Heatproof flexible composite insulating material and preparation method thereof

A composite insulation and flexible technology, applied in the direction of organic insulators, inorganic insulators, plastic/resin/wax insulators, etc., can solve the problems that affect the wide use, soft paper, low tensile strength and elongation, and achieve reasonable structure, Highlight the effect of heat resistance and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

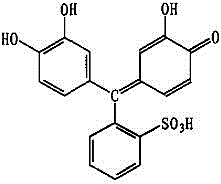

Image

Examples

Embodiment 1

[0013] Mix 100g of phenolic compound and 150g of bisphenol A cyanate monomer, stir at 90°C for 20 minutes, add 40g of pentaerythritol acrylate, 18g of dodecylbenzenesulfonic acid, and continue stirring for 40 minutes; then add 500g of epoxy resin E44, 50g m-aminoacetanilide, 14g 1-hexyne, continue stirring for 40 minutes; then cool down to 70°C, add 12g shell powder, 10g yttrium nitrate and 80g isomeric tridecanol polyoxyethylene ether, stir for 40 minutes; then stir at 110°C After 1 hour, the adhesive was obtained; after the adhesive was coated with inorganic ceramic fiber paper, it was dried in a drying tunnel at 110°C, and the polyimide film was compounded by heating and pressing the rollers to obtain a heat-resistant flexible compound. Insulation material with uniform color appearance, flat surface, no damage, no air bubbles and impurities; breakdown voltage 11KV, moisture absorption rate 0.25%, thermal adhesiveness 191°C, no delamination, no foaming, no glue flow.

Embodiment 2

[0015] Mix 100g of phenolic compound and 130g of bisphenol A cyanate monomer, stir at 90°C for 20 minutes, add 30g of pentaerythritol acrylate, 10g of dodecylbenzenesulfonic acid, and continue stirring for 40 minutes; then add 400g of epoxy resin E44, 20g m-Aminoacetanilide, 11g 1-hexyne, continue stirring for 40 minutes; then cool down to 70°C, add 10g shell powder, 8g yttrium nitrate and 50g isomeric tridecanol polyoxyethylene ether, stir for 40 minutes; then stir at 110°C After 1 hour, the adhesive was obtained; after the adhesive was coated with inorganic ceramic fiber paper, it was dried in a drying tunnel at 110°C, and the polyimide film was compounded by heating and pressing the rollers to obtain a heat-resistant flexible compound. Insulation material with uniform appearance color, flat surface, no damage, no air bubbles and impurities; breakdown voltage 11KV, moisture absorption rate 0.24%, thermal adhesiveness 192°C, no delamination, no foaming, no glue flow.

Embodiment 3

[0017] Mix 100g of phenolic compound and 140g of bisphenol A cyanate monomer, stir at 90°C for 20 minutes, add 35g of pentaerythritol acrylate, 15g of dodecylbenzenesulfonic acid, and continue stirring for 40 minutes; then add 450g of epoxy resin E44, 35g m-aminoacetanilide, 12g 1-hexyne, continue stirring for 40 minutes; then cool down to 70°C, add 11g shell powder, 9g yttrium nitrate and 65g isomeric tridecanol polyoxyethylene ether, stir for 40 minutes; then stir at 110°C After 1 hour, the adhesive was obtained; after the adhesive was coated with inorganic ceramic fiber paper, it was dried in a drying tunnel at 110°C, and the polyimide film was compounded by heating and pressing the rollers to obtain a heat-resistant flexible compound. Insulation material with uniform color appearance, flat surface, no damage, no air bubbles and impurities; breakdown voltage 11KV, moisture absorption rate 0.21%, thermal adhesiveness 194°C, no delamination, no foaming, no glue flow.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com