A kind of preparation method of recycled non-woven fiber/plastic composite board

A technology of recycled fibers and non-woven fabrics, applied in the field of building materials, can solve problems such as air pollution, land occupation, and waste of resources, and achieve the effects of easy construction, reduced formaldehyde emissions, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The preparation method of the regenerated non-woven fabric fiber / PP composite board of the present embodiment, the steps are as follows:

[0020] (1) Cleaning: Waste non-woven fabrics were washed with high-pressure water (15 MPa), detergent (mainly composed of sodium alkylsulfonate and sodium fatty alcohol ether sulfate), dilute alkali (2 mol / L), dilute acid (2 mol / L), distilled water, and dried at 130°C for 2 hours;

[0021] (2) Fiber opening: the above-mentioned clean non-woven fabric is opened to obtain recycled short fibers;

[0022] (3) Air-laid: Air-laid regenerated short fibers to form a three-dimensional fiber web;

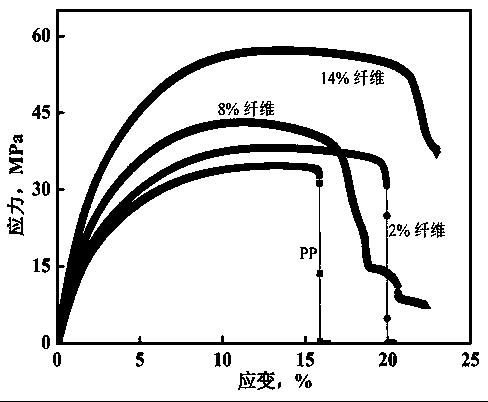

[0023] (4) Hot pressing molding: spread a certain amount of polypropylene pellets (melting point 167 °C) evenly on the above-mentioned three-dimensional fiber net, and hot press at 180 °C and 10 MPa pressure for 10 min to obtain a composite material with good mechanical properties. High-performance recycled non-woven fiber / PP composite board. Amo...

Embodiment 2

[0026] The preparation method of the regenerated non-woven fiber / HDPE composite board of the present embodiment, the steps are as follows:

[0027] (1) Cleaning: Waste non-woven fabrics were washed with high-pressure water (10 MPa), detergent (mainly composed of sodium alkyl sulfonate and sodium fatty alcohol ether sulfate), dilute alkali (5 mol / L), dilute acid (5 mol / L), distilled water, and dried at 130°C for 2 h;

[0028] (2) Fiber opening: the above-mentioned clean non-woven fabric is opened to obtain recycled short fibers;

[0029] (3) Air-laid: Air-laid regenerated short fibers to form a three-dimensional fiber web;

[0030] (4) Hot pressing molding: A certain amount of HDPE pellets (melting point 135°C) is evenly spread on the above-mentioned three-dimensional fiber net, and hot-pressed at 165°C and 7 MPa pressure for 15 minutes to obtain a composite with good mechanical properties. The recycled non-woven fiber / HDPE composite board, in which the quality of the three-d...

Embodiment 3

[0032] The preparation method of the regenerated non-woven fiber / LLDPE composite board of the present embodiment, the steps are as follows:

[0033] (1) Cleaning: waste non-woven fabrics were washed with high-pressure water (20 MPa), detergent (mainly composed of sodium alkylsulfonate and sodium fatty alcohol ether sulfate), dilute alkali (3 mol / L), dilute acid (3 mol / L), distilled water, and dried at 130°C for 2 h;

[0034] (2) Fiber opening: the above-mentioned clean non-woven fabric is opened to obtain recycled short fibers;

[0035] (3) Air-laid: Air-laid regenerated short fibers to form a three-dimensional fiber web;

[0036] (4) Hot pressing molding: spread a certain amount of LLDPE pellets (melting point of 123°C) evenly on the above-mentioned three-dimensional fiber net, and hot press at 143°C and 5 MPa pressure for 8 minutes to obtain a mold with good mechanical properties. The recycled non-woven fiber / LLDPE composite board, in which the quality of the three-dimensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com