneous slurry Material, coated with 1cm on the s...

Embodiment 2

[0019] Dissolve 2.4g of the surfactant cetyltrimethylammonium bromide in an aqueous solution (40mL) containing 0.04g of graphene oxide, place the solution in an ice-water bath at 0°C, and add 4g of Ammonium persulfate and 4g pyrrole monomer were stirred and reacted for 24h; after the black precipitate was washed and dried with deionized water, it was mixed with potassium hydroxide in a mass ratio of 1:3, placed in a nickel crucible under nitrogen gas Calcined at 700°C for 2h under the condition. After cooling, it was washed with dilute hydrochloric acid and deionized water to neutrality to obtain a nitrogen-doped porous graphene electrode material with a specific surface area of 2036m 2 / g. Mix and grind the obtained nitrogen-doped porous graphene electrode material, acetylene black conductive agent and polyvinylidene fluoride nitrogen methyl pyrrolidone dispersion according to the mass ratio of 85:10:5 to form a uniform slurry , coated on the stainless steel current colle...

Embodiment 3

[0022] Dissolve 2.4g of the surfactant cetyltrimethylammonium bromide in an aqueous solution (40mL) containing 0.04g of graphene oxide, place the solution in an ice-water bath at 0°C, and add 8g of Ammonium persulfate and 8g of pyrrole monomer were stirred and reacted for 24h; after the black precipitate was washed and dried with deionized water, it was mixed with potassium hydroxide in a mass ratio of 1:4, placed in a nickel crucible under argon gas Calcined at 600°C for 2h under the condition. After cooling, potassium hydroxide was removed by washing with dilute hydrochloric acid and deionized water to obtain a nitrogen-doped porous graphene electrode material with a specific surface area of 2276m 2 / g. The nitrogen-doped porous graphene electrode material, acetylene black conductive agent and polyvinylidene fluoride binder are mixed according to the mass ratio of 85:10:5 and ground to form a uniform slurry, which is coated on the stainless steel current collector. into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com