Titanium dioxide nanometer catalyst and preparation and application thereof

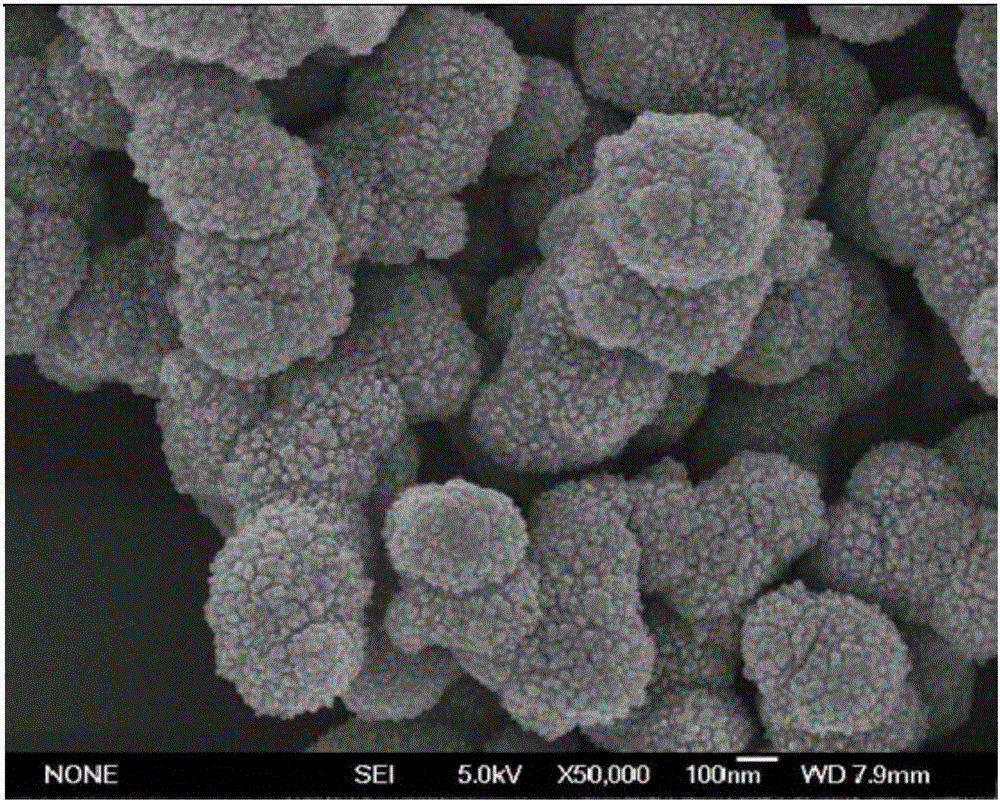

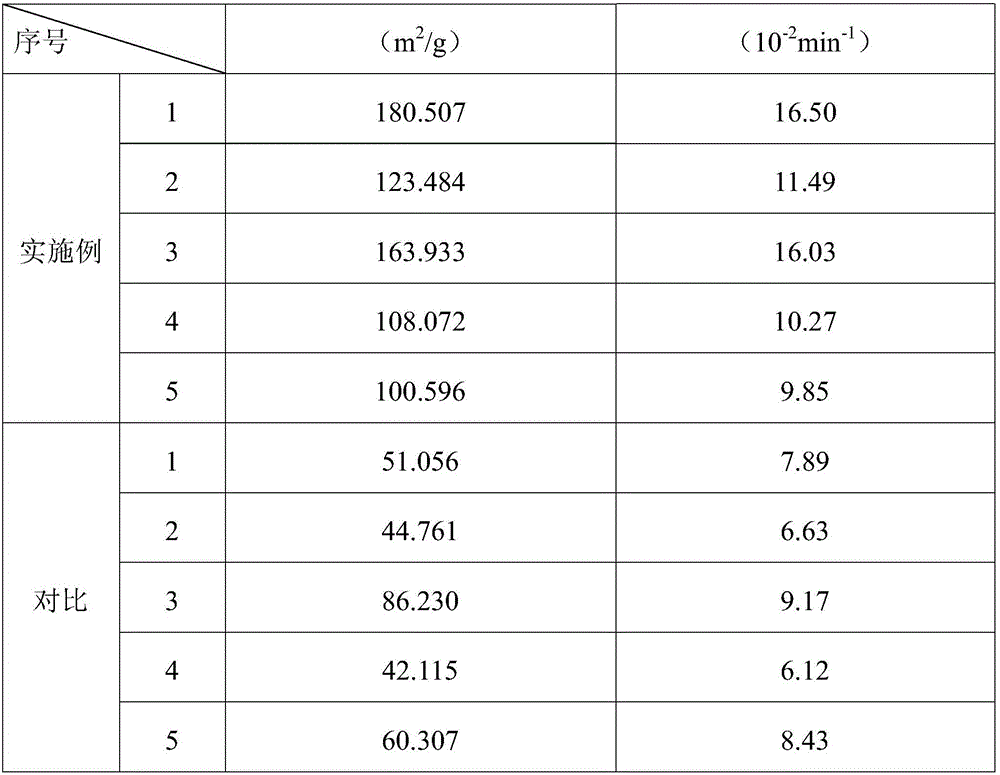

A nano-catalyst, titanium dioxide technology, applied in the field of materials, can solve the problem of insufficient degradation rate of photocatalyst, achieve the effect of improving redox ability, promoting reaction mass transfer, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The method for preparing titanium dioxide nano-catalysts assisted by the microwave comprises the following steps:

[0049] (1) Add 1.0 mL of titanyl sulfate dropwise to 100 mL of continuously stirring deionized water to disperse, and at the same time slowly add 1.0 mL of sulfuric acid to adjust the pH to 2;

[0050] (2) Place the mixed solution obtained in step (1) in a microwave reactor under normal pressure for microwave irradiation, the reaction temperature is 80°C, the reaction power is 80W, and the reaction time is 10min. After the reaction is completed, cool to room temperature to obtain milky white suspension;

[0051] (3) The milky white solution obtained in step (2) is centrifuged and washed, and repeatedly centrifuged and washed with deionized water and ethanol until the solution is washed with Ba 2+ SO cannot be detected 4 2- until;

[0052] (4) Vacuum-dry the obtained white precipitate at 50° C. for 12 hours to completely remove moisture;

[0053] (5) P...

Embodiment 2

[0056] The method for preparing titanium dioxide nano-catalysts assisted by the microwave comprises the following steps:

[0057] (1) Add 1.2mL of titanyl sulfate dropwise to 100mL of constantly stirring mixture of ethanol and deionized water to disperse, wherein the volume ratio of ethanol and deionized water is 1:5, and slowly add 2.5mL of acetic acid dropwise to adjust pH is 3.5;

[0058] (2) Place the mixed solution obtained in step (1) in a microwave reactor under normal pressure for microwave irradiation, the reaction temperature is 70°C, the reaction power is 240W, and the reaction time is 30min. After the reaction is completed, cool to room temperature to obtain milky white suspension;

[0059] (3) centrifuging and washing the milky white solution obtained in step (2), and repeatedly centrifuging and washing with deionized water and ethanol to remove the completely reacted solvent;

[0060] (4) Vacuum-dry the obtained white precipitate at 70° C. for 8 hours to comple...

Embodiment 3

[0063] The method for preparing titanium dioxide nano-catalysts assisted by the microwave comprises the following steps:

[0064] (1) Add 15 mL of titanium isopropanol dropwise to 150 mL of continuously stirring ethanol to disperse, at the same time slowly add hydrochloric acid to adjust the pH to 2, stir at room temperature for 2 hours, and obtain TiO 2 Sol;

[0065] (2) TiO obtained in step (1) 2 The sol was placed in a microwave reactor under normal pressure for microwave irradiation, the reaction temperature was 100°C, the reaction power was 160W, and the reaction time was 60min. After the reaction was completed, it was cooled to room temperature to obtain a white precipitate;

[0066] (3) centrifuging and washing the white precipitate obtained in step (2), and repeatedly centrifuging and washing with deionized water until the solution is completely neutralized;

[0067] (4) Vacuum-dry the obtained white precipitate at 50° C. for 12 hours to completely remove moisture; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com