A kind of preparation method of waterborne polyacrylate emitting room temperature phosphorescence

A technology for polyacrylate and polyacrylate emulsion, which is applied in the field of polyacrylate preparation, can solve the problems of restricting large-scale popularization and application, poor acid and alkali resistance, high price, etc., and achieves advantages of large-scale production and low cost. , Long-lasting and stable luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Add 2.1g 2-chloroanthraquinone, 2.0g N-methyldiethanolamine and 0.72g potassium hydroxide into a 50mL single-necked bottle, stir and heat up to 130°C for 10 hours; wait for the reaction system to cool to room temperature, put Pour the reactant into a 250mL beaker filled with 100mL distilled water and a magnetic stirrer, and stir rapidly for 1h; filter and collect the reddish-brown solid precipitate, recrystallize with ethanol or toluene to obtain 2.11g of pure reddish-brown solid intermediate The product 2-[(2-hydroxyethyl)-methylamino]-anthraquinone has a yield of 89%.

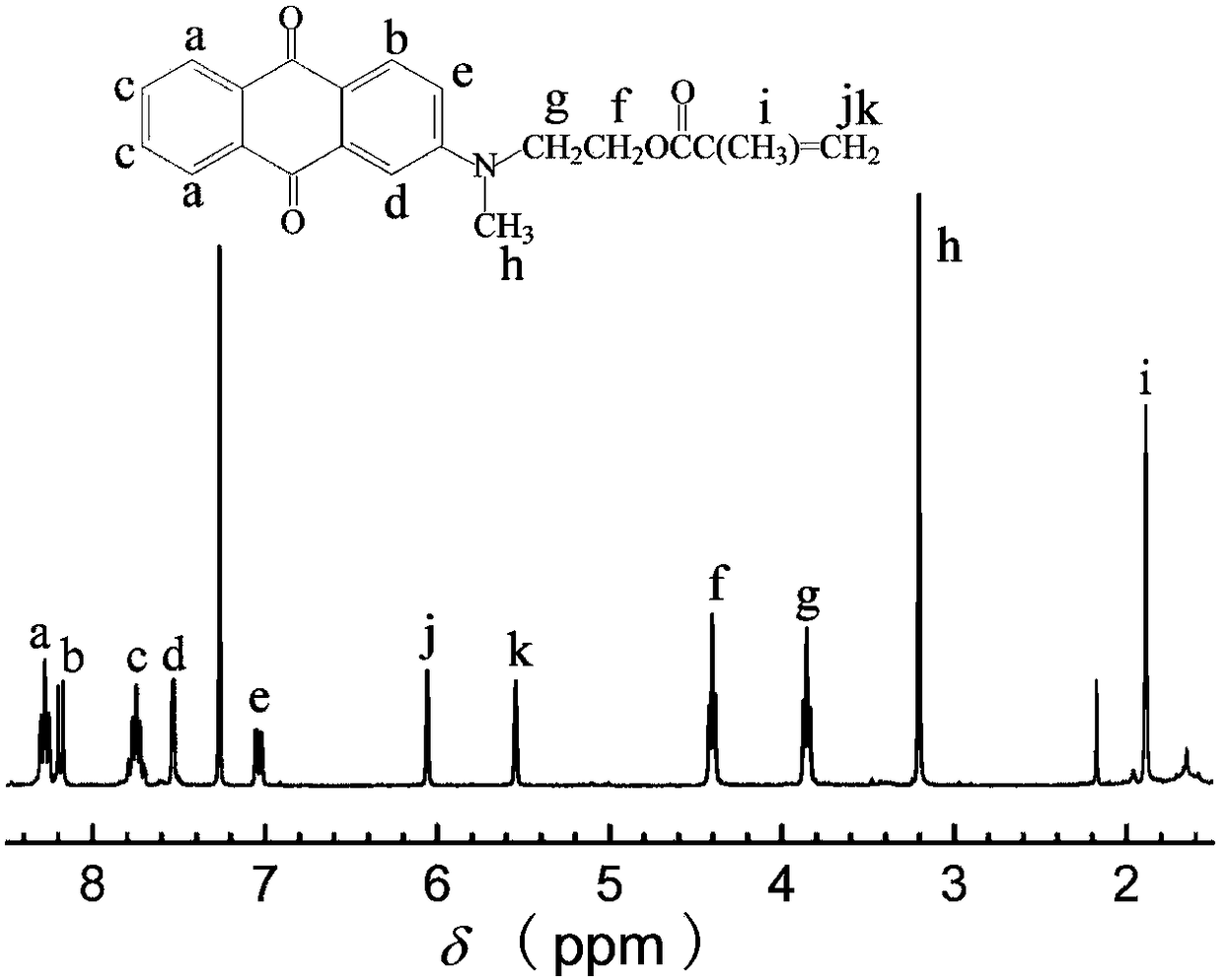

[0032]2. Add 1.69g 2-[(2-hydroxyethyl)-methylamino]-anthraquinone, 0.91g triethylamine and 15g dichloromethane into a 50mL single-necked bottle, stir at room temperature until the solid is completely dissolved; -Dissolve methacryloyl chloride in 5mL of dichloromethane, add it dropwise to the one-necked bottle under stirring at room temperature, and keep it for 30 minutes to complete the drop, then s...

Embodiment 2

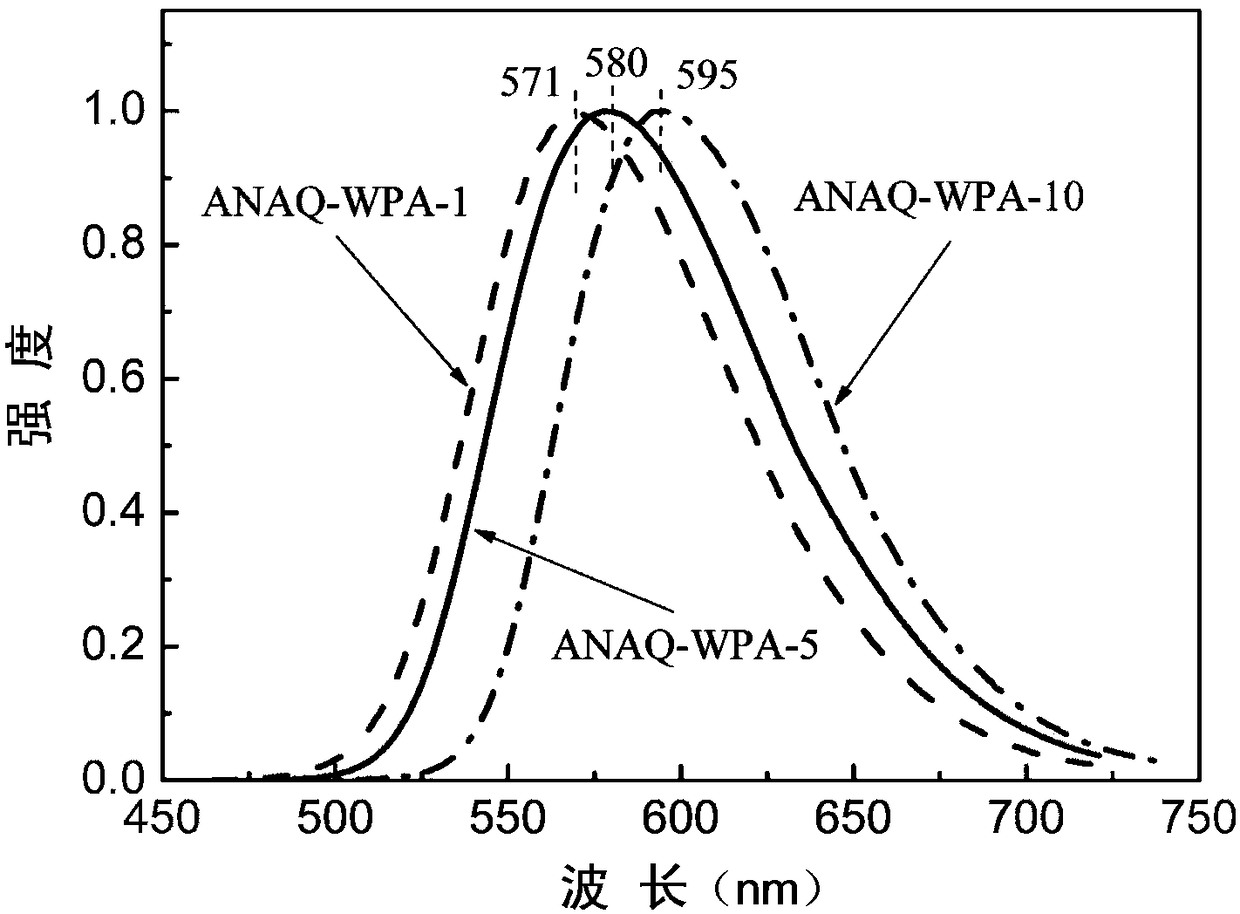

[0039] Add 1.21g of sodium lauryl sulfate and 30g of distilled water into a 150mL three-necked flask, stir and emulsify for 15 minutes; add 0.202g of the phosphorescent chromophore-containing acrylate ANAQ prepared above, 2g of BMA and 2g of HEA into the three-necked flask Emulsify in medium for 30 minutes; heat up the reaction system to 60°C, dissolve 0.4g AIBI in 10g distilled water; add AIBI aqueous solution, 8g butyl methacrylate and 8g hydroxyethyl acrylate mixed monomer into the three-necked flask for 2 hours The internal drop is completed; after 6 hours of heat preservation and stirring, a butyl methacrylate-hydroxyethyl acrylate-phosphorescent acrylate terpolymer (ANAQ-WPA-1) with an ANAQ content of 1 wt% can be obtained.

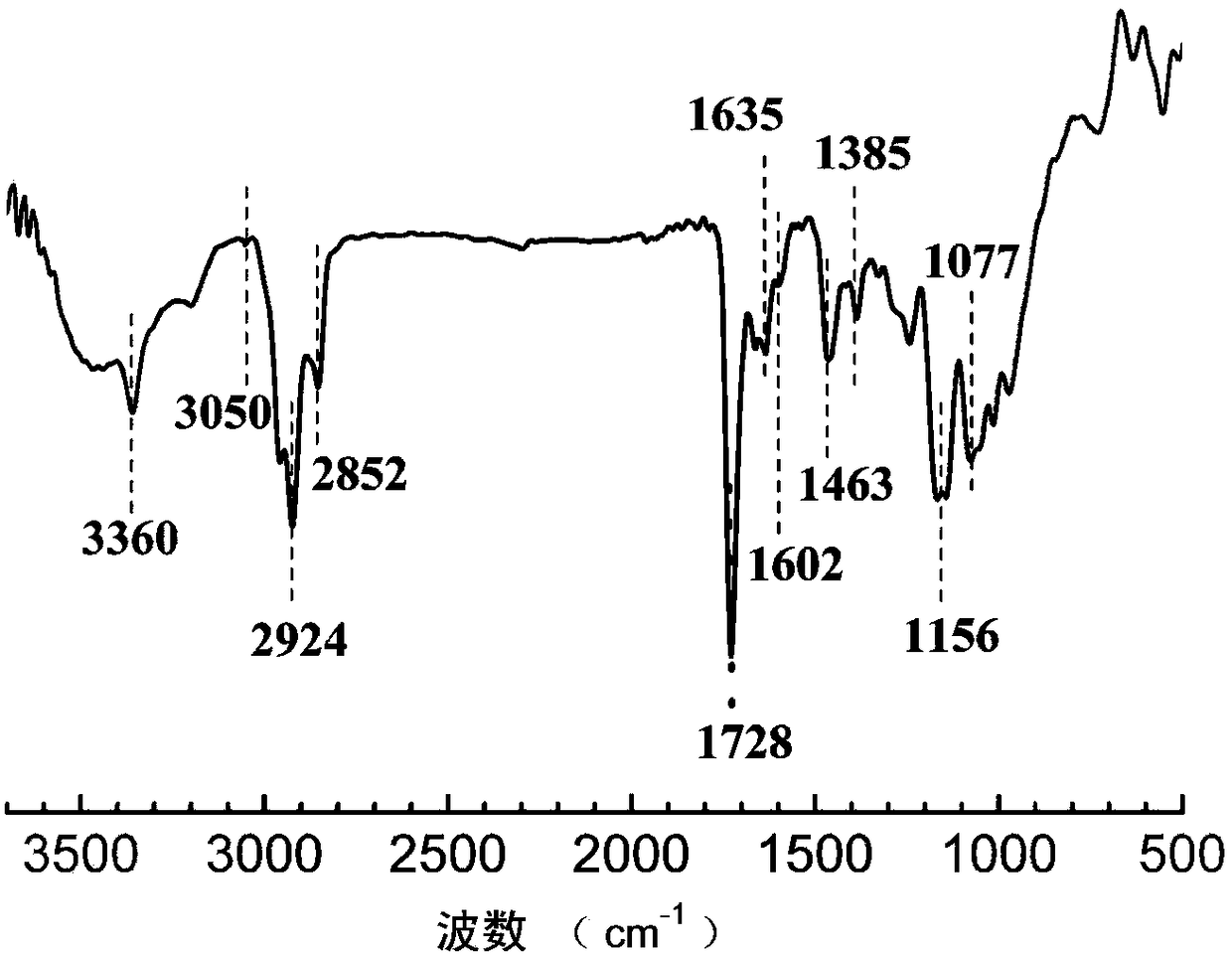

[0040] figure 2 It is the Fourier (Fourier) of the ternary copolymerized water-based polyacrylate that can emit room temperature phosphorescence prepared in this embodiment, that is, butyl methacrylate-hydroxyethyl acrylate-phosphorescent acrylate ...

Embodiment 3

[0042] Add 2g of sodium lauryl sulfate and 30g of distilled water into a 150mL three-necked flask, stir and emulsify for 15 minutes; add 2g of the above-prepared ANAQ, 2g of BMA and 2g of HEA into the three-necked flask for emulsification for 30 minutes; raise the temperature of the reaction system to 60 ℃, dissolve 0.4g AIBI in 10g distilled water; drop the AIBI aqueous solution, 7g butyl methacrylate and 7g hydroxyethyl acrylate mixed monomer into the three-necked flask and finish dropping within 2 hours; keep stirring for 6 hours to prepare Butyl methacrylate-hydroxyethyl acrylate-phosphorescent acrylate terpolymer (ANAQ-WPA-10) with an ANAQ content of 10%; after film formation, a copolymerized water-based polyacrylate that emits room temperature phosphorescence in vacuum can be obtained film.

[0043] If other conditions remain unchanged and the mass ratio of phosphorescent acrylate monomer and comonomer is changed, a series of copolymerized water-based polyacrylates with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com