Breeding method for reducing exhaust of poultry harmful gas

A technology for harmful gases and poultry, applied to the field of poultry breeding, can solve the problems of reducing the content of harmful gases in poultry houses, unfavorable for winter insulation of poultry houses, unfavorable for healthy poultry breeding, etc. The effect of improving conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

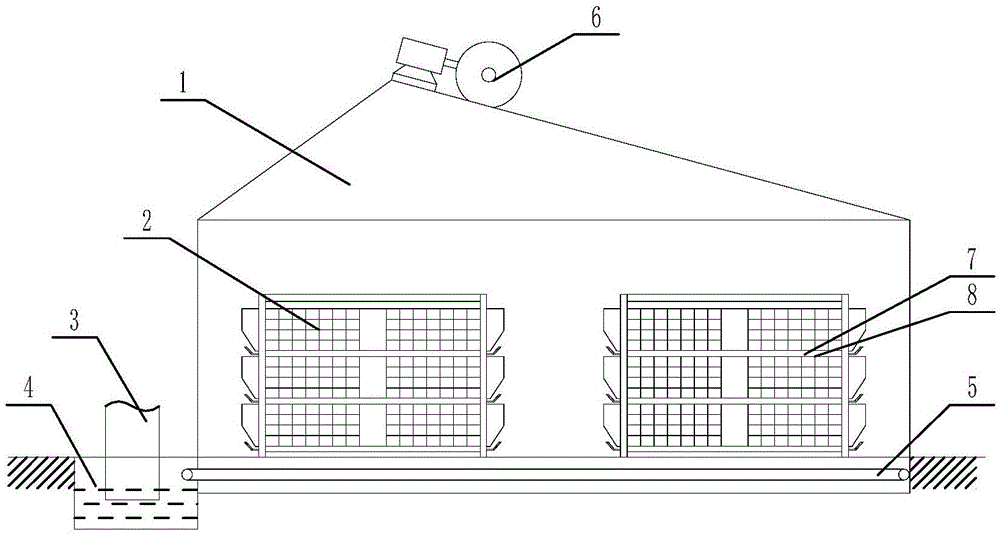

Image

Examples

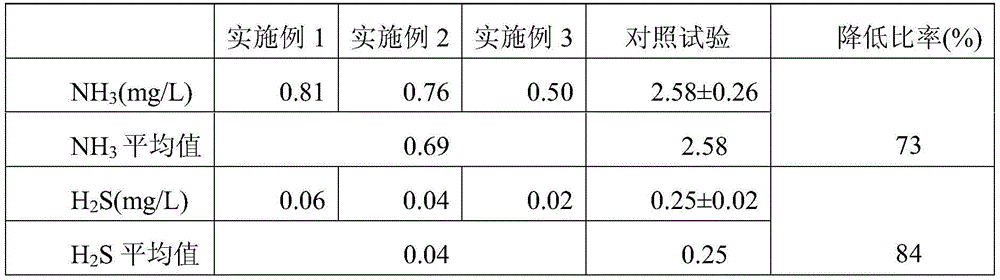

Embodiment 1

[0032] The breeding method for reducing harmful gas emissions from poultry includes the following steps:

[0033] (1) Adjustment of feed ration structure

[0034] Feed the ducks with feed supplemented with biological non-resistant feed additives;

[0035] The said biological non-antibiotic feed additive consists of the following raw materials by weight:

[0036] 28 parts of yeast cell wall polysaccharides, 23 parts of Bacillus licheniformis, 28 parts of Bacillus subtilis, 17 parts of Lactobacillus acidophilus, 17 parts of Clostridium butyricum, 5 parts of yeast selenium, 60 parts of coated slow-release acidulant, 150 parts of bran , 120 parts of stone powder and a composite enzyme preparation, the composite enzyme preparation includes 7 parts of phytase, 7 parts of glucanase, 10 parts of xylanase, and 7 parts of cellulase.

[0037] (2) Adjustment of manure removal speed

[0038] The ducks are raised in poultry breeding facilities, and the manure produced is sent to the manure collection...

Embodiment 2

[0043] The breeding method for reducing harmful gas emissions from poultry includes the following steps:

[0044] (1) Adjustment of feed ration structure

[0045] Feed the geese with feed supplemented with biological non-resistant feed additives;

[0046] The said biological non-antibiotic feed additive consists of the following raw materials by weight:

[0047] 35 parts of yeast cell wall polysaccharide, 30 parts of Bacillus licheniformis, 45 parts of Bacillus subtilis, 19 parts of Lactobacillus acidophilus, 19 parts of Clostridium butyricum, 10 parts of yeast selenium, 70 parts of coated slow-release acidulant, 160 parts of bran , 150 parts of stone powder and a composite enzyme preparation, the composite enzyme preparation includes 10 parts of phytase, 10 parts of glucanase, 15 parts of xylanase, and 10 parts of cellulase.

[0048] (2) Adjustment of manure removal speed

[0049] Geese are raised in poultry breeding facilities, and the manure produced is sent to the manure collection ...

Embodiment 3

[0054] The breeding method for reducing harmful gas emissions from poultry includes the following steps:

[0055] (1) Adjustment of feed ration structure

[0056] Feed the chickens with feed added with biological non-resistant feed additives;

[0057] The said biological non-antibiotic feed additive consists of the following raw materials by weight:

[0058] 30 parts of yeast cell wall polysaccharide, 25 parts of Bacillus licheniformis, 40 parts of Bacillus subtilis, 17.5 parts of Lactobacillus acidophilus, 17.5 parts of Clostridium butyricum, 5 parts of yeast selenium, 60 parts of coated slow-release acidulant, phytase 7.5 Parts, 7.5 parts of glucanase, 10 parts of xylanase, 7.5 parts of cellulase, 150 parts of bran, 125 parts of stone powder and a compound enzyme preparation, the compound enzyme preparation includes 8 parts of phytase, glucan Enzyme 8 parts, xylanase 12 parts, cellulase 9 parts.

[0059] (2) Adjustment of manure removal speed

[0060] Chickens are raised in poultry b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com