Method for preparing absorption layer of CZTSSe thin film solar cell by co-evaporation

A thin-film solar cell, copper-zinc-tin-sulfur-selenium technology, which is used in circuits, electrical components, and final product manufacturing, can solve problems such as loss of Sn element, loss of Zn element, and difficulty in film composition, and achieve the effect of inhibiting re-evaporation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

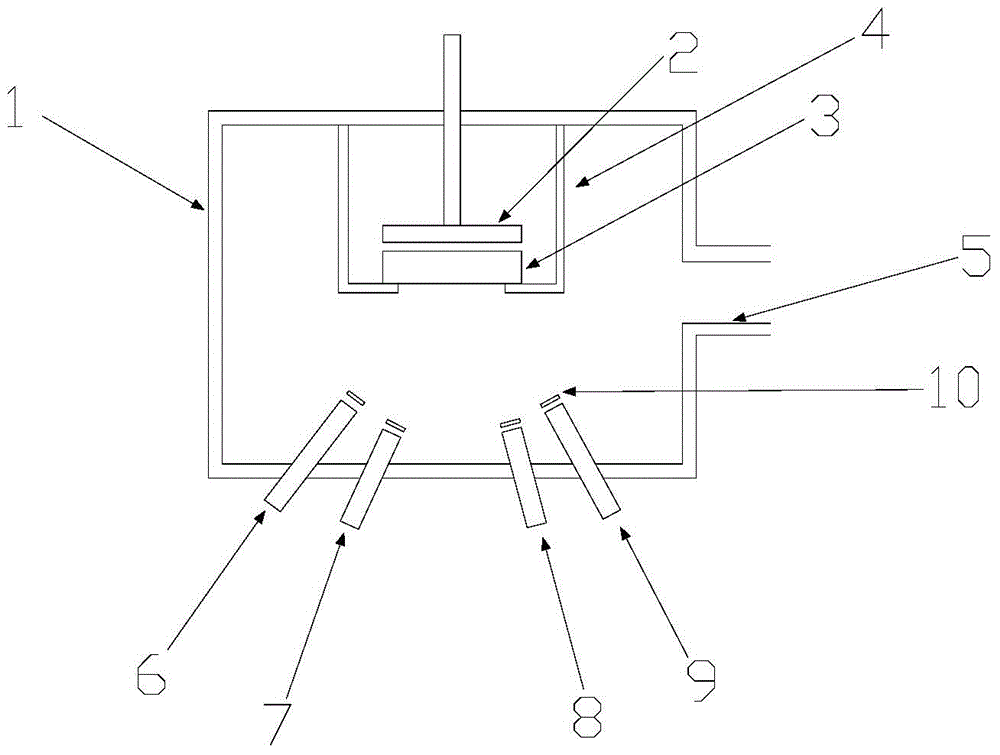

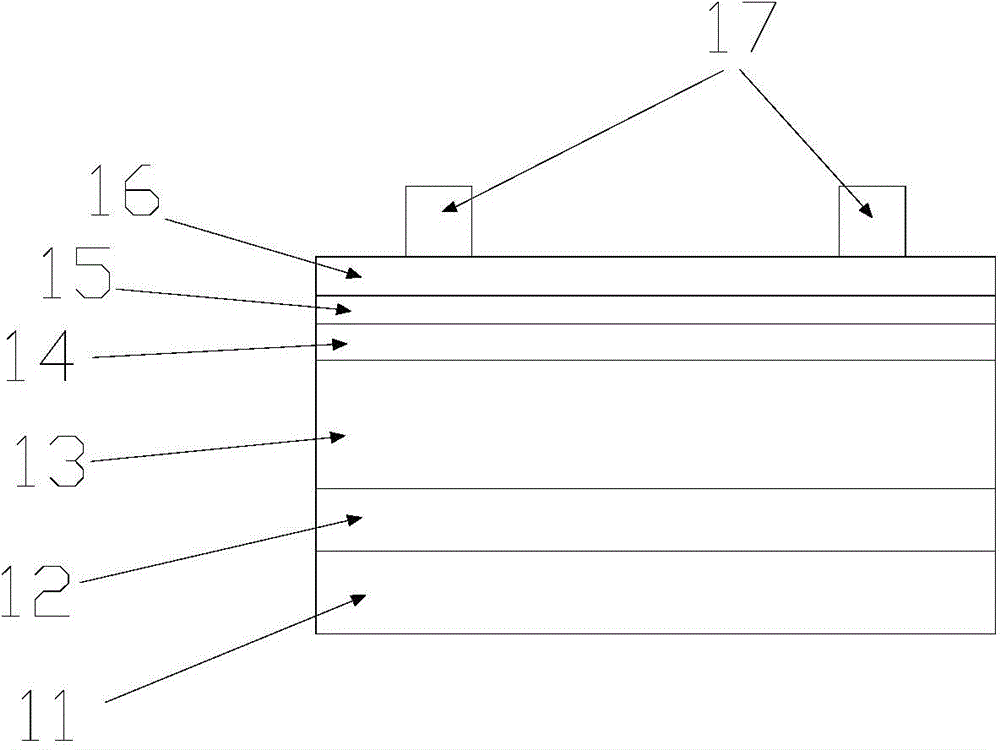

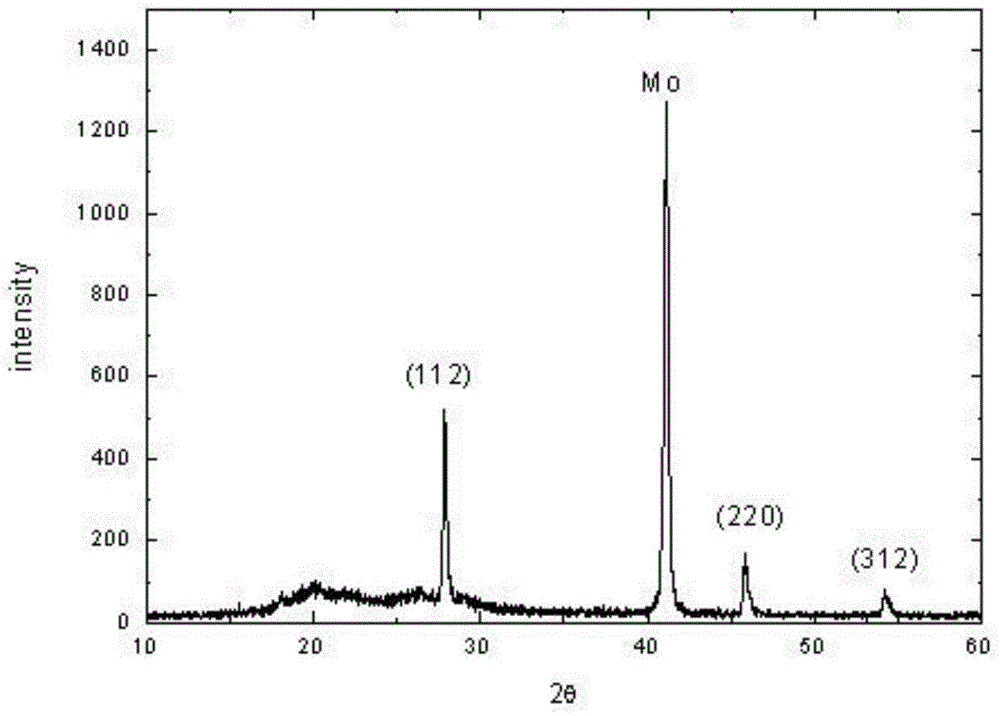

[0029] A method for preparing copper-zinc-tin-sulfur-selenium thin-film solar cell absorber layer by co-evaporation, using soda-lime glass as the substrate 11, and depositing a 1 μm thick Mo back electrode 12 on the substrate by magnetron sputtering; Copper-zinc-tin-sulfur-selenium absorbing layer is prepared on the electrode; the preparation process of the copper-zinc-tin-sulfur-selenium absorbing layer is: (1) the substrate of Mo plating is placed in the sample rack 4 of co-evaporation equipment chamber, and sample rack can be rotation; a substrate heating device 2 is placed above the substrate; Cu evaporation source 6, ZnS evaporation source 7, Sn evaporation source 8, and Se evaporation source 9 are evenly distributed under the evaporation chamber, and the inside of the evaporation source is equipped with a thermocouple for Monitor the evaporation temperature, and place evaporation source baffles 10 between the substrate and Cu, ZnS, Sn, Se evaporation sources; (2) Vacuumiz...

Embodiment 2

[0032] A stainless steel foil with a thickness of 40 μm was used as the substrate, and the other conditions were the same as in Example 1 to prepare a copper-zinc-tin-sulfur-selenium thin-film solar cell with a stainless steel substrate structure.

Embodiment 3

[0034] A titanium foil with a thickness of 40 μm was used as the substrate, and other conditions were the same as in Example 1 to prepare a copper-zinc-tin-sulfur-selenium thin-film solar cell with a titanium substrate structure.

[0035] This embodiment can effectively suppress the re-evaporation of the Zn element, obtain a copper-zinc-tin-sulfur-selenium film material with a composition close to the stoichiometric ratio, and promote the full diffusion and combination of elements in the film, thereby improving the crystal quality of the film and improving the copper-zinc-tin-sulfur selenium film material. Positive effects such as uniformity and optoelectronic properties of sulfur-selenide materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com