Preparation method of total saponins of rhizoma cimicifugae

A technology for the separation and purification of total saponins of Cimicifuga, which is applied in the field of separation and purification of total saponins of Cimicifuga, can solve the problems of large consumption of organic solvents, high risk of explosion, and long time, so as to save separation and purification time, reduce the use of organic solvents and residual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

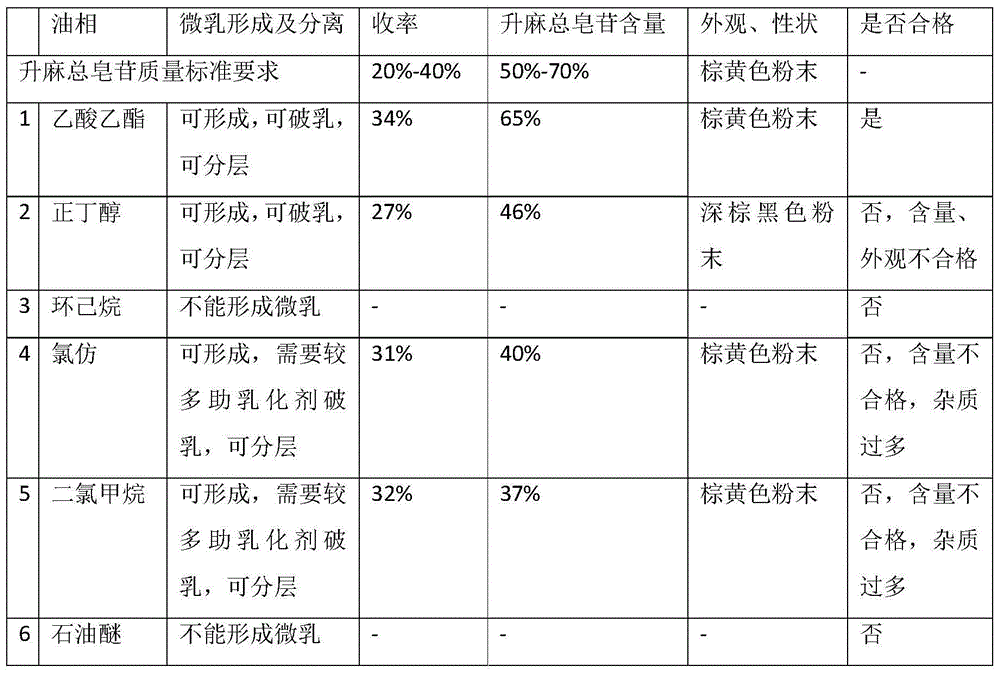

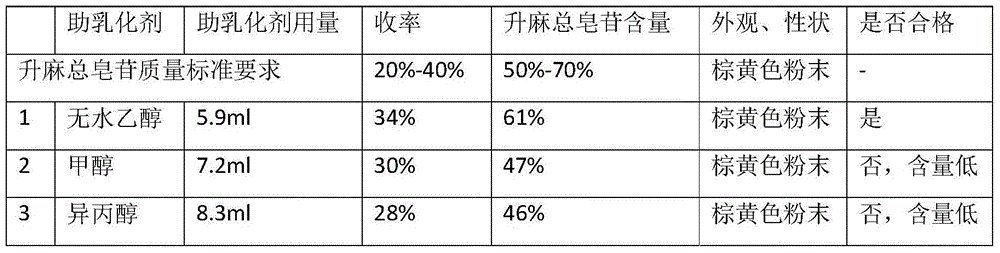

Method used

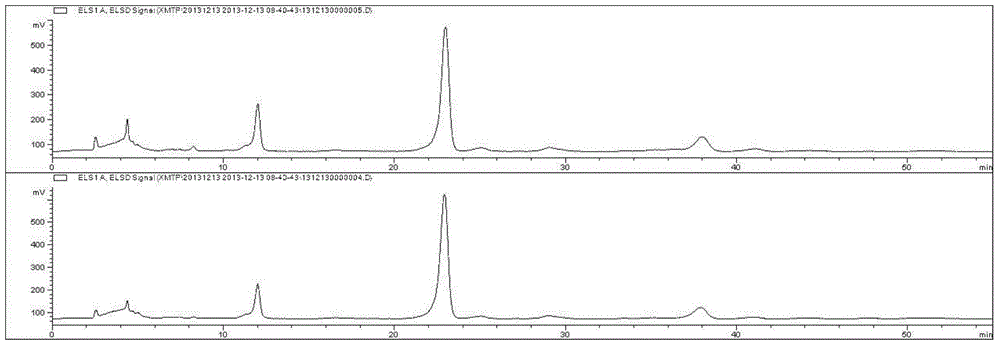

Image

Examples

Embodiment 1

[0033] Crush Cimicifuga into coarse particles, weigh 250g, heat and reflux extraction with 70% ethanol at 70°C for three times, each time with 2000g of ethanol, filter, combine the filtrates, recover ethanol, and vacuum dry at 60°C to obtain 25.7g of crude extract. Disperse the crude extract in n-hexane to degrease 3 times, use 128.5 g of n-hexane each time, filter, and recover n-hexane. Mix 424 g of water, 177.4 g of ethyl acetate, and 0.32 g of sodium lauryl sulfate, and stir to make a coarse emulsion, then add 169.28 g of absolute ethanol to make a microemulsion. The defatted crude extract was dissolved in microemulsion. After dissolving, add 0.4g sodium chloride and 0.4g sodium carbonate to the microemulsion system to break the emulsion, and let stand to separate. The water layer was discarded, the organic layer was concentrated under reduced pressure to recover the solvent, and vacuum-dried at 60° C. to obtain 8.24 g of total saponins of Cimicifuga with a yield of 32.1%....

Embodiment 2

[0035] Crush Cimicifuga into coarse particles, weigh 250g, heat and reflux extraction with 75% ethanol at 80°C for three times, each time with 2500g of ethanol, filter, combine the filtrates, recover ethanol, and vacuum dry at 60°C to obtain 27.9g of crude extract. Disperse the crude extract in n-hexane to degrease 3 times, use 111.6 g of n-hexane each time, filter, and recover n-hexane. 590 g of water, 279 g of ethyl acetate, and 0.6 g of sodium lauryl sulfate were mixed and stirred to make a coarse emulsion, and then 246.4 g of absolute ethanol was added to make a microemulsion. The defatted crude extract was dissolved in microemulsion. After dissolving, add 0.5g sodium chloride and 0.5g sodium carbonate to the microemulsion system to break the emulsion, and let stand to separate. The water layer was discarded, the organic layer was concentrated under reduced pressure to recover the solvent, and vacuum-dried at 60° C. to obtain 9.52 g of total saponins of Cimicifuga with a ...

Embodiment 3

[0037]Crush Cimicifuga into coarse particles, weigh 250g, heat and reflux extraction with 60% ethanol at 70°C for three times, each time with 1250g of ethanol, filter, combine filtrates, recover ethanol, and vacuum dry at 60°C to obtain 25.1g of crude extract. Disperse the crude extract in n-hexane to degrease 3 times, use 150.6 g of n-hexane each time, filter, and recover n-hexane. Mix 452 g of water, 390 g of ethyl acetate, and 5.6 g of poloxamer and stir to make a coarse emulsion, then add 281.9 g of absolute ethanol to make a microemulsion. The defatted crude extract was dissolved in microemulsion. After the dissolution is complete, add 0.75 g of sodium chloride and 0.75 g of sodium bicarbonate to the microemulsion system to break the emulsion, and let stand to separate. The water layer was discarded, the organic layer was concentrated under reduced pressure to recover the solvent, and vacuum-dried at 60° C. to obtain 8.35 g of total saponins of Cimicifuga with a yield of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com