Diamond salt fusing and tungsten plating method

A technology of diamond and diamond particles, applied in metal material coating process, heating inorganic powder coating, coating and other directions, can solve the problems of poor cleanliness of tungsten atoms, cumbersome process, weak interface bonding force, etc. The effect of high effect, low process cost and easy reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

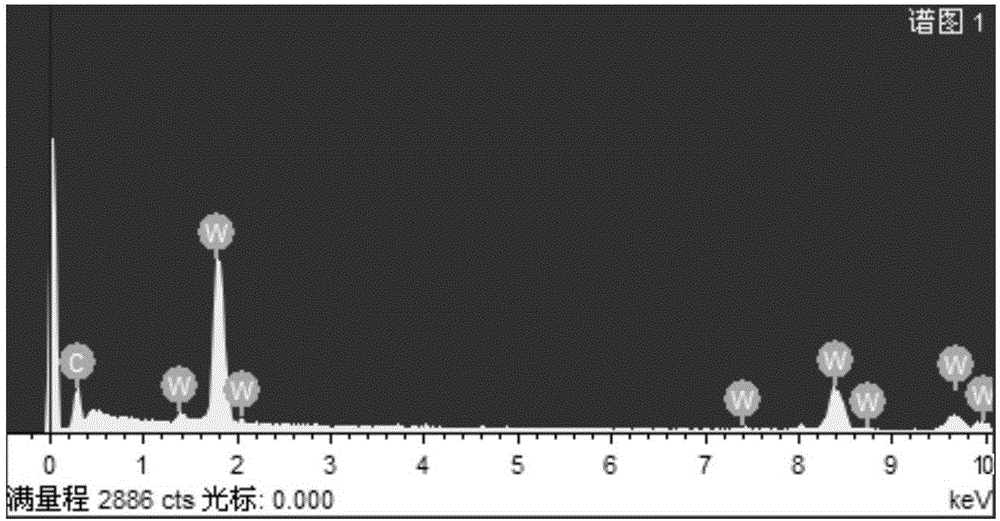

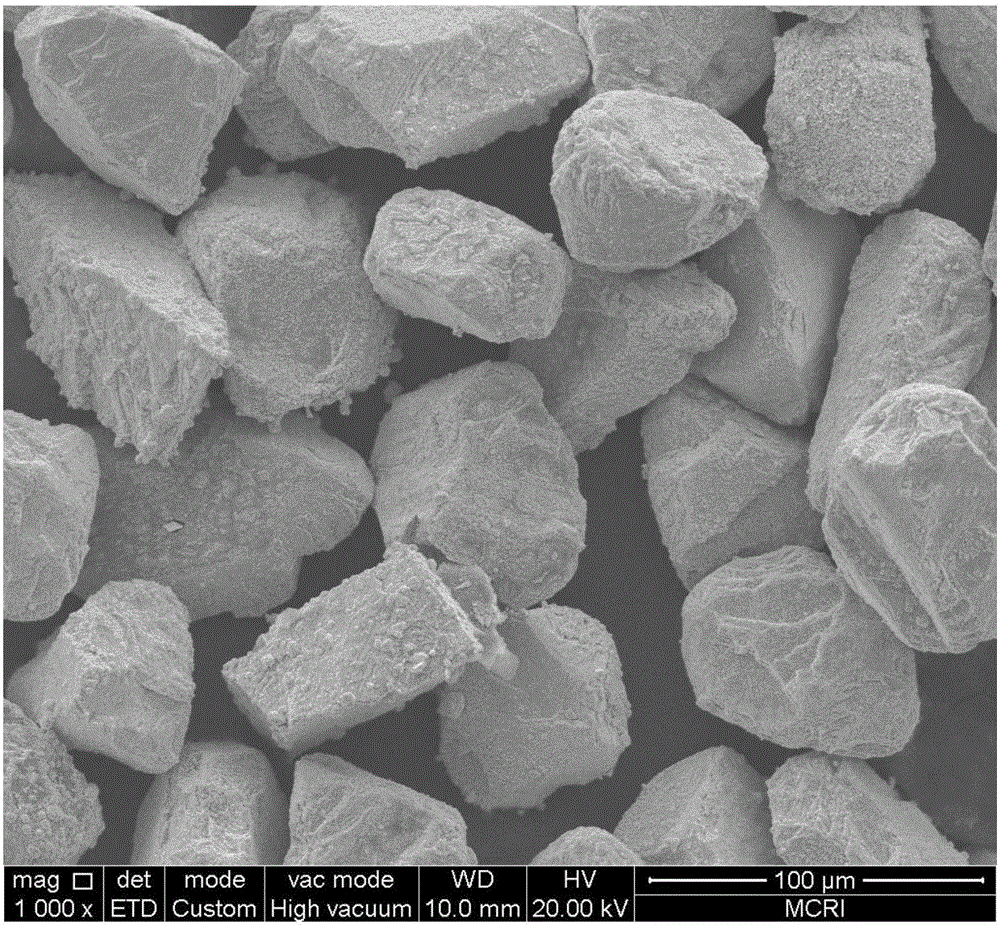

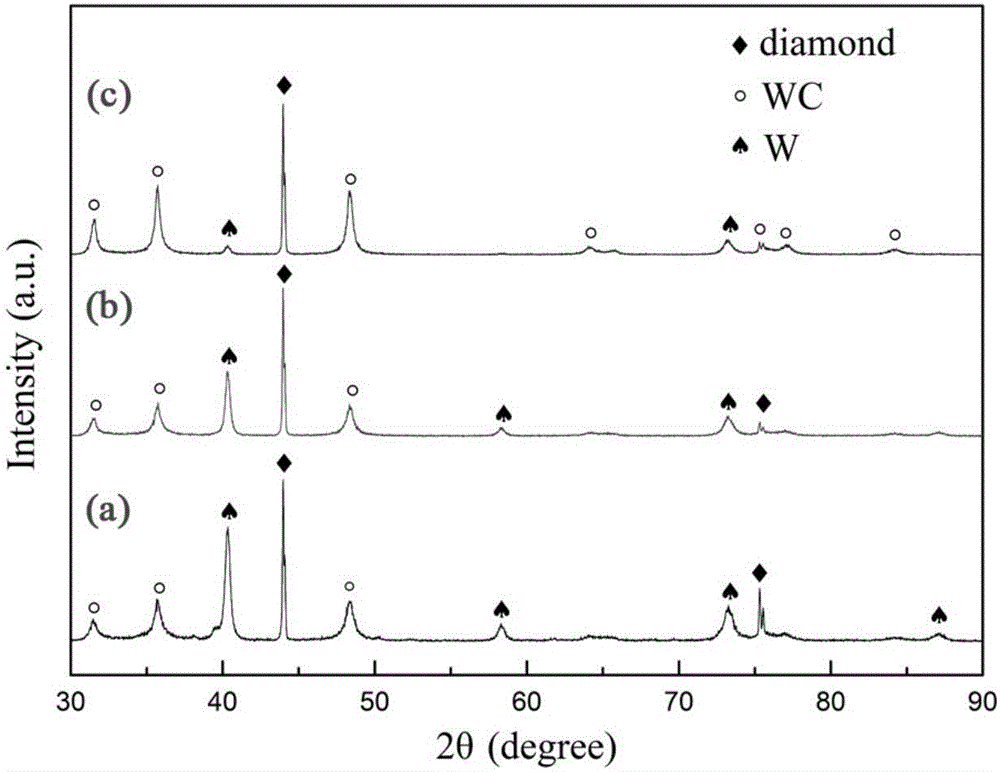

[0033] (1) The diamond particles are placed in acetone, ultrasonically cleaned, and then ultrasonically cleaned with alcohol and dried. Each cleaning time is 15 minutes; the diamond particles are commercially available with a particle size of 100 μm.

[0034] (2) Diamond, commercially available chemically pure ammonium tungstate (calculated by moles of tungsten atoms), commercially available chemically pure sodium chloride, potassium chloride salt (sodium chloride: potassium chloride = 1:1, molar ratio) Mix at a molar ratio of 20:1:20, and then place it in a ball mill tank for roller ball milling for 48 hours.

[0035] (3) Take out the ball-milled mixed powder, place it in an alumina crucible, and heat it to 1200℃ in an argon atmosphere. The temperature rise rate below 1000℃ is 20℃ / min, and the temperature rise rate at 1000-1200℃ is 5 ℃ / min, keep for 0.5h, and then cool with the furnace.

[0036] (4) The above product in the crucible after high temperature treatment is taken out and...

Embodiment 2

[0038] (1) The diamond particles are placed in acetone, ultrasonically cleaned, and then ultrasonically cleaned with alcohol and dried. Each cleaning time is 5 minutes; the diamond particles are commercially available with a particle size of 120 μm.

[0039] (2) Combine diamond, commercially available analytical pure ammonium metatungstate (calculated by moles of tungsten atoms), commercially available chemical pure sodium chloride, potassium chloride, barium chloride salt (sodium chloride, potassium chloride, chlorinated Barium = 1:1:1, molar ratio) was mixed at a molar ratio of 10:1:10, and then placed in a ball milling tank for roller ball milling for 24 hours.

[0040] (3) Take out the ball-milled mixed powder, place it in an alumina crucible, heat it to 900°C in an argon atmosphere or under vacuum, the temperature rise rate below 700°C is 20°C / min, and the temperature rises at 700-900°C The speed is 5℃ / min, the temperature is kept for 4h, and then it is cooled with the furnace...

Embodiment 3

[0043] (1) The diamond particles are placed in acetone, ultrasonically cleaned, and then ultrasonically cleaned with alcohol and dried. Each cleaning time is 10 minutes; the diamond particles are commercially available with a particle size of 10 μm.

[0044] (2) Diamond, commercially available analytical pure ammonium paratungstate (calculated by moles of tungsten atoms), commercially available chemical pure sodium chloride, sodium carbonate and sodium sulfate (sodium chloride: sodium carbonate: sodium sulfate = 1:1:1, (Molar ratio) was mixed at a molar ratio of 15:1:10, and then placed in a ball mill tank for roller ball milling for 72 hours.

[0045] (3) Take out the ball-milled mixed powder, place it in an alumina crucible, and heat it to 1000℃ in an argon atmosphere or under vacuum. The temperature rise rate below 800℃ is 20℃ / min, and the temperature rises at 800-1000℃ The rate is 5℃ / min, the temperature is kept for 2h, and then it is cooled with the furnace.

[0046] (4) Take o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com