Honeycomb-structured graphene aerogel ball and production method thereof

A technology of graphene airgel and graphene airgel ball, which is applied in the field of honeycomb structure graphene airgel ball and its preparation, can solve the limitation of airgel shape, insufficient airgel strength and rebound ability , high cost of freeze vacuum drying, etc., to achieve the effect of low cost, rapid production, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

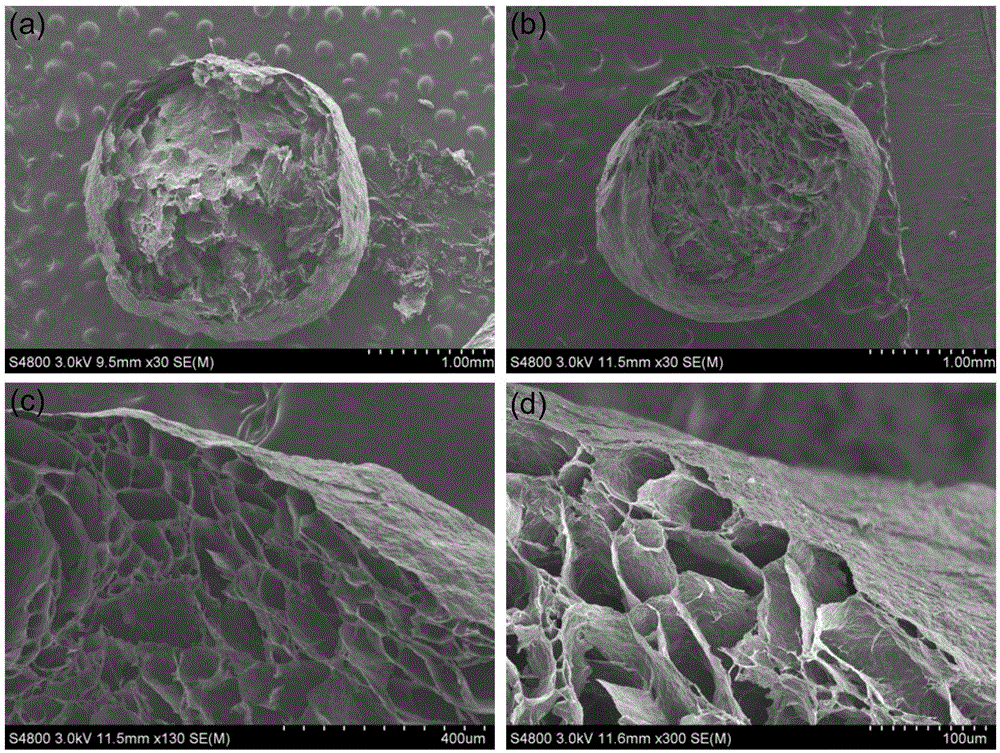

[0030] The steps of honeycomb structure graphene airgel ball and large-scale preparation method thereof are as follows:

[0031] 1) Add 1 part by weight of graphene oxide, 20-50 parts by weight of water, and 0.1-1 part by weight of ammonia water into the reactor, and stir to obtain a slurry;

[0032] 2) Squeeze the slurry through a needle with a diameter of 100-5000 microns at a speed of 0.5-2 seconds per drop, and squeeze it into a coagulation bath to obtain graphene oxide hydrogel balls;

[0033] 3) Soak the graphene oxide hydrogel balls in 20-50 parts by weight of water, add 2-5 parts by weight of a reducing agent, and put them in an oven at 60-95 degrees Celsius to react for 10 hours to obtain reduced graphene oxide hydrogel balls ;

[0034] 4) Put the reduced graphene oxide hydrogel balls in a low-temperature environment, freeze for 1-2 hours, and then thaw at room temperature;

[0035] 5) After soaking and washing in a solvent, dry in an oven at 60 degrees Celsius for ...

Embodiment 1

[0039] 1) Add 1 weight part of graphene oxide, 20 weight parts of water, 0.1 weight part of 25% mass fraction of ammonia water in the reactor, and stir to obtain a slurry;

[0040] 2) The slurry is passed through a needle with a diameter of 100 microns at a speed of 2 seconds per drop, and squeezed into a 5wt% calcium chloride coagulation bath to obtain graphene oxide hydrogel balls;

[0041] 3) Soak the graphene oxide hydrogel balls in 20 parts by weight of water, add 2 parts by weight of sodium vitamin C, and put them in an oven at 95 degrees Celsius to react for 10 hours to obtain the reduced graphene oxide hydrogel balls;

[0042] 4) Put the reduced graphene oxide hydrogel balls in an environment of -18 degrees Celsius, freeze for 1-2 hours, and then thaw at room temperature;

[0043] 5) After fully soaking and washing in water and ethanol, dry in an oven at 60 degrees Celsius for 24 hours to obtain reduced graphene oxide airgel balls;

[0044] 6) Treat the reduced graphe...

Embodiment 2

[0046] The preparation method is basically the same as that in Example 1, except that a needle with a diameter of 5000 microns is used in step 2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com