Vanadium-doped silica-based mesoporous molecular sieve catalyst and its preparation method and application

A technology of mesoporous molecular sieve and catalyst, which is applied in the field of vanadium-doped silica-based mesoporous molecular sieve catalyst and its preparation, and can solve the problems such as the difficulty in synthesizing KIT-6 materials and the inability to enter the framework of mesoporous molecular sieves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

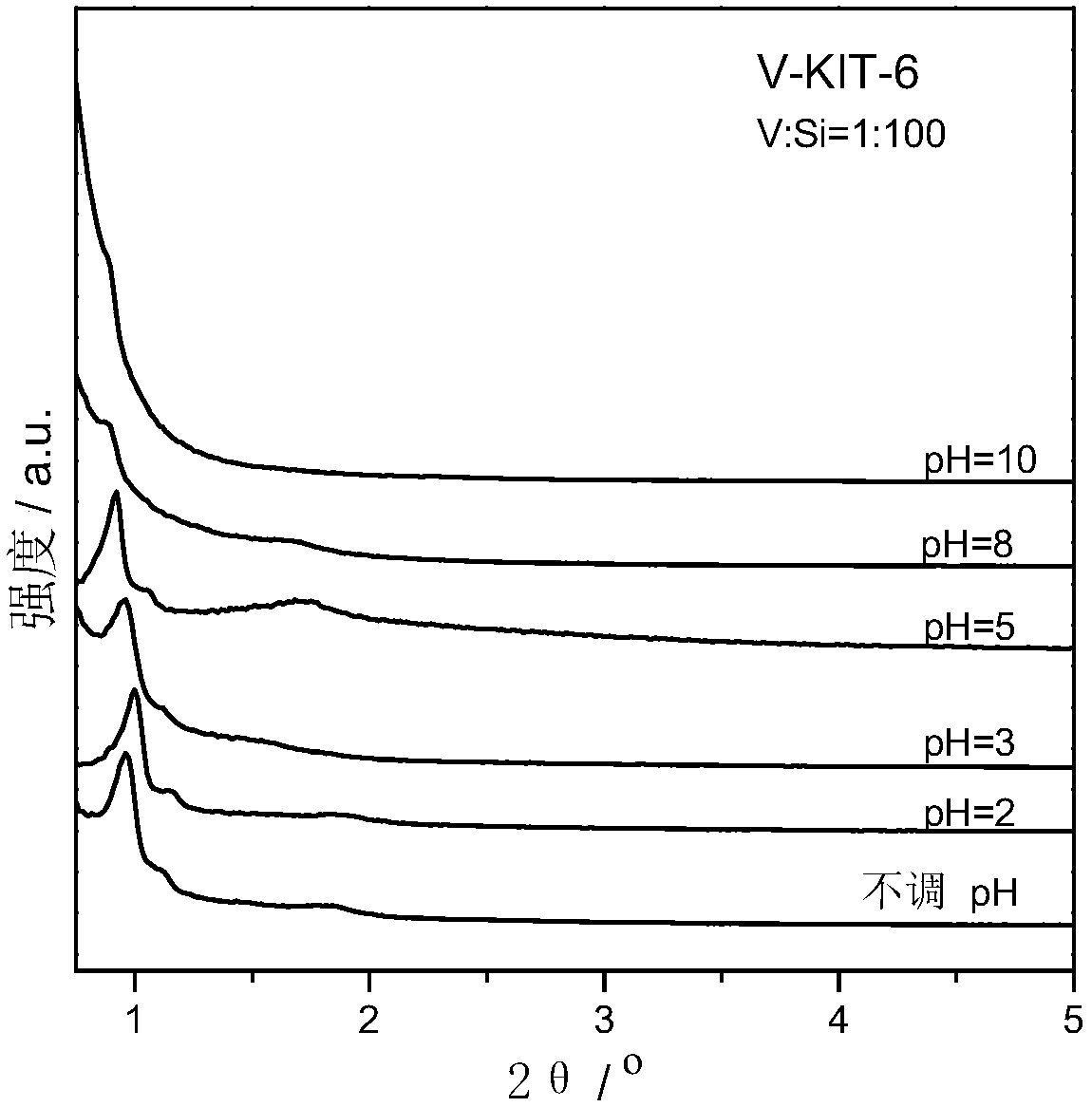

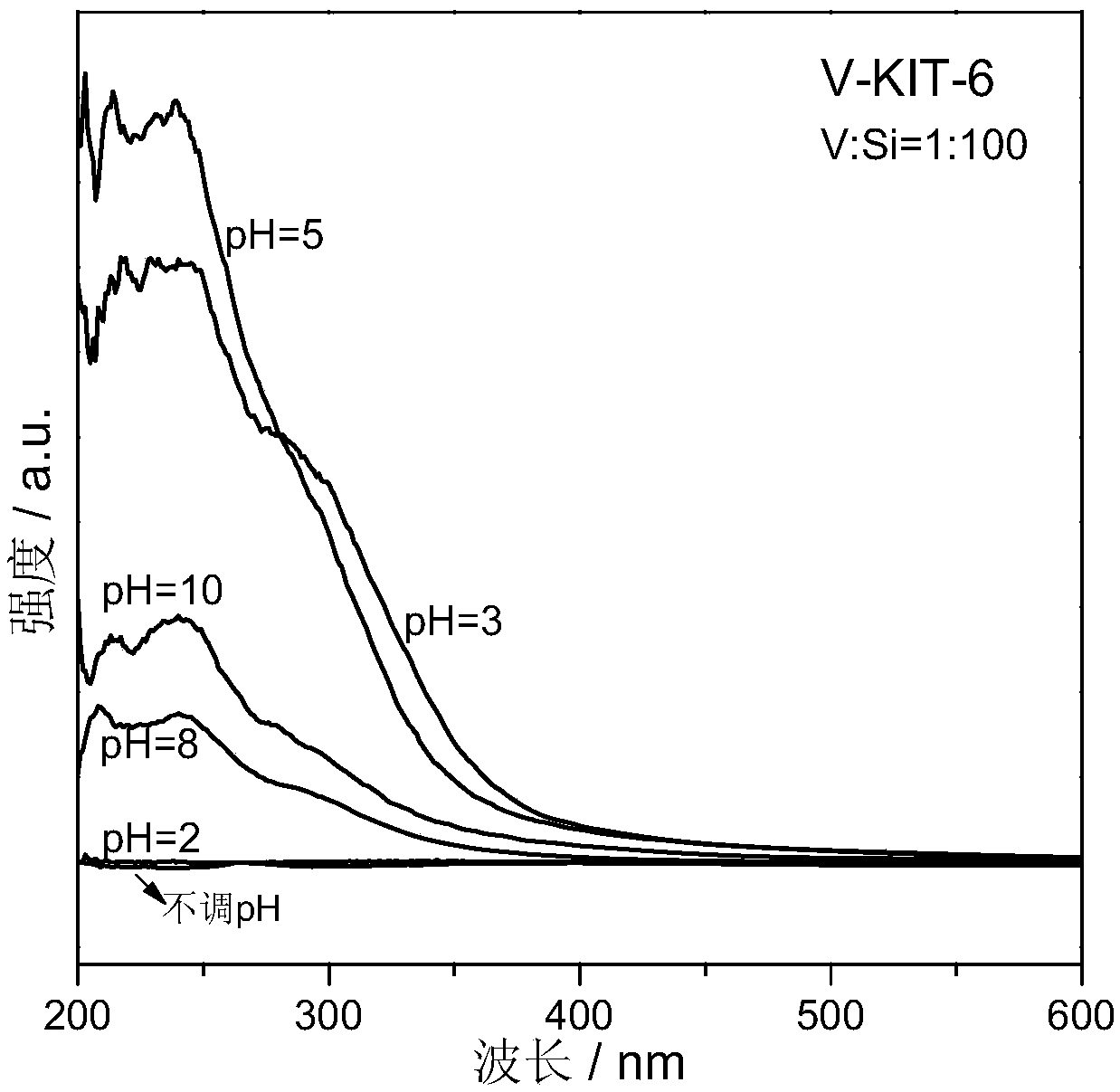

[0138] This embodiment provides the preparation method of V-KIT-6 catalyst with V and Si molar ratio of 1:100 under six different pH values, which is prepared according to the following steps:

[0139] (1) Preparation of template solution: Dissolve 2 g of triblock copolymer P123 template in 19 g of hydrochloric acid with a molar concentration of 2.0 mol / L, and stir magnetically in a constant temperature water bath at 35°C for 4 hours to make the triblock copolymer The P123 template is completely dissolved to form a homogeneous solution to obtain a triblock copolymer P123 template solution;

[0140] Six identical homogeneous triblock copolymer P123 template solutions were prepared using the same operating conditions.

[0141] (2) Preparation of vanadium source solution: Weigh 0.036 g of ammonium metavanadate, mix it with 57 g of deionized water, and stir magnetically in a constant temperature water bath at 35° C. to form a uniform solution to obtain ammonium metavanadate soluti...

Embodiment 2

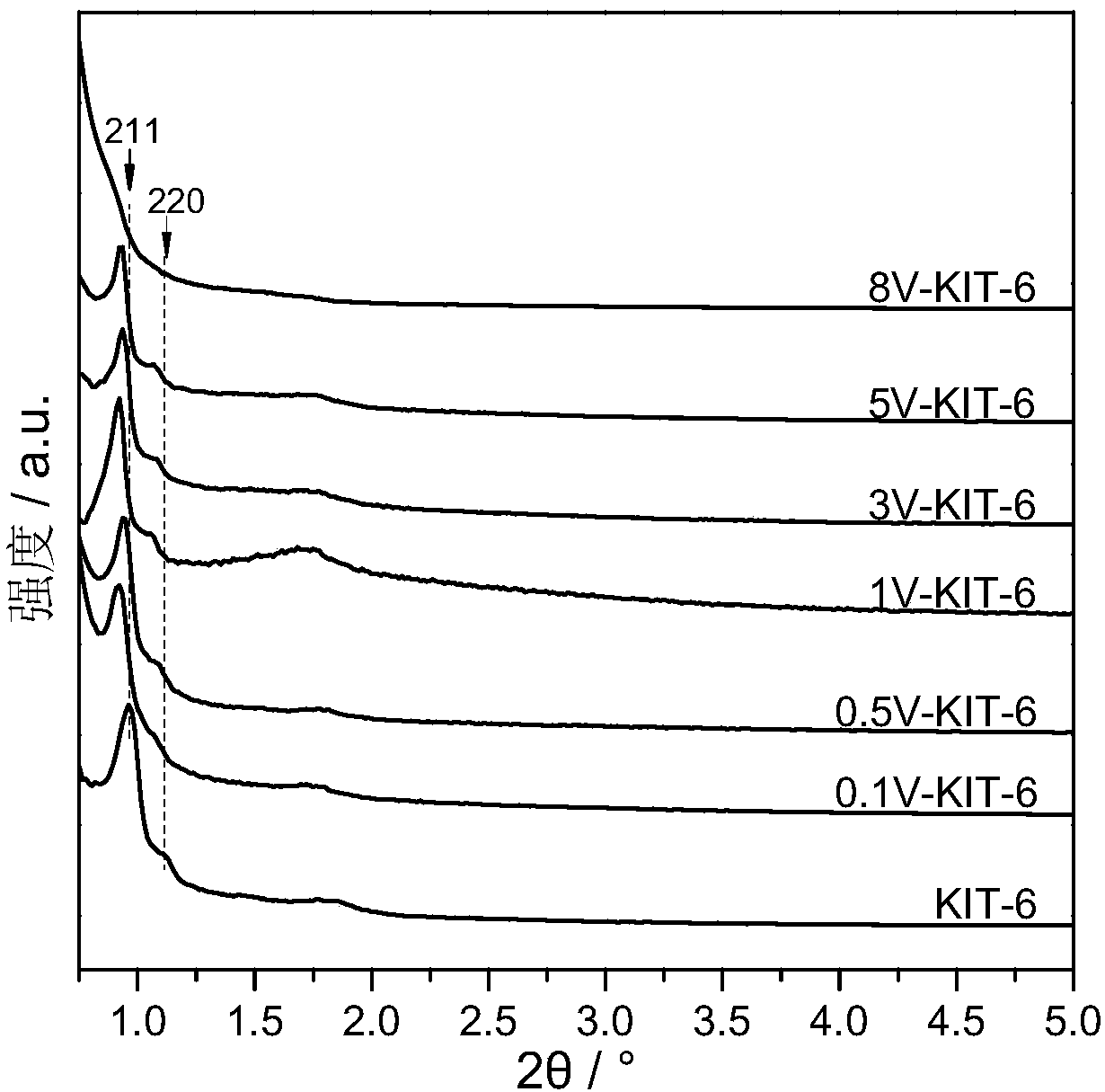

[0151] This example provides six kinds of vanadium doped The preparation method of KIT-6 mesoporous molecular sieve catalyst, its preparation method comprises the following steps:

[0152] (1) Preparation of template solution: Dissolve 2 g of triblock copolymer P123 template in 19 g of hydrochloric acid with a molar concentration of 2.0 mol / L, and stir magnetically in a constant temperature water bath at 35°C for 4 hours to make the triblock copolymer The P123 template is completely dissolved to form a homogeneous solution to obtain a triblock copolymer P123 template solution;

[0153] Six identical homogeneous triblock copolymer P123 template solutions were prepared using the same operating conditions.

[0154] (2) Preparation of vanadium source solution: Weigh 0.004g, 0.018g, 0.036g, 0.108g, 0.180g and 0.288g of ammonium metavanadate respectively, mix them with 57g of deionized water, and place them in a constant temperature water bath at 35°C Stir with medium magnetic for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com