Epoxy polysiloxane anticorrosive paint

A technology of epoxy polysiloxane and anti-corrosion coatings, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of obvious performance differences, slow development, and less formulations, and achieve excellent adhesion and weather resistance Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

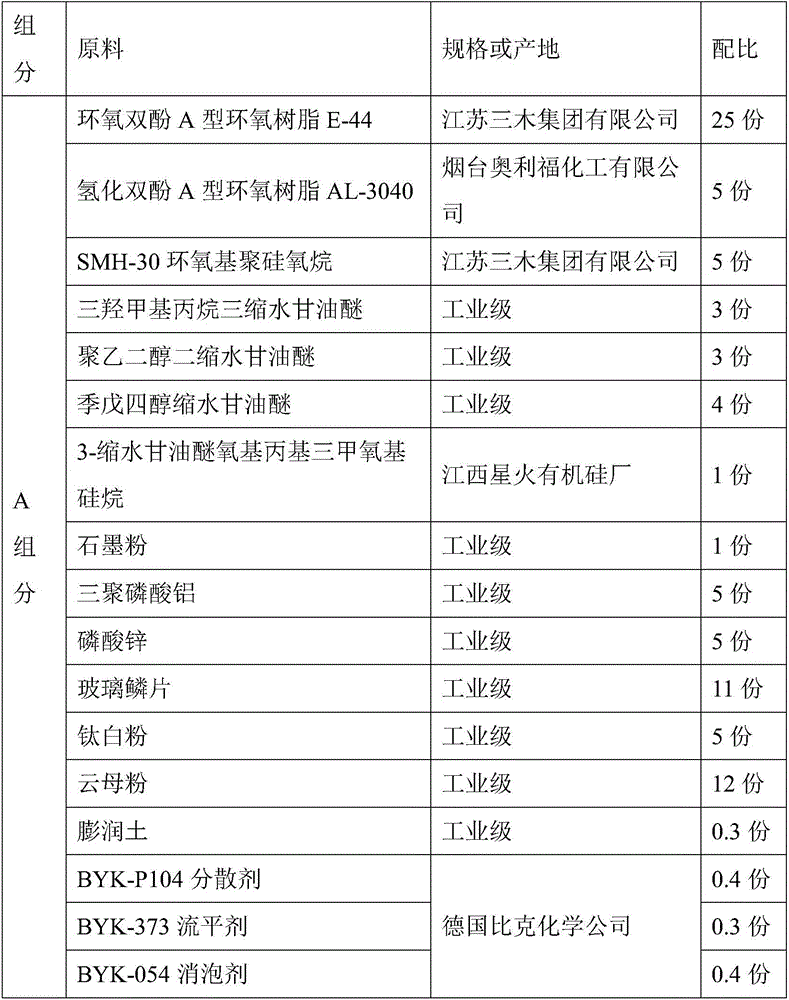

[0028] An epoxy polysiloxane anti-corrosion coating. The raw material composition that has following parts by weight:

[0029]

[0030]

[0031] The preparation method of above-mentioned epoxy polysiloxane anticorrosion coating, its step is as follows:

[0032] (1) Mix epoxy resin and epoxy polysiloxane according to the proportion, and control the heating temperature at 60°C to dissolve;

[0033] (2) Add silane coupling agent, pigment, filler, thickener, dispersant, leveling agent, defoamer, plasticizer and diluent to the above mixed resin in sequence for high-speed dispersion, and grind to a particle size of 50 Micron, adjust viscosity with active diluent, after cooling to room temperature, get A component.

[0034] (3) Mix component A and component B cashew nut shell oil modified amine curing agent according to the above ratio before use.

Embodiment 2

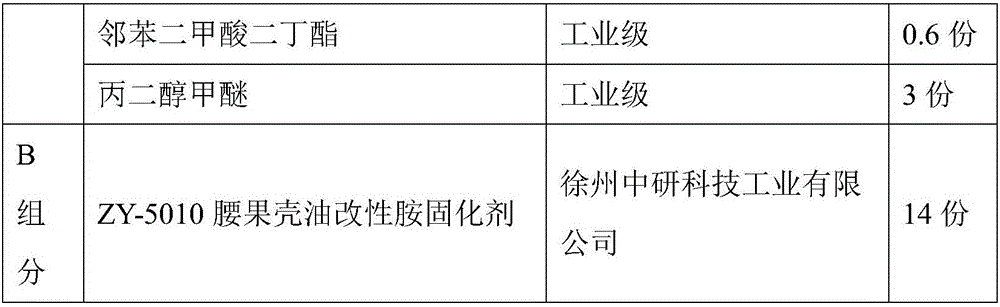

[0036] An epoxy polysiloxane anti-corrosion coating. The raw material composition that has following parts by weight:

[0037]

[0038]

[0039] The preparation method of above-mentioned epoxy polysiloxane anticorrosion coating, its step is as follows:

[0040] (1) Mix epoxy resin and epoxy polysiloxane according to the proportion, and control the heating temperature at 60°C to dissolve;

[0041] (2) Add silane coupling agent, pigment, filler, thickener, dispersant, leveling agent, defoamer, plasticizer and diluent to the above mixed resin in sequence for high-speed dispersion, and grind to a particle size of 50 Micron, adjust viscosity with active diluent, after cooling to room temperature, get A component.

[0042] (3) Mix component A and component B cashew nut shell oil modified amine curing agent according to the above ratio before use.

Embodiment 3

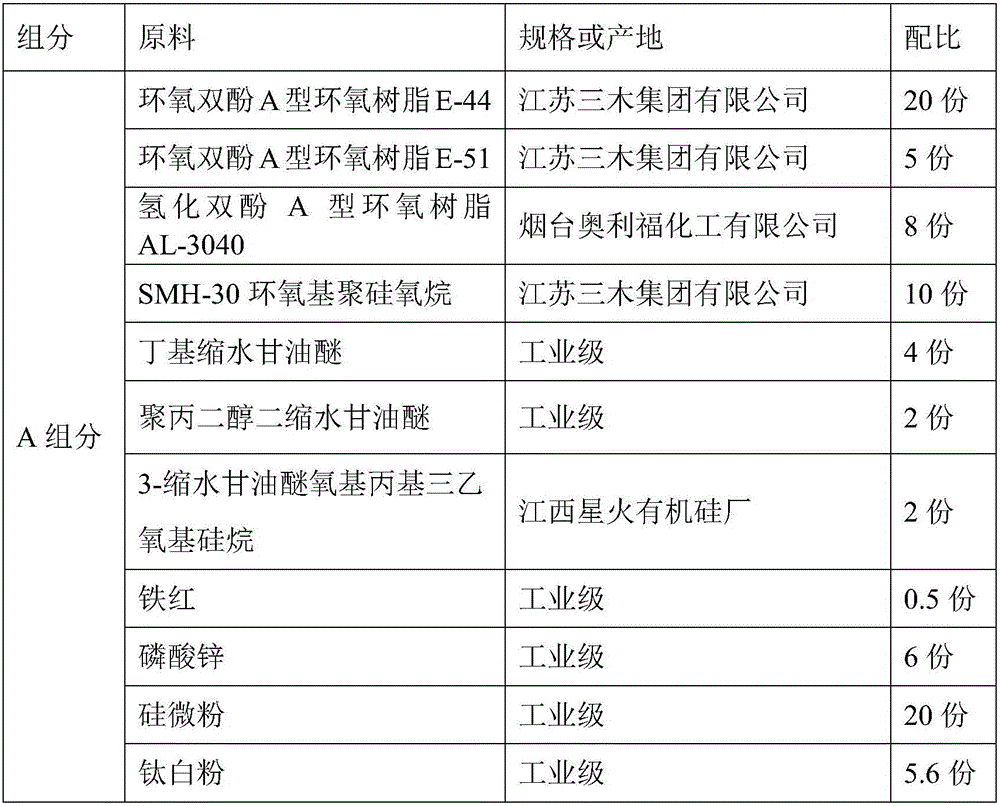

[0044] An epoxy polysiloxane anti-corrosion coating. The raw material composition that has following parts by weight:

[0045]

[0046]

[0047] The preparation method of above-mentioned epoxy polysiloxane anticorrosion coating, its step is as follows:

[0048] (1) Mix epoxy resin and epoxy polysiloxane according to the proportion, and control the heating temperature at 55°C to dissolve;

[0049] (2) Add silane coupling agent, pigment, filler, thickener, dispersant, leveling agent, defoamer, plasticizer and diluent to the above mixed resin in sequence for high-speed dispersion, and grind to a particle size of 50 Micron, adjust viscosity with active diluent, after cooling to room temperature, get A component.

[0050] (3) Mix component A and component B cashew nut shell oil modified amine curing agent according to the above ratio before use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com