Polysaccharide-base gel composite film, and preparation method and application thereof

A composite film and gel technology, used in transportation and packaging, flexible covering, packaging, etc., can solve the problems of low elongation performance and low tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Preparation process of polysaccharide gel composite film

[0035] (1) Sodium alginate, carrageenan or sodium alginate, carrageenan are mixed in a ratio of 1:1, respectively weigh 3g and dissolve in 97g of water under the action of a magnetic stirrer to obtain 3% Three kinds of polysaccharide solutions; Weigh 2g of Curdlan powder and dissolve it in 90g of pure water. After Curdlan is fully swollen, slowly add 1g of NaOH or 1.4g of KOH under the action of a magnetic stirrer, and make up to 100g with pure water. The mass percent content is 2% Curdlan solution; weigh 5g of CMC-Na, and dissolve it in 95 grams of pure water under the action of a magnetic stirrer to prepare a 5% mass percent CMC-Na solution.

[0036] (2) Take 44.5g polysaccharide solution, 40g Curdlan solution, and 15g CMC-Na solution and mix slowly, slowly add 2.5mol / L citric acid dropwise to adjust the pH value of the mixture, and add 0.5g glycerin. During the dropwise addition of the acid soluti...

Embodiment 2

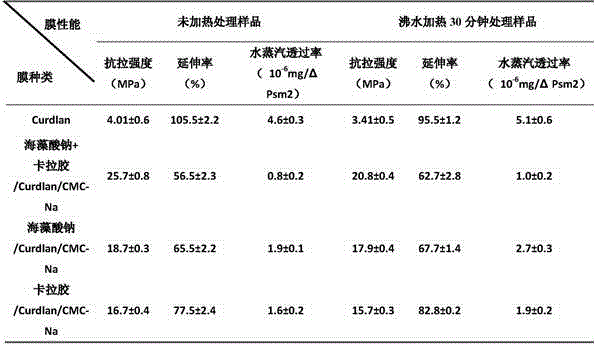

[0040] Embodiment 2: Method for measuring the properties of polysaccharide gel edible film

[0041] (1) Mechanical properties

[0042] The film was cut into strips of 8cm*2cm, and fixed on a physical property analyzer for measurement. Set the initial distance between the two fixtures of the physical property meter to 80mm, and the speed to 0.8mm / sec. After the measurement, record the force (g) at the instant the film breaks and the distance L between the two clamps when the film breaks. For each sample, five parallel samples were taken for determination.

[0043] Tensile strength TS (g) is calculated according to the following formula:

[0044] TS=Fm / d*W

[0045] Where: TS—tensile strength, (MPa);

[0046] Fm—the maximum tension that the sample bears when it breaks, (N);

[0047] d—film thickness, (m);

[0048] W—film width, (m).

[0049] The elongation at break E (%) is calculated according to the following formula:

[0050] E=(L 1 - L 0 ) / L 0

[0051] In the formu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com