Preparation method of water-borne polyacrylate for emitting room temperature phosphorescence

The technology of polyacrylate and polyacrylate emulsion is applied in the field of preparation of polyacrylate, which can solve the problems of restricting large-scale popularization and application, poor acid and alkali resistance, complex synthesis, etc. The effect of low mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

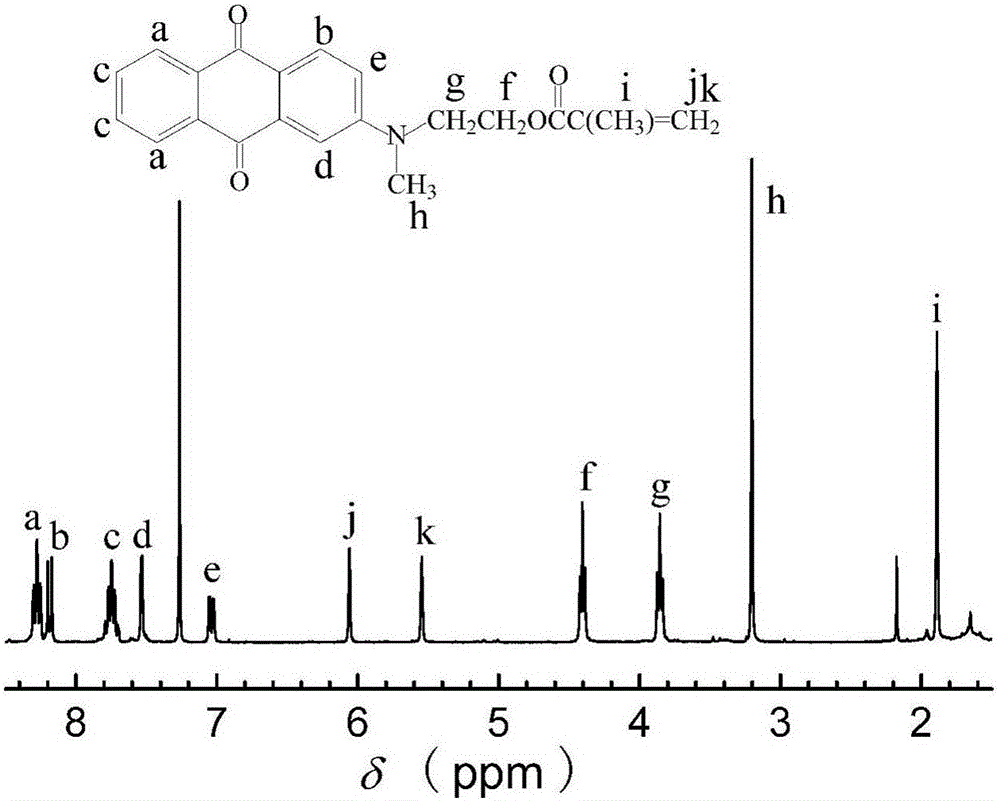

[0031] 1. Add 2.1g of 2-chloroanthraquinone, 2.0g of N-methyldiethanolamine and 0.72g of potassium hydroxide into a 50mL single-necked bottle, stir and raise the temperature to 130°C for 10 hours; after the reaction system is cooled to room temperature, the reactant Pour it into a 250mL beaker with 100mL of distilled water and a magnetic stirrer, stir rapidly for 1h; filter and collect the reddish-brown solid precipitate, recrystallize with ethanol or toluene to obtain 2.11g of pure reddish-brown solid intermediate 2 -[(2-Hydroxyethyl)-methylamino]-anthraquinone, yield 89%.

[0032]2. Add 1.69g 2-[(2-hydroxyethyl)-methylamino]-anthraquinone, 0.91g triethylamine and 15g dichloromethane into a 50mL single-necked bottle, stir at room temperature until the solid is completely dissolved; add 1.25g 2- Dissolve methacryloyl chloride in 5mL of dichloromethane, add it dropwise to the one-necked bottle under stirring at room temperature, and keep it for 30 minutes to complete the drop, ...

Embodiment 2

[0039] Add 1.21g of sodium lauryl sulfate and 30g of distilled water into a 150mL three-necked flask, stir and emulsify for 15 minutes; add 0.202g of the phosphorescent chromophore-containing acrylate ANAQ, 2gBMA and 2gHEA prepared above into the three-necked flask for emulsification 30 minutes; heat up the reaction system to 60°C, dissolve 0.4g AIBI in 10g distilled water; add the AIBI aqueous solution, 8g butyl methacrylate and 8g hydroxyethyl acrylate mixed monomer into the three-necked flask dropwise within 2 hours ; After 6 hours of heat preservation and stirring, a butyl methacrylate-hydroxyethyl acrylate-phosphorescent acrylate terpolymer (ANAQ-WPA-1) with an ANAQ content of 1 wt% can be obtained.

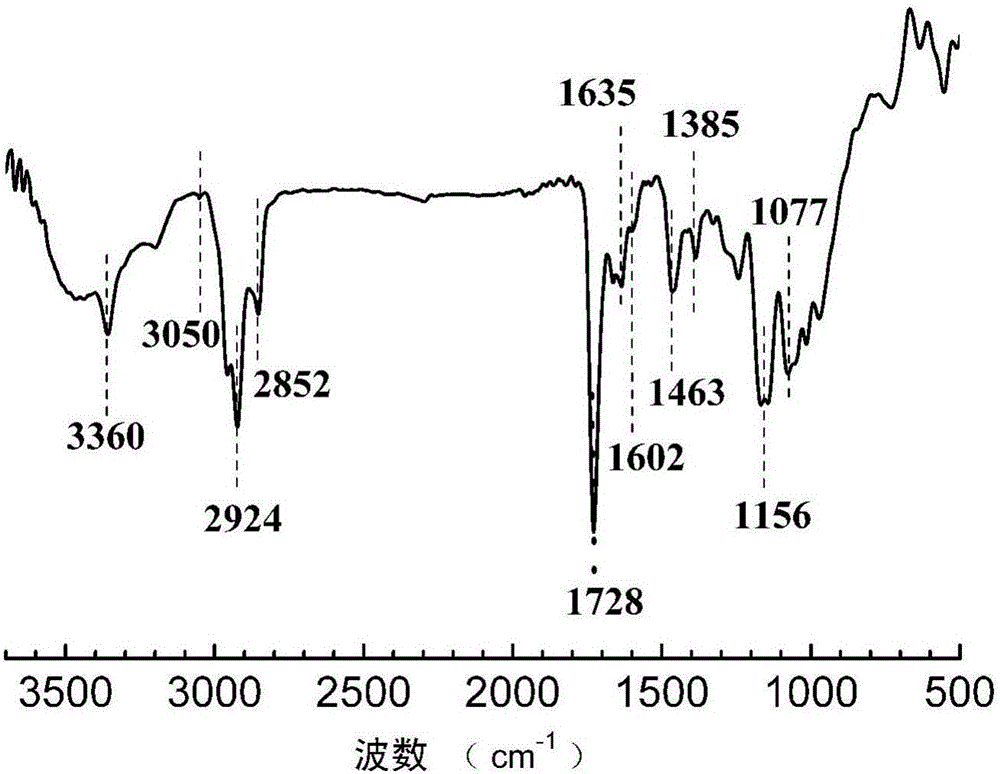

[0040] figure 2 It is the Fourier (Fourier) of the ternary copolymerized water-based polyacrylate that can emit room temperature phosphorescence prepared in this embodiment, that is, butyl methacrylate-hydroxyethyl acrylate-phosphorescent acrylate terpolymer (ANAQ-WPA-1). ...

Embodiment 3

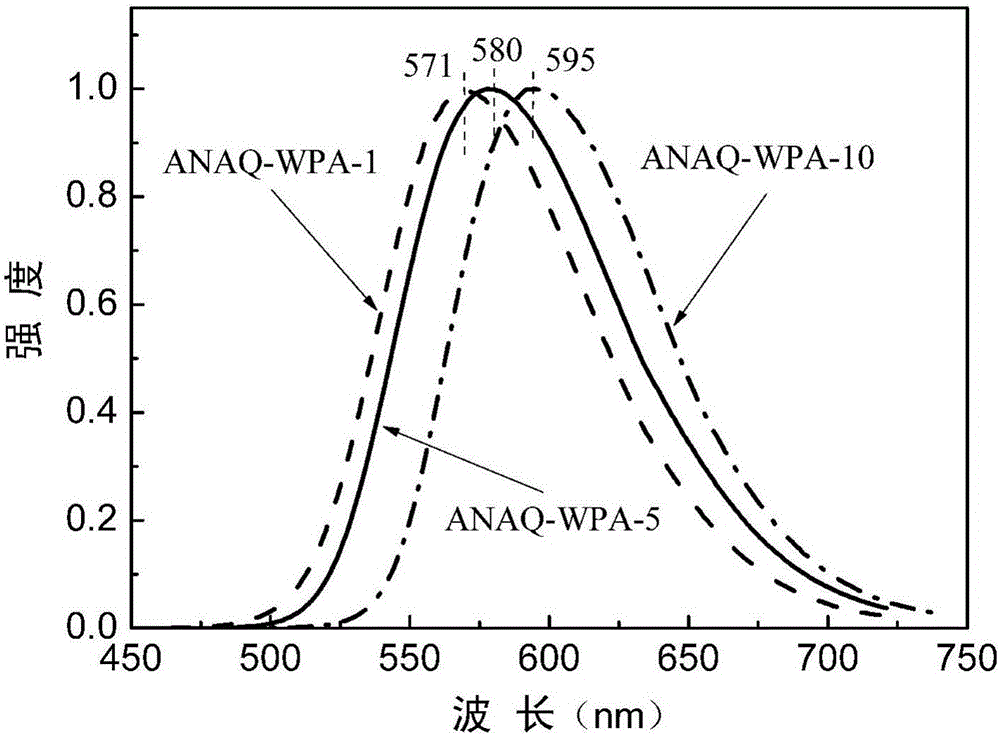

[0042] Add 2g sodium lauryl sulfate and 30g distilled water into a 150mL three-necked flask, stir and emulsify for 15 minutes; add 2g of ANAQ, 2gBMA and 2g HEA prepared above into the three-necked flask for emulsification for 30 minutes; raise the temperature of the reaction system to 60°C, Dissolve 0.4g of AIBI in 10g of distilled water; drop AIBI aqueous solution, 7g of butyl methacrylate and 7g of hydroxyethyl acrylate mixed monomer into a three-necked flask and finish dropping within 2 hours; after insulated and stirred for 6 hours, the content of ANAQ obtained is 10% butyl methacrylate-hydroxyethyl acrylate-phosphorescent acrylate terpolymer (ANAQ-WPA-10); after film formation, a copolymerized water-based polyacrylate film emitting room temperature phosphorescence in vacuum can be obtained.

[0043] If other conditions remain unchanged and the mass ratio of phosphorescent acrylate monomer and comonomer is changed, a series of copolymerized water-based polyacrylates with di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com