Pretreatment method suitable for evaporative crystallization of landfill leachate stock solution

A landfill leachate and pretreatment technology, applied in the direction of contaminated groundwater/leachate treatment, multi-stage water treatment, water/sewage treatment, etc., can solve evaporator scaling, excessive turbidity, and heat exchanger blockage and other problems, to achieve the effects of slowing down heat exchanger blockage, stable effect, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Taking the leachate raw liquid of a waste incineration plant in Beijing as the processing object, its parameters are: COD is 72000~76000mg / L, ammonia nitrogen is 2200~2500mg / L, turbidity is 5400~6300NTU, SS is 8000~12000mg / L, The pH is 5.97~6.13, and the conductivity is 32.4~35.6ms / cm.

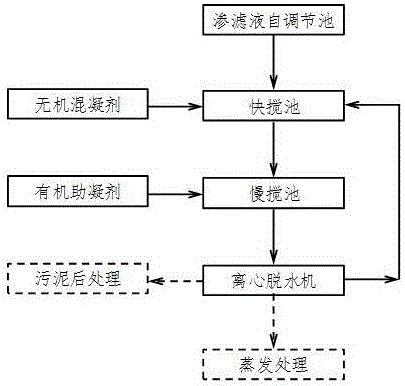

[0029] like figure 1 As shown, the pretreatment method suitable for landfill leachate stoste evaporation crystallization of the present invention comprises the following steps:

[0030] First, the stock solution of the landfill leachate is sent to the quick stirring tank, and the inorganic coagulant PAC of 8g / L is added in the quick stirring tank, and the centrifuge liquid of 0.6 times of the stock solution feeding amount is fully and quickly mixed so that all Most of the suspended matter and colloidal pollutants in the raw liquid of landfill leachate flocculate to form a large number of tiny flocs. The residence time of the quick stirring pool is 1min, and the stirring speed is 180r / ...

Embodiment 2

[0035] Taking the leachate raw liquid of a waste incineration plant in Beijing as the processing object, its parameters are: COD is 72000~76000mg / L, ammonia nitrogen is 2200~2500mg / L, turbidity is 5400~6300NTU, SS is 8000~12000mg / L, The pH is 5.97~6.13, and the conductivity is 32.4~35.6ms / cm.

[0036] like figure 1 As shown, the pretreatment method suitable for landfill leachate stoste evaporation crystallization of the present invention comprises the following steps:

[0037] First, the stock solution of the landfill leachate is sent to the quick stirring tank, and the inorganic coagulant PAC of 5g / L is added in the quick stirring tank, and the centrifugal supernatant of 1.2 times of the stock solution feeding amount is fully and quickly mixed so that all Most of the suspended matter and colloidal pollutants in the raw liquid of landfill leachate flocculate to form a large number of tiny flocs. The residence time of the quick stirring tank is 3min, and the stirring speed is...

Embodiment 3

[0042] Taking the leachate raw liquid of a waste landfill in Heilongjiang as the processing object, its parameters are: COD is 17600~36000mg / L, ammonia nitrogen is 2700~2900mg / L, turbidity is 3500~5000NTU, SS is 3000~6000mg / L , pH is 7.1~7.5, conductivity is 25.6~28.3ms / cm.

[0043] like figure 1 As shown, the pretreatment method suitable for landfill leachate stoste evaporation crystallization of the present invention comprises the following steps:

[0044] First, the stock solution of the landfill leachate is sent into a quick stirring tank, and 3 g / L of inorganic coagulant PAC and 2.5 times of the feed amount of the stock solution are added to the quick stirring tank, and after fully and quickly mixing, all the Most of the suspended matter and colloidal pollutants in the raw liquid of landfill leachate flocculate to form a large number of tiny flocs. The residence time of the quick stirring tank is 3min, and the stirring speed is 250r / min.

[0045] Secondly, the landfill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com