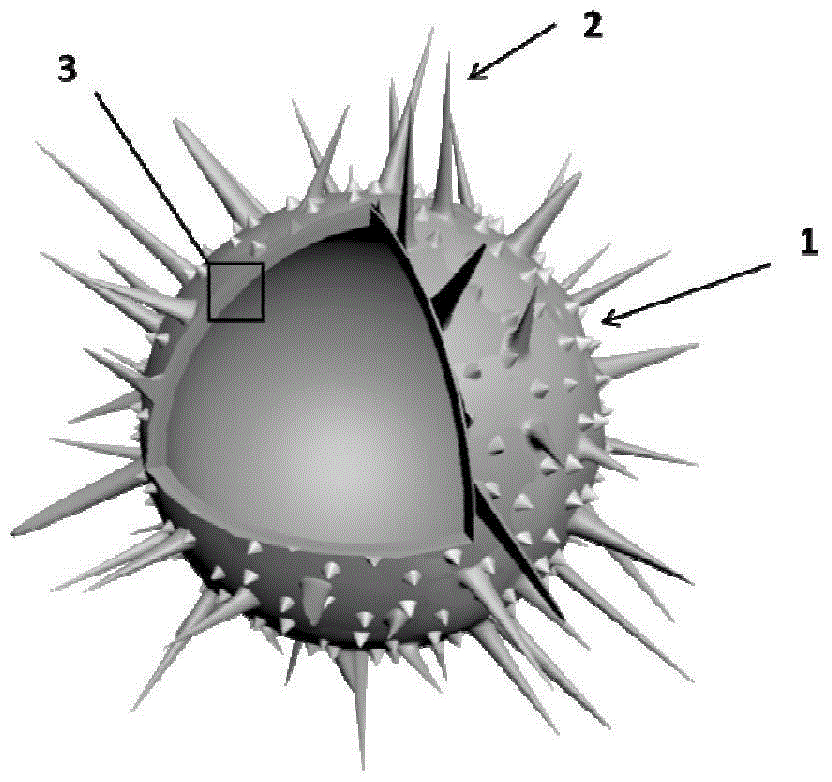

Virus structure-imitated high-polymer vesica as well as preparation method and application thereof

A polymer vesicle and polymer solution technology, which is applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, can solve the problems that polymer vesicles have not been publicly reported, and achieve High production efficiency, simple and feasible process, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

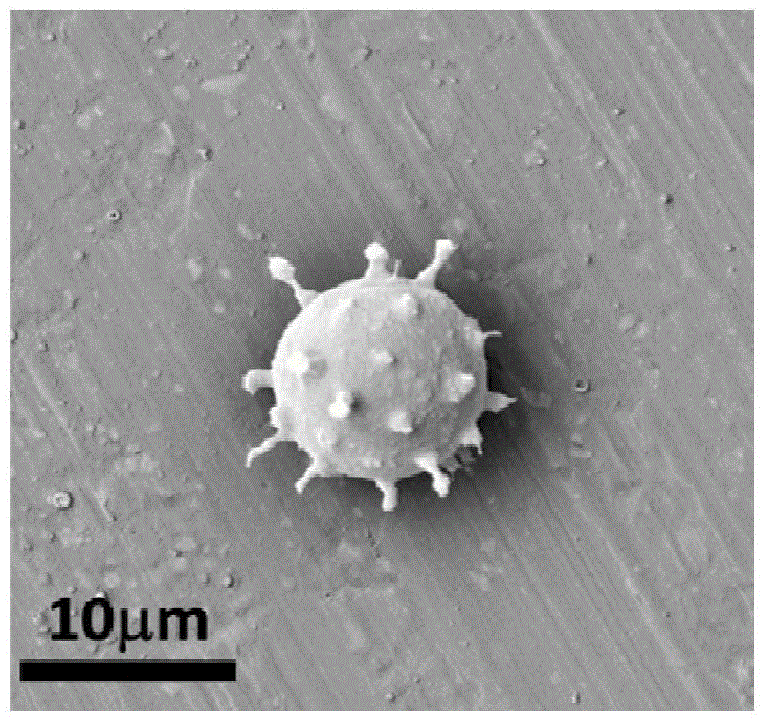

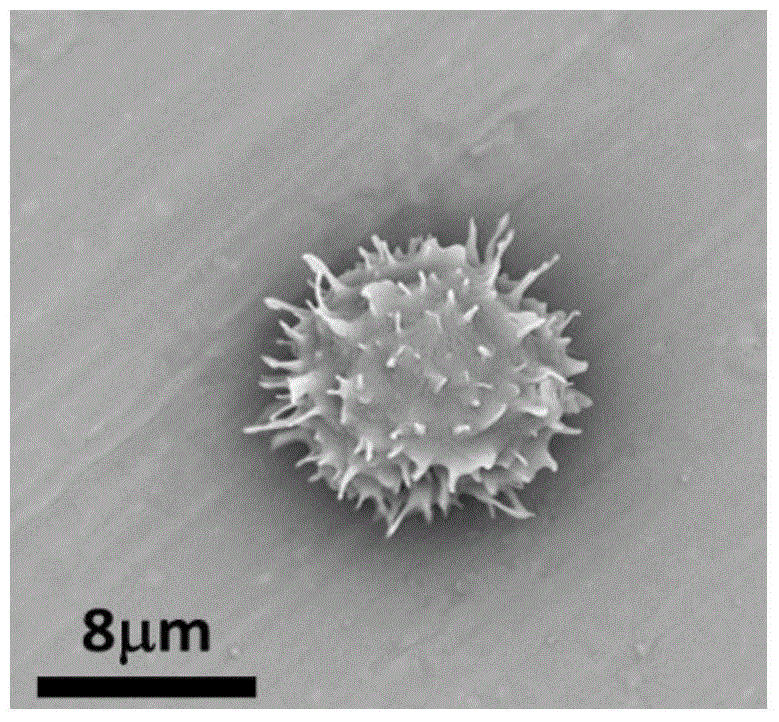

Image

Examples

Embodiment 1

[0057] (1) Take PEG (PEG-5000, that is, PEG with a molecular weight of 5000Da), lactide (the molar ratio of PEG to lactide is 1:0.3) and stannous octoate (the amount of stannous octoate is PEG-5000 quality 0.1%) were added together to toluene, stirred at 120°C for 18h at a constant temperature under a nitrogen atmosphere (350r / min), then precipitated in excess cold ether, filtered with suction, and vacuum-dried at 55°C for 4h to obtain PEG 5000 -b-PLA 2000 block copolymers;

[0058] (2) Change the addition amount of PEG and lactide, that is, the molar ratio of PEG-5000 and lactide is 1:3 to obtain PEG 5000 -b-PLA 45000 block copolymers;

[0059] (3) Weigh 0.05g block copolymer PEG 5000 -b-PLA 2000 and 0.05 g block copolymer PEG 5000 -b-PLA 45000 Added in 1g of DCM, mechanically stirred for 6min (stirring speed is 750r / min), to obtain a polymer solution (the amount of the block copolymer is 10wt% of the organic solvent);

[0060] (4) Add the polymer solution to 6.6 g of...

Embodiment 2

[0062] (1) Dissolve PEG-5000 in toluene, add stannous octoate (the amount of stannous octoate is 0.1% of the mass of PEG-5000), under the protection of argon, slowly add caprolactone monomer (PEG-5000 and caprolactone The molar ratio is 1:1), stirred at 110°C for 48h at a constant temperature (300r / min), and the toluene was removed by rotary evaporation under reduced pressure, precipitated in excess cold ether, filtered by suction, and vacuum-dried at 55°C for 4h to obtain PEG 5000 -b-PCL 5000 block copolymers;

[0063] (2) Take PEG (PEG-5000), lactide (the molar ratio of PEG-5000 and lactide is 1:5) and stannous octoate (the amount of stannous octoate is 0.1% of the mass of PEG-5000) and add them together into toluene, stirred at 120°C for 18h under a nitrogen atmosphere (350r / min), then precipitated in excess cold ether, filtered with suction, and dried in vacuum at 55°C for 4h to obtain PEG 5000 -b-PLA 95000 block copolymers;

[0064] (3) Weigh 0.05g block copolymer PEG...

Embodiment 3

[0067] (1) Dissolve PEG-5000 in toluene, add stannous octoate (the amount of stannous octoate is 0.1% of the quality of PEG-5000), under the protection of argon, slowly add caprolactone monomer (PEG and caprolactone molar ratio 1:0.4), stirred at 110°C for 48h (rotating speed: 300r / min), removed toluene by rotary evaporation under reduced pressure, precipitated in excess cold ether, filtered, and dried in vacuum at 55°C for 4h to obtain PEG 5000 -b-PCL 2500 block copolymers;

[0068] (2) Change the addition of PEG and caprolactone, that is, the mol ratio of PEG and caprolactone is 1: 3 to obtain PEG 5000 -b-PCL 45000 block copolymers;

[0069] (3) Weigh 0.05g block copolymer PEG 5000 -b-PCL 2500 and 0.05 g block copolymer PEG 5000 -b-PCL 45000 Add to 1g of DCM / petroleum ether (mass ratio 2:3), mechanically stir for 20min (stirring speed is 200r / min), to obtain a polymer solution (the amount of block copolymer is 10wt% of the organic solvent);

[0070](4) Vacuum-dry the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com