Papermaking auxiliary agent composition

A technology of papermaking auxiliary agent and composition, which is applied in the field of papermaking auxiliary agent composition, can solve the problems of poor comprehensive performance and high cost, and achieve the effects of improving performance, improving tensile strength and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

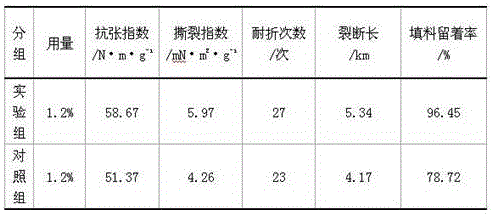

Examples

Embodiment 1

[0028] Example 1 A papermaking auxiliary composition prepared from the following raw materials, all in parts by weight (3.5kg / part): 12 parts of hemicellulose, 20 parts of nano-titanium dioxide, 10 parts of zeolite, and 3 parts of polyethylene glycol , 1 part of magnesium stearate, 2 parts of chlorinated paraffin, 1 part of nonylphenol polyoxyethylene ether, 2 parts of high-carbon alcohol fatty acid ester complex, 1 part of hydroquinone, 2 parts of microcrystalline wax, carboxamide 1 part, 1 part of disodium hydrogen phosphate, 1 part of mannitol.

[0029] A preparation method of a papermaking auxiliary composition is:

[0030] (1) Grind zeolite into fine powder, pass through a 110-mesh sieve, and set aside;

[0031] (2) Mix hemicellulose, carbonamide and nano-titanium dioxide, place in a reaction kettle with a stirring device and a heating system, add 1.8 times the amount of water, raise the temperature to 65°C, adjust the speed to 800rpm, and stir for 24 minutes , then adj...

Embodiment 2

[0034] Example 2 A papermaking auxiliary composition prepared from the following raw materials, all in parts by weight (1.5kg / part): 20 parts of hemicellulose, 30 parts of nano-titanium dioxide, 14 parts of zeolite, and 8 parts of polyethylene glycol , 5 parts of magnesium stearate, 6 parts of chlorinated paraffin, 3 parts of nonylphenol polyoxyethylene ether, 3 parts of high-carbon alcohol fatty acid ester complex, 2 parts of hydroquinone, 5 parts of microcrystalline wax, carboxamide 2 parts, 4 parts of disodium hydrogen phosphate, 5 parts of mannitol.

[0035] A preparation method of a papermaking auxiliary composition is:

[0036] (1) Zeolite is ground into fine powder, passed through a 140-mesh sieve, and set aside;

[0037] (2) Mix hemicellulose, carbonamide and nano-titanium dioxide, place in a reaction kettle with a stirring device and a heating system, add 2.6 times the amount of water, raise the temperature to 85°C, adjust the speed to 1400rpm, and stir for 46 minute...

Embodiment 3

[0040] Example 3 A papermaking auxiliary composition prepared from the following raw materials, all in parts by weight (3kg / part): 14 parts of hemicellulose, 23 parts of nano-titanium dioxide, 11 parts of zeolite, 4 parts of polyethylene glycol, 2 parts of magnesium stearate, 3 parts of chlorinated paraffin, 1.5 parts of nonylphenol polyoxyethylene ether, 2.3 parts of high-carbon alcohol fatty acid ester complex, 1.2 parts of hydroquinone, 3 parts of microcrystalline wax, 1.2 parts of carboxamide 2 parts, 2 parts of disodium hydrogen phosphate, 2 parts of mannitol.

[0041] A preparation method of a papermaking auxiliary composition is:

[0042] (1) Zeolite is ground into fine powder, passed through a 120-mesh sieve, and set aside;

[0043] (2) Mix hemicellulose, carbonamide and nano-titanium dioxide, place it in a reaction kettle with a stirring device and a heating system, add 2 times the amount of water, raise the temperature to 70°C, adjust the speed to 950rpm, and stir f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com