Method for preparing ultramicro boron-carbide powder by using waste slurry from fine grinding of sapphire

A fine grinding and boron carbide technology, which is applied in the field of preparing boron carbide ultrafine powder, can solve the problems of increasing sapphire processing cost, environmental protection, impurity increase, unusable and other problems, so as to avoid multi-stage crushing process, less pollution and reduce processing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

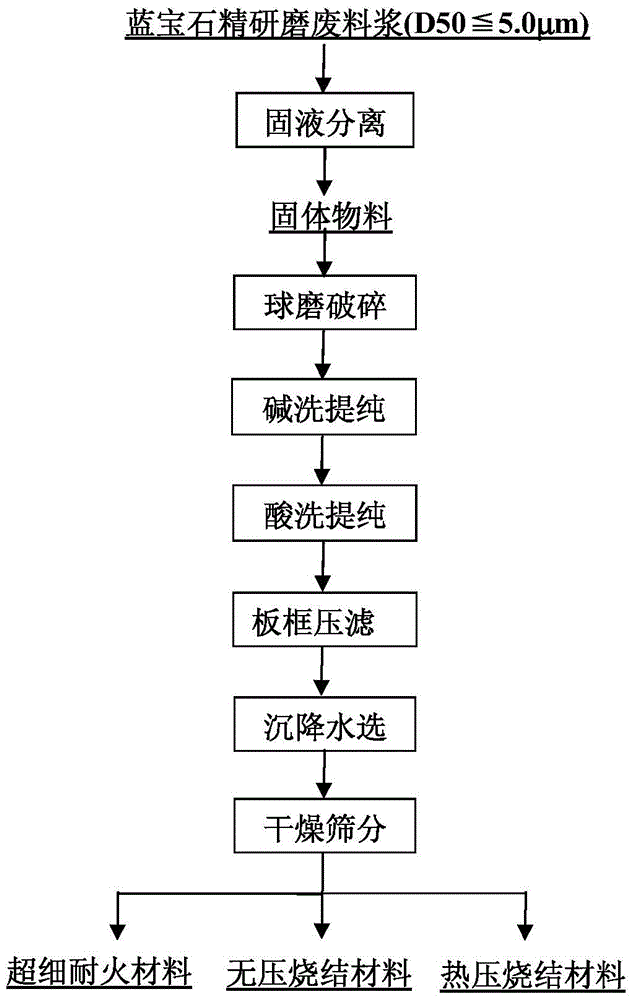

[0039] The method for preparing boron carbide superfine powder with sapphire fine grinding waste slurry comprises the following steps:

[0040] Step 1, solid-liquid separation:

[0041] The sapphire waste slurry is finely ground for solid-liquid separation to obtain solid materials, wherein:

[0042] The solid-liquid separation adopts the centrifugation method, and the rotating speed of the centrifugation method is 2000r / min; in the obtained solid material, B 4 The particle size range of C is 0.1~15μm, D50≤5.0μm; the composition is by mass percentage: B 4 C: 85wt%, Fe: 5wt%, Al 2 o 3 : 10wt%;

[0043] Step 2, ball mill crushing:

[0044] The solid material is crushed by ball milling with water as the medium to obtain the crushed material with a particle size range of 0.1 to 5 μm, wherein: the ball milling parameters are: the mass ratio of solid material: water: steel ball is 1:2:2, and the diameter of the steel ball is 3~5mm, ball milling time is 5h;

[0045] Step 3, al...

Embodiment 2

[0063] The method for preparing boron carbide superfine powder with sapphire fine grinding waste slurry comprises the following steps:

[0064] Step 1, solid-liquid separation:

[0065] The sapphire waste slurry is finely ground for solid-liquid separation to obtain solid materials, wherein:

[0066] The solid-liquid separation adopts the gravity sedimentation method, and the sedimentation time of the gravity sedimentation method is 16h; in the obtained solid, B 4 The particle size range of C is 0.1~15μm, D50≤5.0μm; the composition is by mass percentage: B 4 C: 95wt%, Fe: 1wt%, Al 2 o 3 : 4wt%;

[0067] Step 2, ball mill crushing:

[0068] The solid material is crushed by ball milling with water as the medium to obtain the crushed material with a particle size range of 0.1 to 5 μm, wherein: the ball milling parameters are: the mass ratio of solid material: water: steel ball is 1:0.4:4, and the diameter of the steel ball is 2~5mm, ball milling time is 3h;

[0069] Step 3...

Embodiment 3

[0087] The method for preparing boron carbide superfine powder with sapphire fine grinding waste slurry comprises the following steps:

[0088] Step 1, solid-liquid separation:

[0089] The sapphire waste slurry is finely ground for solid-liquid separation to obtain solid materials, wherein:

[0090] The solid-liquid separation adopts the centrifugation method, and the rotating speed of the centrifugation method is 8000r / r / min; in the obtained solid material, B 4 The particle size range of C is 0.1~15μm, D50≤5.0μm; the composition is by mass percentage: B 4 C: 90wt%, Fe: 4wt%, Al 2 o 3 : 6wt%;

[0091] Step 2, ball mill crushing:

[0092] The solid material is crushed by ball milling with water as the medium to obtain a crushed material with a particle size range of 0.1 to 5 μm, wherein: the ball milling parameters are: the mass ratio of solid material: water: steel ball is 1:3:0.3, and the diameter of the steel ball is 6~10mm, ball milling time is 7h;

[0093] Step 3, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com