Graphene dispersant and its application

A technology of graphene and dispersion, which is applied in the treatment of dyed polymer organic compounds, fibrous fillers, transportation and packaging, etc. It can solve the problem of inconspicuous, non-universal, chemical composition and physical morphology changes of graphene materials and other issues, to achieve the effects of low cost, large-scale implementation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

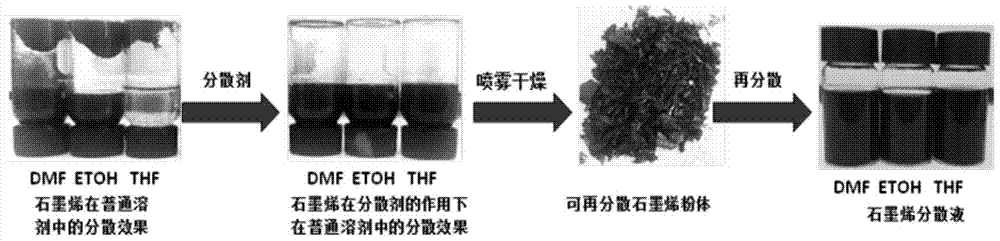

[0058] Another aspect of the present invention also provides a method for preparing a graphene dispersion, which includes: uniformly mixing graphene and the graphene dispersant in a dispersion medium to form a stable dispersion.

[0059] In some embodiments, a graphene dispersion method may include: only dissolving the graphene dispersant and graphene in an organic solvent, thereby forming a stable dispersion. It should be noted that the "dissolved" mentioned here is not understood by those of ordinary skill as dissolved, but should be understood as "incorporated", "dispersed into" or "mixed in", etc. For example, the graphene dispersant and graphene can be added into an organic solvent, and stirred or ultrasonically dispersed, for example, ultrasonically dispersed for more than 1 hour, so as to form a stable dispersion liquid.

[0060] More preferably, the dispersion contains graphene at a concentration of 1 mg / ml-10 mg / ml.

[0061] In the graphene dispersion method, the mol...

Embodiment 1

[0078] Example 1 polyethylene glycol grafted aniline tetramer and its use in the dispersion of graphene

[0079] Polyethylene glycol monomethyl ether (molecular weight 2000, 6g) was dissolved in 50ml of DMF, then added toluene isocyanate of the same molar mass, reacted for 1 hour at 60 degrees, added 1.01g of aniline tetramer, and continued to react for 2 hours, using 500ml ether precipitation obtains 3.1g aniline tetramer graft polyethylene glycol (structural formula such as figure 1 shown). Weigh polyethylene glycol grafted aniline tetramer and graphene slurry (graphene content 4.5%) of equal weight to configure aqueous solutions of different concentrations, and ultrasonically disperse for 1 hour. The graphene dispersion effect is as shown in table 1. A stable dispersion can be formed when the olefin concentration is below 3 mg / ml.

[0080] Table 1. Effect of aniline tetramer grafted with polyethylene glycol to disperse graphene in water

[0081] 5mg / 10ml

Embodiment 2

[0082] Embodiment 2 aniline trimer polycaprolactone copolymer and its dispersion for graphene

[0083] Add 1.16g of aniline trimer and 50ml of dry toluene to a 100ml single-necked flask, then add 9.2g of caprolactone, and 200mg of stannous octoate, react at 120 degrees for 3 hours under a nitrogen atmosphere, and precipitate with 200ml of ethanol to obtain 8.2g Aniline trimer grafted polycaprolactone (structural formula such as figure 2 shown). Take the aniline trimer polycaprolactone copolymer of equal weight and graphene slurry (graphene content 4.5%) to configure the aqueous solution of different concentration, ultrasonic dispersion 1 hour, graphene dispersion effect is as shown in table 2, in graphite A stable dispersion can be formed when the olefin concentration is below 3 mg / ml.

[0084] Table 2. Aniline trimer polycaprolactone copolymer and its dispersion effect for graphene

[0085] 5mg / 10ml

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com