Preparation method and application of metal/cuprous oxide composite nano material

A technology of composite nanomaterials and cuprous oxide, which is applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, nanotechnology, etc., can solve the undiscovered detection of hydrogen peroxide and other problems, and achieve good electrocatalytic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

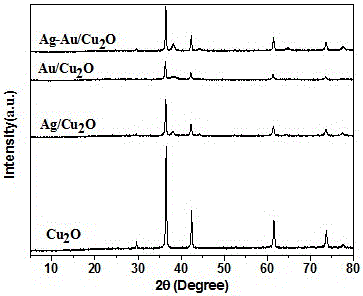

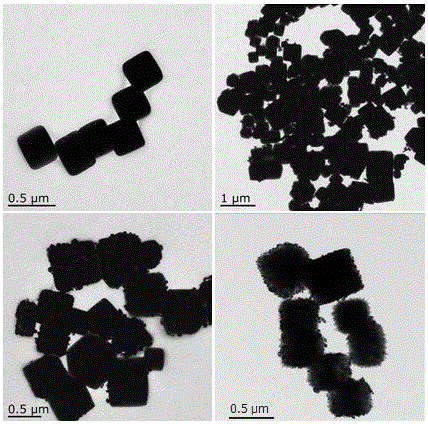

[0040] Embodiment 1: prepare the cuprous oxide Cu of cube 2 o

[0041] Cu 2 The hydrothermal synthesis method adopted in the preparation of O; 20ml, 0.009mol L -1 The ascorbic acid solution was added to 32ml, 0.391mol·L -1 In the sodium hydroxide solution, stir for 5min, then add 32ml, 0.005mol·L -1 Copper acetate monohydrate solution, stirred for 15 minutes, washed with pure water and absolute ethanol after reaction, centrifuged, and finally dried in a vacuum oven at 60°C for 12 hours to obtain cubic cuprous oxide Cu 2 O powder.

Embodiment 2

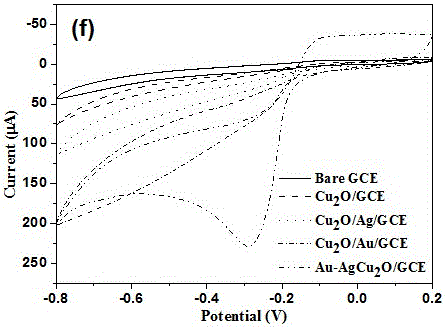

[0042] Embodiment 2: prepare 15%-15% Au-Ag / Cu 2 O composite nanomaterials

[0043] Take by weighing the Cu prepared by 0.05g embodiment 1 2 O powder was dissolved in 50ml of pure water, then ultrasonically dispersed in an ultrasonic machine with a power of 250W for 0.5h, and then 1.5ml, 0.03mol L -1 HAuCl 4 solution, stirred for 0.5h; then reduced by light for 0.5h under a tungsten lamp with a power of 500W, after the reaction, washed with pure water and absolute ethanol, centrifuged, and dried in a vacuum oven at 60°C to obtain Au and Cu 2 Au / Cu with O mass ratio of 15% 2 O composite nanomaterials.

[0044] Weigh 0.05g15%Au / Cu 2 O powder was dissolved in 50ml of pure water, then ultrasonically dispersed in an ultrasonic machine with a power of 250W for 0.5h, and then 1.5ml, 0.05mol L -1 AgNO 3 solution, stirred for 0.5h; then reduced by light for 0.5h under a tungsten lamp with a power of 500W, after the reaction, washed with pure water and absolute ethanol, centrifuge...

Embodiment 3

[0046] Embodiment 3: prepare 30%Au / Cu 2 O composite nanomaterials

[0047] Take by weighing the Cu prepared by 0.05g embodiment 1 2 O powder was dissolved in 50ml of pure water, then ultrasonically dispersed in an ultrasonic machine with a power of 250W for 0.5h, and then 3.0ml, 0.03mol L -1 HAuCl 4 solution, stirred for 0.5h; then reduced by light for 0.5h under a tungsten lamp with a power of 500W, after the reaction, washed with pure water and absolute ethanol, centrifuged, and dried in a vacuum oven at 60°C to obtain Au and Cu 2 Au / Cu with O mass ratio of 30% 2 O composite nanomaterials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com