A kind of adsorption inhibitor of carboxybetaine surfactant

A carboxybetaine and surfactant technology, applied in the field of colloid and interface chemistry, can solve the problems of high adsorption rock surface and other problems, and achieve the effect of inhibiting adsorption, excellent adsorption inhibitor, and good adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

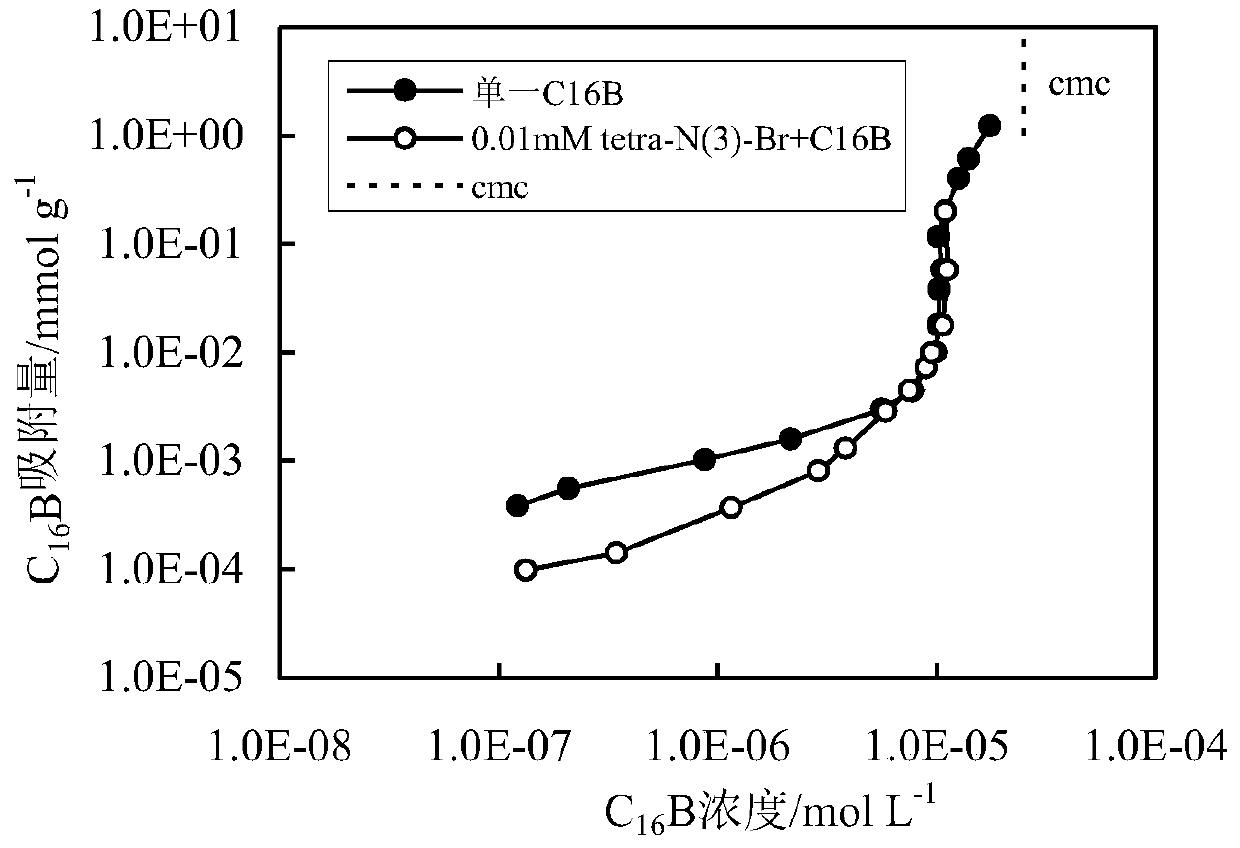

[0021] Embodiment 1, tetrameric quaternary ammonium salt inhibits C 16 Adsorption of B at the nanosilica / water interface. A compound in the oligomeric quaternary ammonium salt was used for testing, the compound n=3, m=2, that is, the total number of nitrogen atoms was 4, abbreviated as tetra-N(3)-Br. Will C 16 B (product of Solvay (Zhangjiagang) Fine Chemicals Co., Ltd.) was purified to obtain a white powdery product with a purity>98%. The surface tension of its aqueous solution was measured at 25°C as a function of concentration to obtain a surface tension-concentration curve. Then at different concentrations of C 16 Add 0.5% nano-silica particles (HL-200, Wuxi Jinding Longhua Co., Ltd., Wuxi Jinding Longhua Company, purity>99.8%, BET area: 200±20m 2 / g), ultrasonically disperse, mix and shake at 25°C for 24 hours to reach adsorption equilibrium, and measure the surface tension of the dispersion. Since the surfactant is adsorbed by the particles, the equilibrium concentra...

Embodiment 2

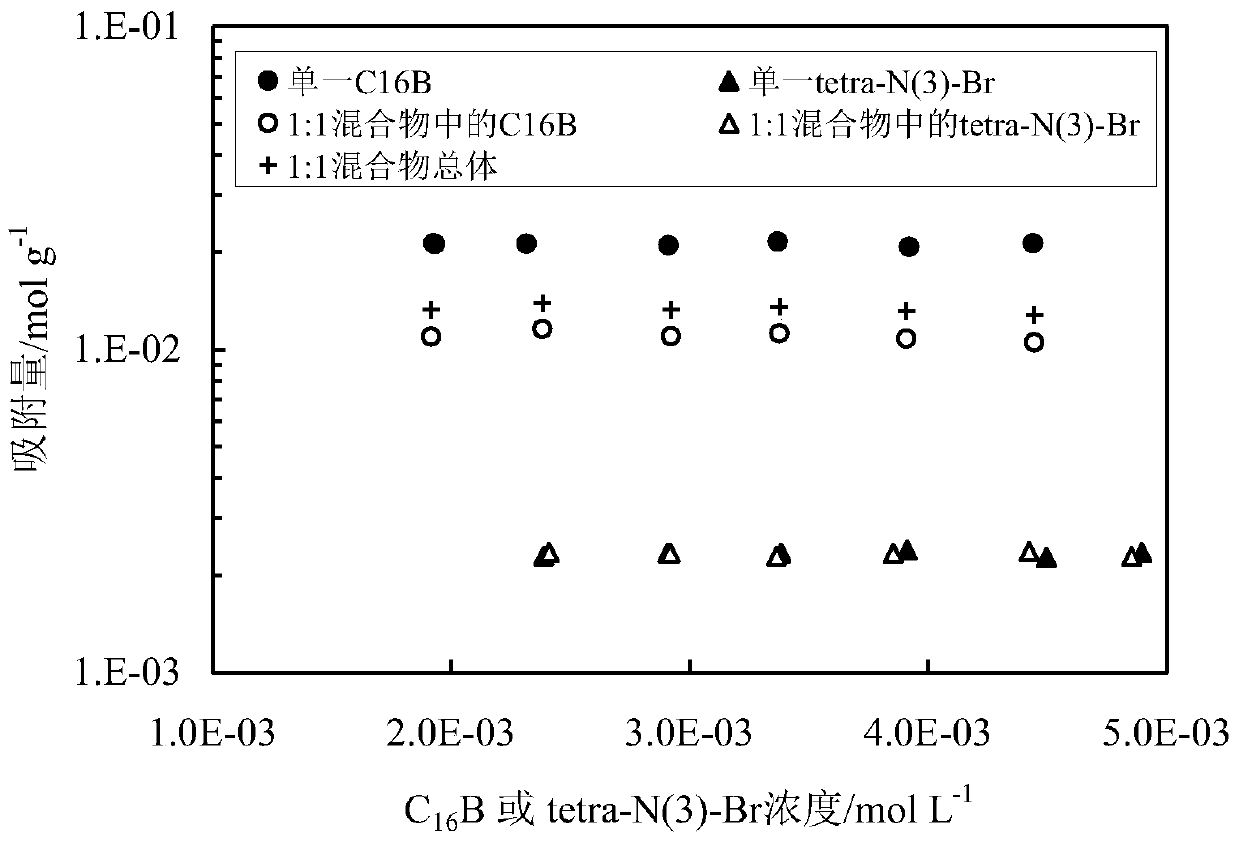

[0022] Example 2, tetra-N(3)-Br inhibits C 16 B Saturated adsorption at Daqing oil sands / water interface. Use a 50mL volumetric flask to prepare a series of different concentrations of C 16 B aqueous solution, wherein the water is deionized water. Take a 25mL sample bottle, add 1g (accurate to 0.001g) of Daqing oil sand, and then add 20mL of LC 16B aqueous solution (solid / liquid weight ratio = 1 / 20), ultrasonically disperse the particles, then fix the sample bottle on a vertical mixer, and roll and shake at 60 rpm in a constant temperature incubator at 45°C for 24 hours to achieve adsorption balance. Take off the sample bottle and put it in a constant temperature box at 45°C for more than 4 hours to allow the oil sand to fully settle. Take the supernatant and centrifuge to remove the residual particles, and measure the C in the supernatant by high pressure liquid chromatography. 16 The equilibrium concentration of B was calculated to obtain its adsorption amount. Will C ...

Embodiment 3

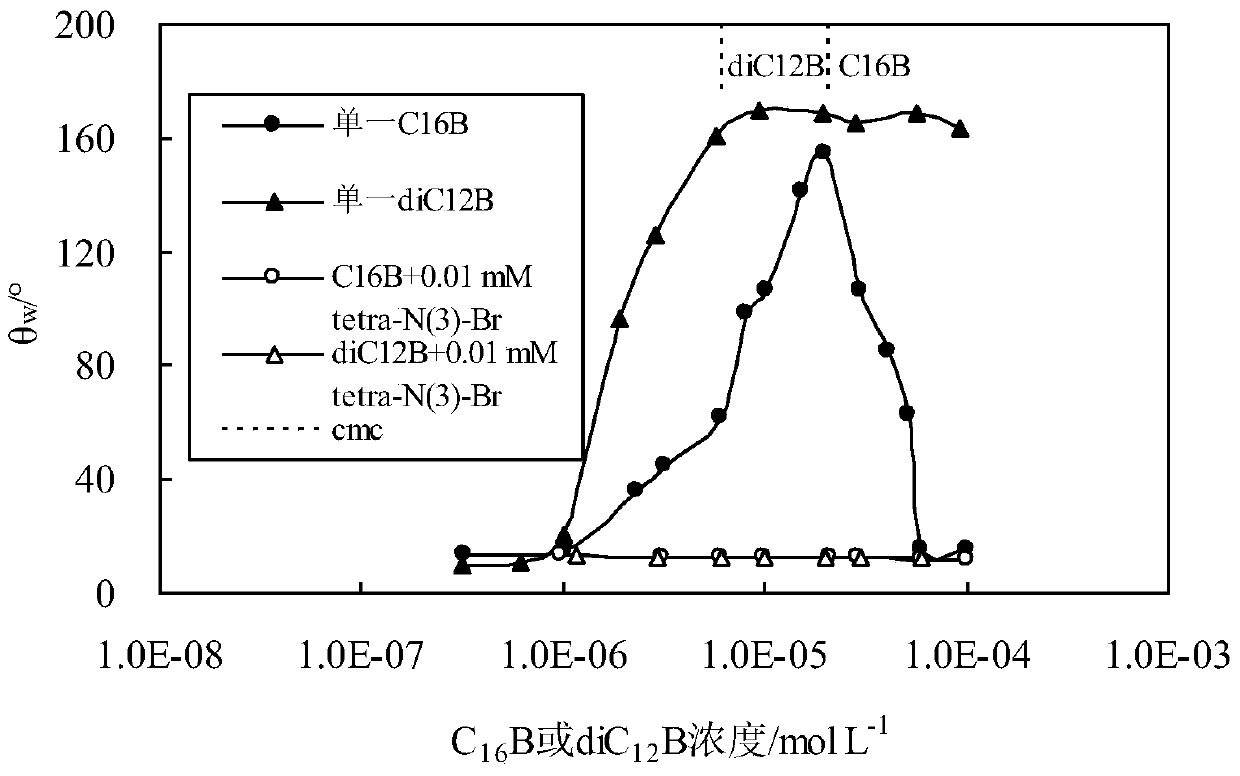

[0023] Example 3, C 16 B and diC 12 B forms a hydrophobic adsorption film on the negatively charged glass slide surface. Cut the glass slide into small pieces with a width of about 15mm, soak them in 30% NaOH aqueous solution for 24 hours, take them out, wash them with pure water until the surface is neutral, and put them into 30mm (L) with tweezers after the surface is dry. × 20mm (D) × 15mm (H) in a square glass box without a cover, supported by glass legs at both ends. Add C to the glass box 16 B or diC 12 Aqueous solution B was soaked at 25°C for 24 hours to achieve adsorption equilibrium, and then a U-shaped needle (0.25mm inner diameter) was used to release a n-decane oil droplet with a volume of 1 μL in the aqueous solution below the glass slide. Due to the effect of buoyancy, the oil droplet floats up and is captured by the glass slide to form a reverse sitting drop, take a picture, use the software to calculate the contact angle of the oil droplet, and then calcul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com