Technology for recycling nickel from hydrogenation tail oil of slurry bed

A technology of hydrogenated tail oil and suspended bed is applied in the direction of improving process efficiency, which can solve the problems of low metal recovery rate and secondary pollution, and achieve the effects of high purity, high recovery rate and large processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

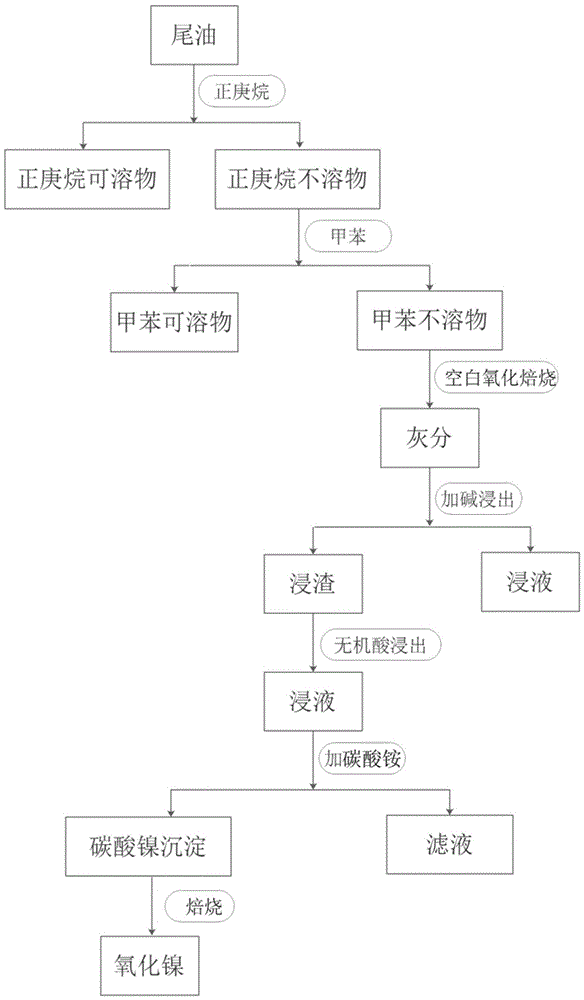

Method used

Image

Examples

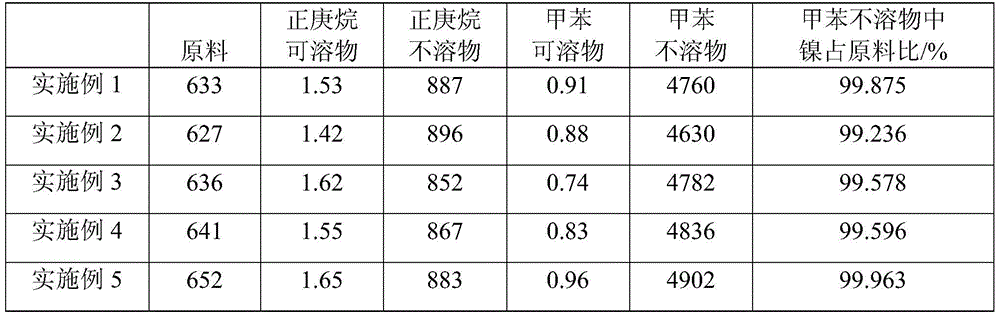

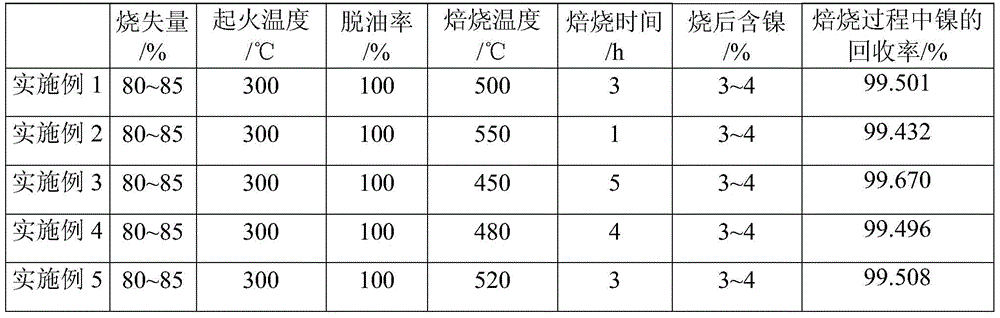

Embodiment 1

[0037] The present embodiment provides a process for recovering nickel in the suspension bed hydrogenation tail oil, comprising the following steps:

[0038] (1) Take the suspended bed hydrogenation tail oil and pulverize it, pass through a 20-mesh sieve, dry, add n-heptane, the addition of n-heptane is 4ml / g, and obtain n-heptane solubles and n-heptane insolubles;

[0039] (2) Get n-heptane insoluble matter, add toluene, the add-on of toluene is 4ml / g, obtain toluene soluble matter and toluene insoluble matter;

[0040] (3) Take the toluene insoluble matter and carry out blank oxidation roasting at a temperature of 500°C and a roasting time of 3 hours;

[0041] (4) Add 3mol / L sodium carbonate solution to the roasted ash for secondary leaching, the leaching temperature is 70°C, and the leaching time is 60min each time. The ratio is 3:1, and nickel slag is obtained by separation;

[0042] (5) Add 3mol / L hydrochloric acid to nickel slag for acid leaching. The acid leaching tem...

Embodiment 2

[0044] The present embodiment provides a process for recovering nickel in the suspension bed hydrogenation tail oil, comprising the following steps:

[0045] (1) Take the suspended bed hydrogenation tail oil and pulverize it, pass through a 20-mesh sieve, dry, add n-heptane, the addition of n-heptane is 3ml / g, and obtain n-heptane soluble matter and n-heptane insoluble matter;

[0046] (2) get n-heptane insoluble matter, add toluene, the add-on of toluene is 5ml / g, obtain toluene soluble matter and toluene insoluble matter;

[0047] (3) Take the toluene insoluble matter and carry out blank oxidation roasting at a temperature of 550°C and a roasting time of 1 h;

[0048] (4) Add 2mol / L sodium carbonate solution to the roasted ash for secondary leaching, the leaching temperature is 100°C, and the leaching time is 90min each time. The ratio is 4:1, and nickel slag is obtained by separation;

[0049] (5) Add 4mol / L sulfuric acid to nickel slag for acid leaching, the acid leachin...

Embodiment 3

[0051] The present embodiment provides a process for recovering nickel in the suspension bed hydrogenation tail oil, comprising the following steps:

[0052] (1) Take the suspended bed hydrogenation tail oil and pulverize it, pass through a 20-mesh sieve, dry, add n-heptane, the addition of n-heptane is 5ml / g, and obtain n-heptane solubles and n-heptane insolubles;

[0053] (2) Get n-heptane insoluble matter, add toluene, the add-on of toluene is 4ml / g, obtain toluene soluble matter and toluene insoluble matter;

[0054] (3) Take the toluene insoluble matter and carry out blank oxidation roasting at a temperature of 450°C and a roasting time of 5 hours;

[0055] (4) Add 4mol / L sodium carbonate solution to the roasted ash for secondary leaching, the leaching temperature is 40°C, and the leaching time is 60min each time. The ratio is 2:1, and nickel slag is obtained by separation;

[0056] (5) Add 1mol / L nitric acid to nickel slag for acid leaching, the acid leaching temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com