Steel pickling solution recycling device and process based on Fenton oxidization

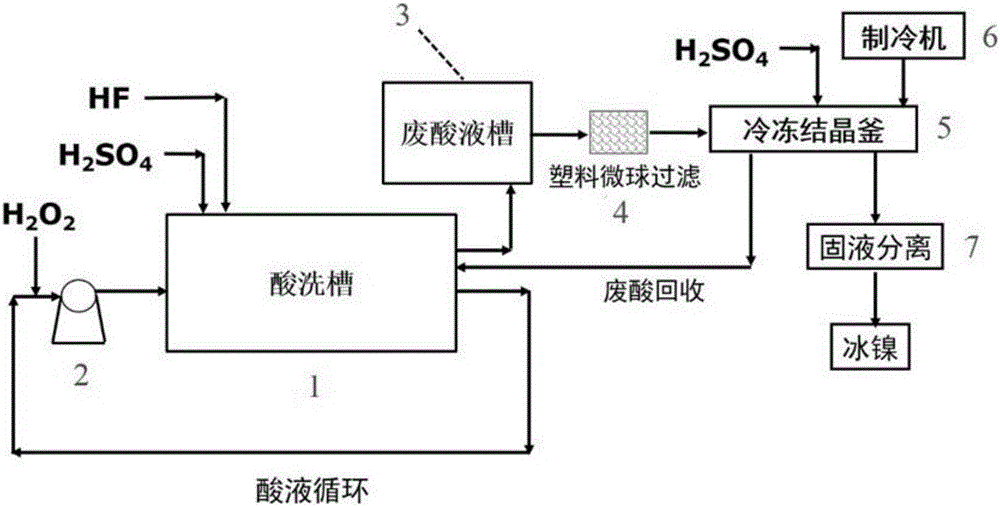

A technology for steel acid and pickling liquid, applied in the field of metal surface treatment pickling liquid, can solve the problems of high recovery cost, low recovery efficiency, content, etc., achieve good economic benefits, and realize the effect of recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: prepare 1m 3 For pickling solution, turn on the acid circulation pump and the hydrogen peroxide metering pump. After the pickling solution is evenly mixed, put untreated stainless steel into it. Stop the circulation pump, stop the pickling, discharge the pickling solution into the waste pickling tank, filter it through plastic pellets, and pump it to the crystallization tank. Add concentrated sulfuric acid to make the concentration of sulfuric acid reach 20%, turn on the refrigerator to reduce the temperature of the acid solution to 0°C, and the crystallization time is 4 hours. After solid-liquid separation in a centrifuge, about 60kg of metal sulfate crystals are obtained, and the content of nickel is about 2.2%. The pickling solution containing a small amount of metal and high sulfuric acid content is returned to the pickling tank, and the pickling solution is reconfigured in proportion.

Embodiment 2

[0023] Embodiment 2: prepare 1m 3For pickling solution, turn on the acid circulation pump and the hydrogen peroxide metering pump, put the untreated stainless steel after the pickling solution is evenly mixed, after a certain amount of continuous pickling, and turn off the pickling solution after the metal content in the pickling solution reaches 15%. Stop the circulation pump, stop the pickling, discharge the pickling solution into the waste pickling tank, filter it through plastic pellets, and pump it to the crystallization tank. Add concentrated sulfuric acid to make the concentration of sulfuric acid reach 25%, turn on the refrigerator to reduce the temperature of the acid solution to -2°C, and the crystallization time is 3 hours. After solid-liquid separation in a centrifuge, about 120kg of metal sulfate crystals are obtained, and the nickel content is about 3.5%. The pickling solution containing a small amount of metal and high sulfuric acid content is returned to the p...

Embodiment 3

[0024] Embodiment 3: prepare 1m 3 For pickling solution, turn on the acid circulation pump and the hydrogen peroxide metering pump. After the pickling solution is mixed evenly, put untreated stainless steel into it. Stop the circulation pump, stop the pickling, discharge the pickling solution into the waste pickling tank, filter it through plastic pellets, and pump it to the crystallization tank. Add concentrated sulfuric acid to make the concentration of sulfuric acid reach 20%, turn on the refrigerator to reduce the temperature of the acid solution to -4°C, and the crystallization time is 4 hours. After solid-liquid separation in a centrifuge, about 200kg of metal sulfate crystals are obtained, and the nickel content is about 4.5%. The pickling solution containing a small amount of metal and high sulfuric acid content is returned to the pickling tank, and the pickling solution is reconfigured in proportion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com